Method for producing aldehyde-free by wood

A production method and technology of plywood, applied in the direction of joining wooden veneers, manufacturing tools, adhesive application devices, etc., can solve problems that threaten people's health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

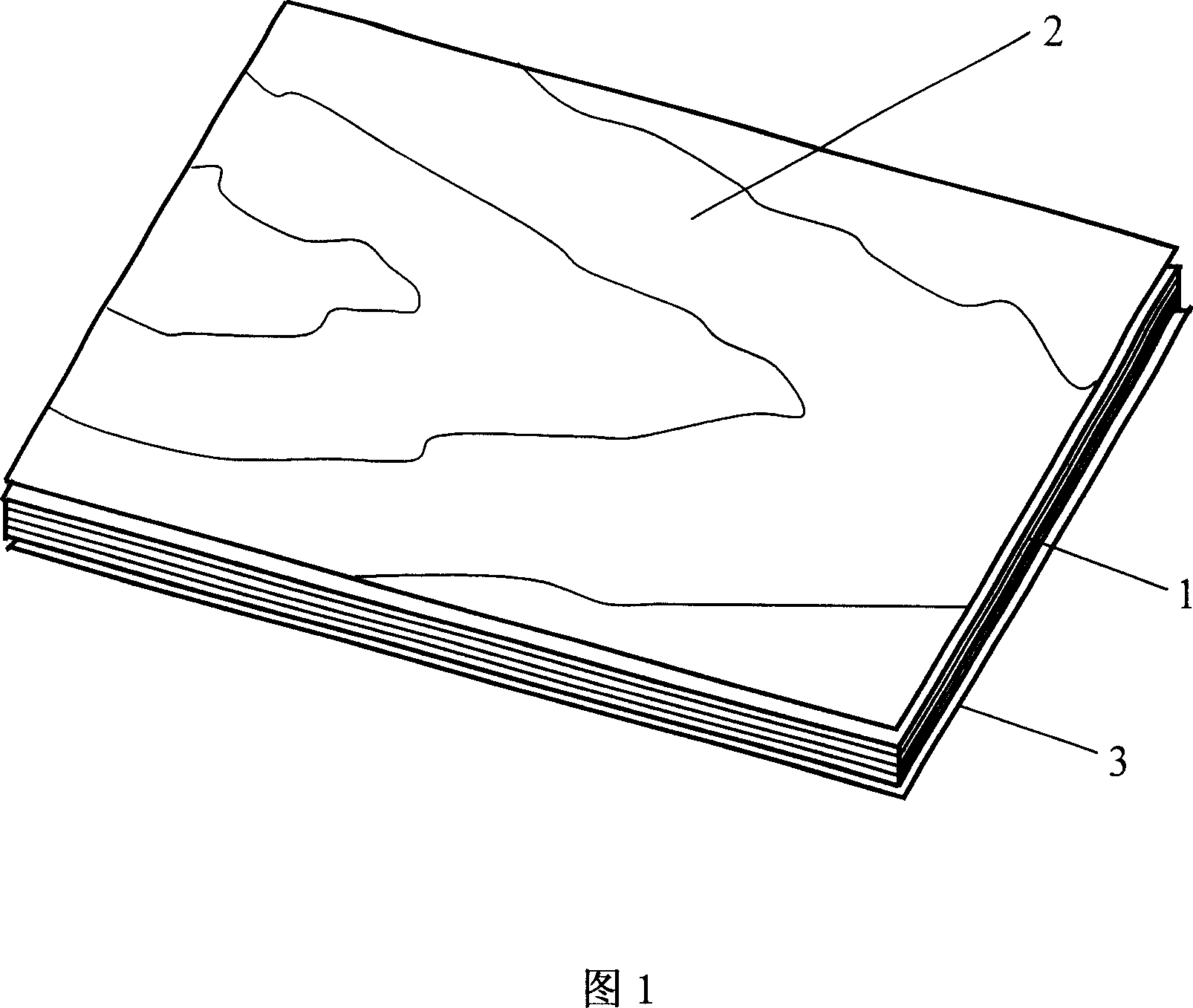

Image

Examples

Embodiment Construction

[0013] The tools and equipment used in the present invention are commonly used plywood production equipment, such as cold presses, hot presses, gluing machines, sanding machines, edge sawing machines and the like.

[0014] The material used in the present invention is the middle board, the surface board and the bottom board of any wood species, and the adhesive is vinyl acetate and isocyanate or other formaldehyde-free adhesives or formaldehyde-free rubber powder, colloidal particles and rubber strips.

[0015] The process of the present invention: first adjust the adhesive, that is, mix 10 parts of formaldehyde-free vinyl acetate and 1 part of isocyanate evenly with a mixer with a rotation speed of ≤500 rpm, and the plastic bucket cannot be a lively metal material, but Plastic bucket or stainless steel, and use up the evenly stirred adhesive within one hour, otherwise, scrap the evenly stirred adhesive. Then, process the plywood according to the following steps.

[0016] Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com