Glass bottle blowing process

A glass bottle and process technology, which is applied in the direction of blowing-blowing glass forming machines, etc., can solve the problems of increased scrap rate, bulging of the bottle body, and different thickness of the bottle body, so as to avoid insufficient thickness, scientific and reasonable structure, and safe and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

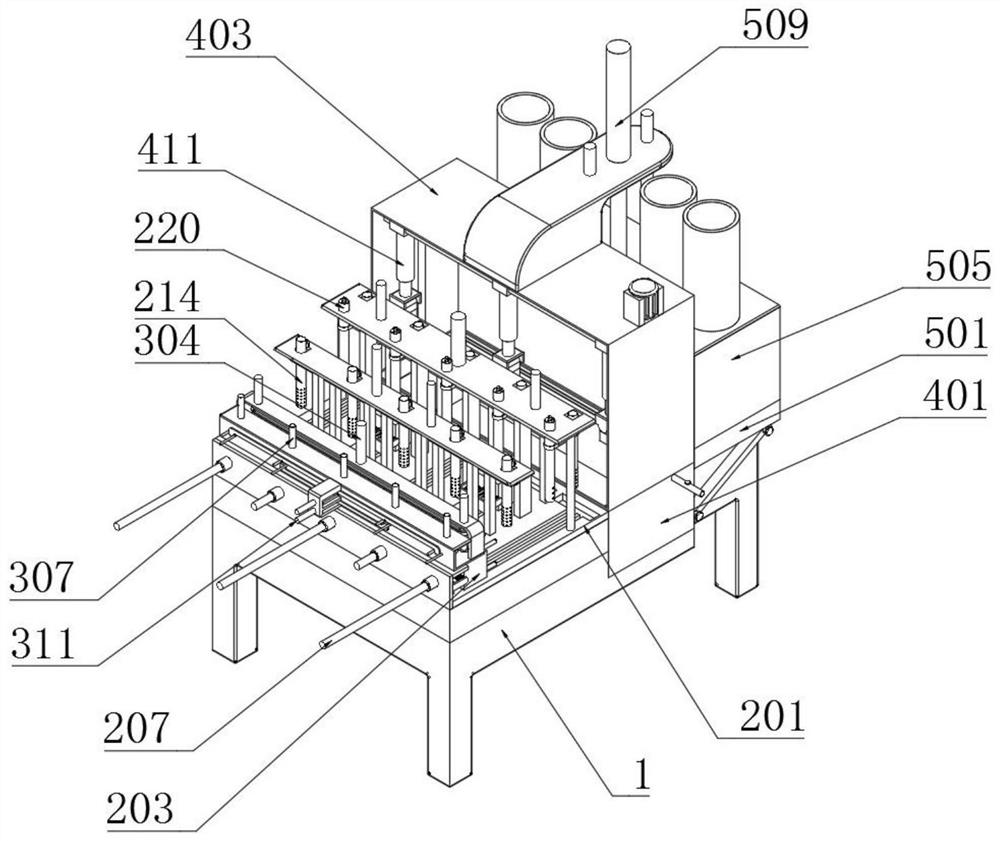

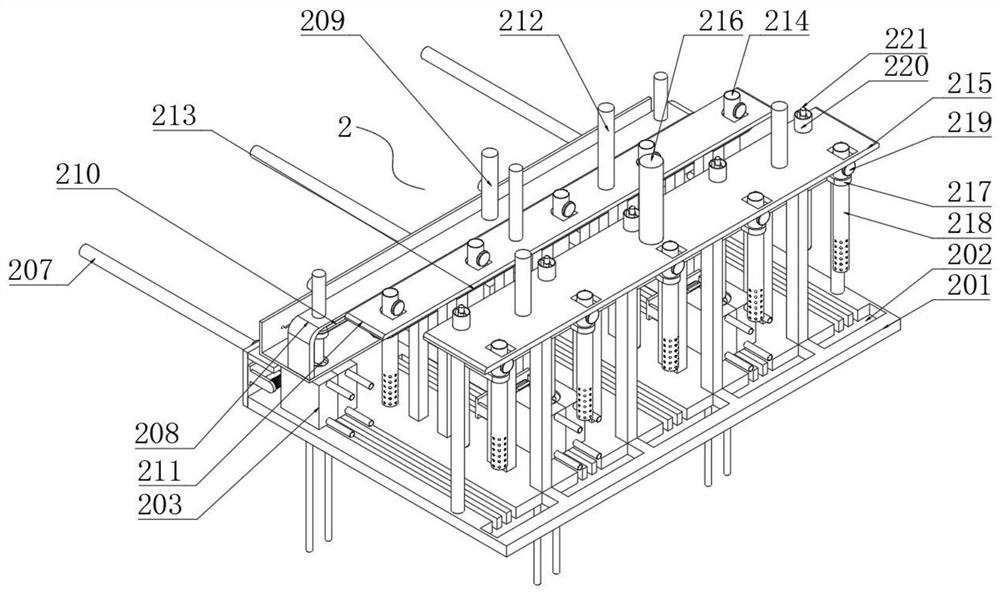

[0042] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

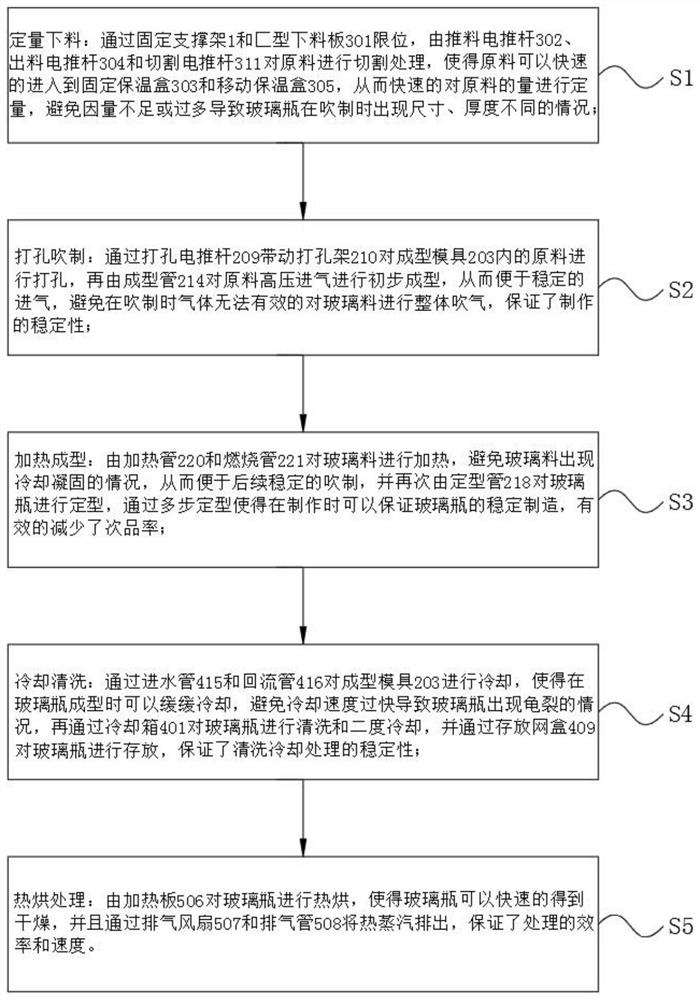

[0043] Example: such as Figure 1-14 As shown, the present invention provides a kind of technical scheme, a kind of glass bottle blowing process, comprises the steps:

[0044] S1: Quantitative blanking: through the fixed support frame 1 and the 匚-shaped blanking plate 301 to limit the position, the raw materials are cut by the pushing electric push rod 302, the discharging electric push rod 304 and the cutting electric push rod 311, so that the raw materials can be cut. Quickly enter the fixed heat preservation box 303 and the mobile heat preservation box 305, so as to quickly quantify the amount of raw materials, and avoid the situation of different sizes and thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com