Method for controlling liquid level of pouring lip, and device

A technology of liquid level control and filling port, which is applied in the direction of liquid level control, automatic packaging control, non-electric variable control, etc., which can solve the problem of inaccurate liquid level control of filling liquid, fresh milk not meeting sterilization requirements, and affecting fresh milk products The shelf life and other issues can be solved, and the effect of realizing industrial automation and large-scale production, stable pouring liquid surface and simple structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

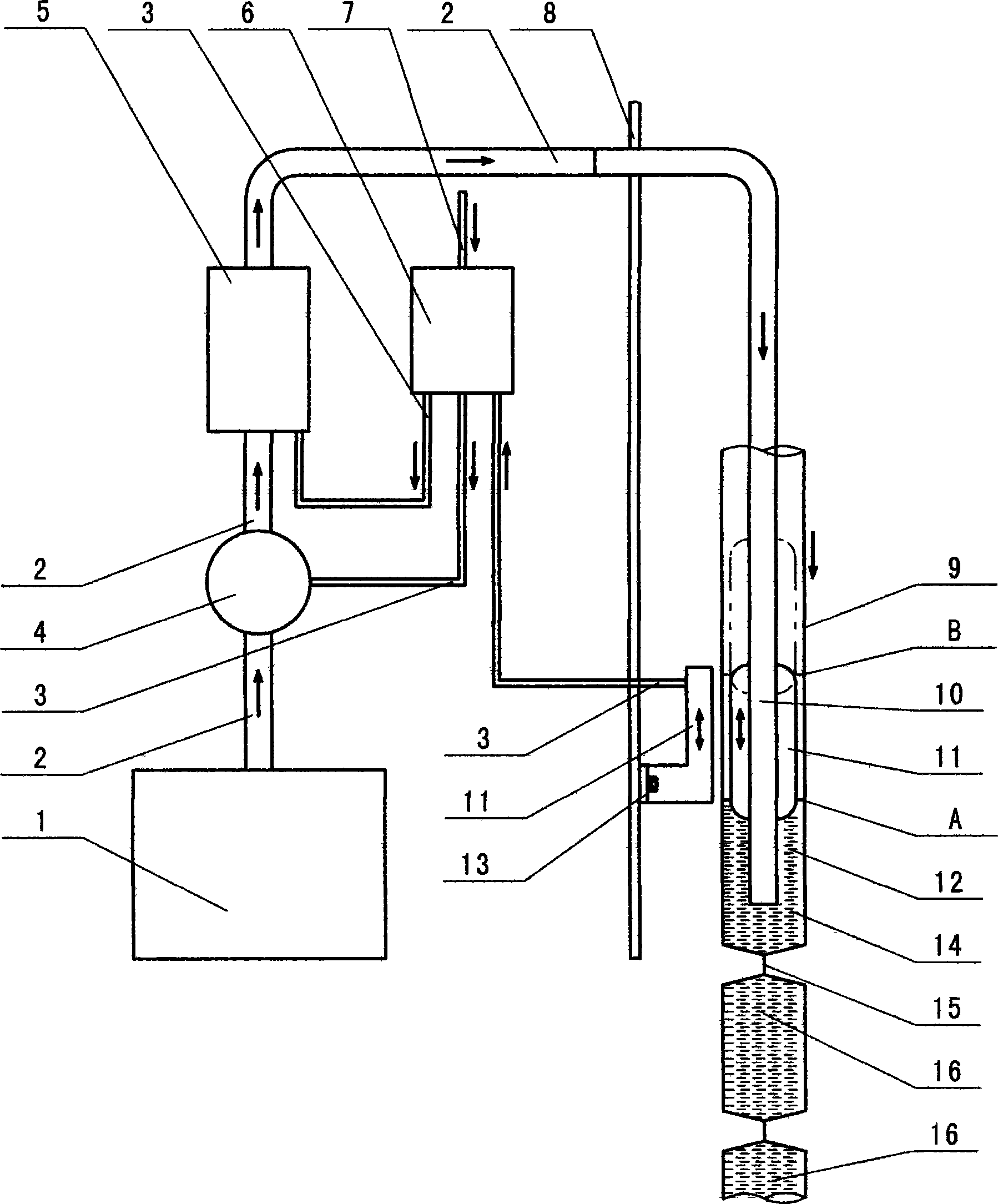

[0016] Further details will be given below with reference to the accompanying drawings: the method and device for controlling the liquid level at the filling port of a fresh milk (or other liquid food such as beverages) filling machine will be described as an example. The cylindrical packaging material 9 moves downward in the direction indicated by the arrow, and the bottom of the cylindrical packaging material 9 is sealed by a sealing device at the sealing part 15 of the packaging material. Together with the cylindrical packaging material 9, a square cylindrical packaging material 14 is formed. During the downward movement of the cylindrical packaging material 9, the upper and lower parts of the square cylindrical packaging material 14 are sealed, and the sealing part 15 of the packaging material and the square The cylindrical packaging materials 14 together form a continuous square cylindrical container 16 . One end of the filling port 10 is fixed on the fixed frame 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com