Flat knitting machine guide bar controlling device

A control device and knitting machine technology, which is applied to knitting, warp knitting, and flat warp knitting machines, and can solve problems such as difficult transportation, expensive, and heavy knitting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

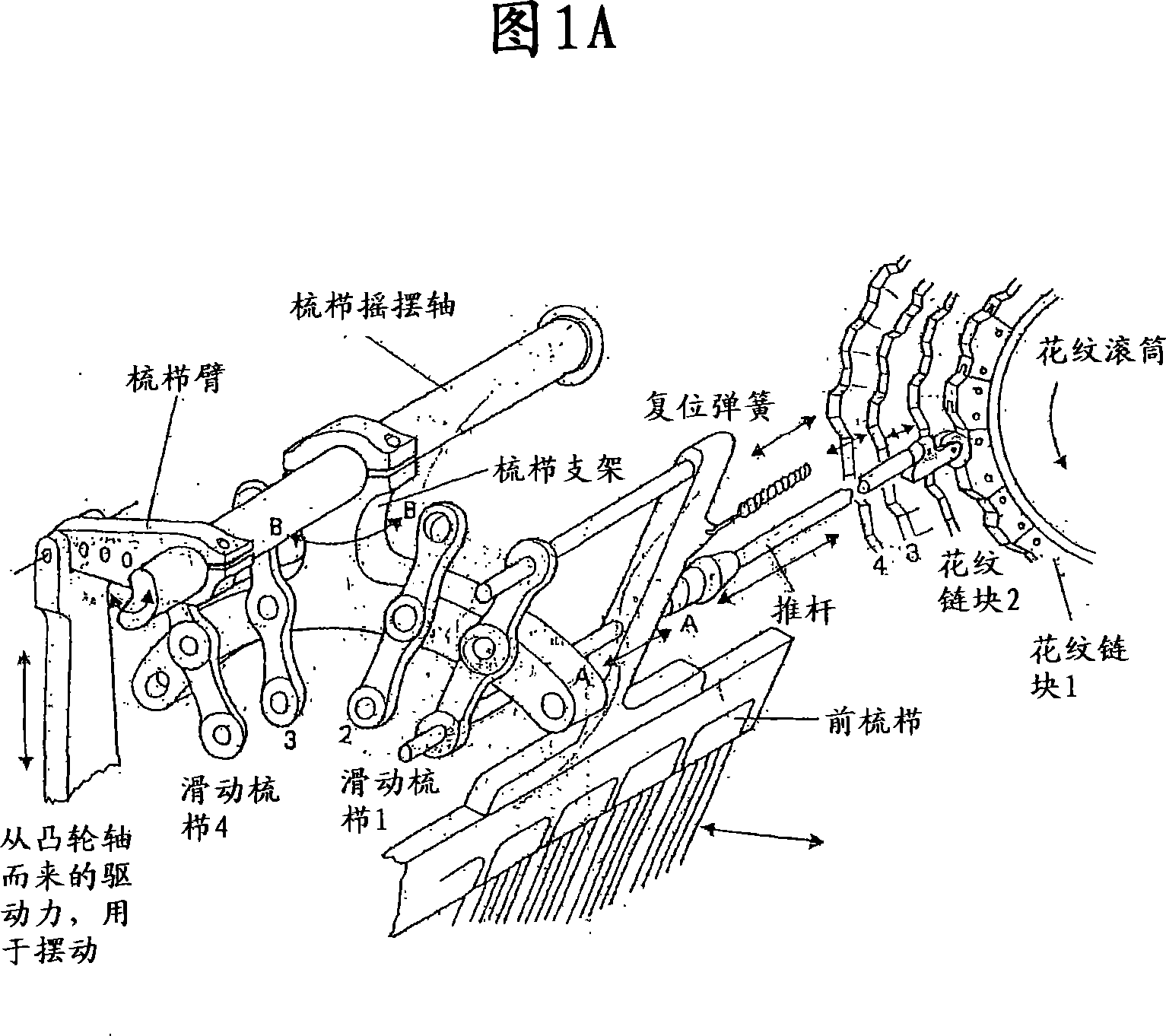

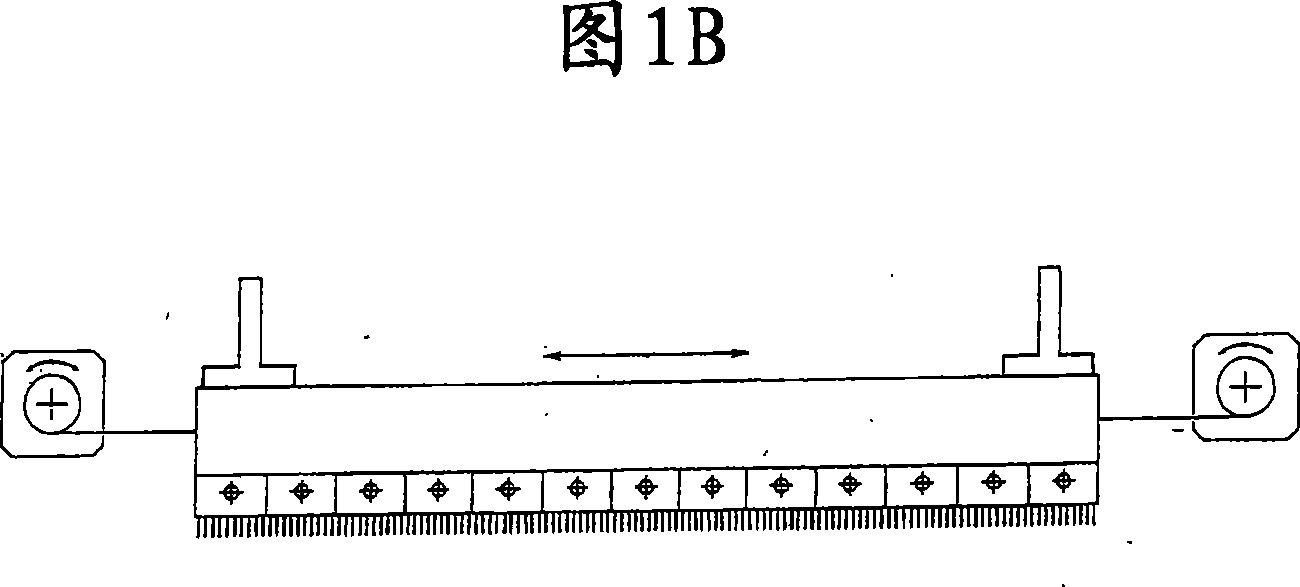

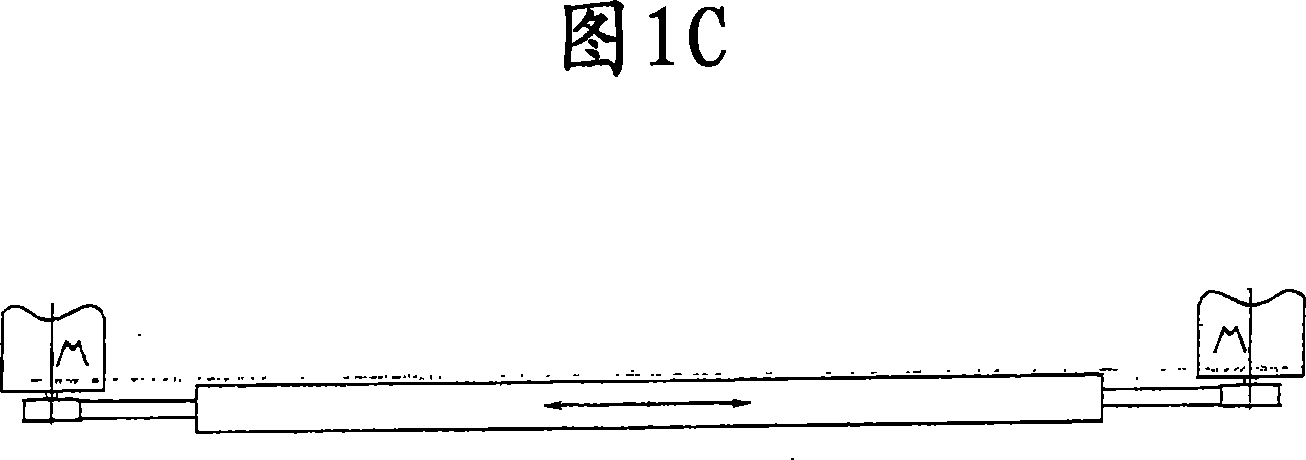

[0050] With reference to the above-mentioned accompanying drawings, the bar 2 control device 1 of the flat knitting machine in the present invention includes: a linear motor 10 for causing the bar 2 to move in translation, and a motor 10 for making the bar 2 swing substantially perpendicular to the direction of the translational movement The device 40, and the transmission device 20 that transmits the translational motion initiated by the linear motor 10 to the bar 2, so that the bar 2 can swing.

[0051] The device 1 in the present invention is characterized in that: the transmission device 20 includes a first transmission element 21 connected and integrated with the linear motor 10 , and a second transmission element 24 that can be integrally connected with the bar 2 . The first transmission element 21 also has a first guide member 22 in which the second transmission element 24 is movably connected.

[0052] The first guide 22 preferably has a substantially curved shape, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com