Vane type electric gasoline pump body

An electric gasoline and impeller-type technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of uneven thickness of hardened layer, low qualified rate of finished products, and difficult to reach 90%, and achieve qualified finished products The effect of high efficiency, easy detection, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

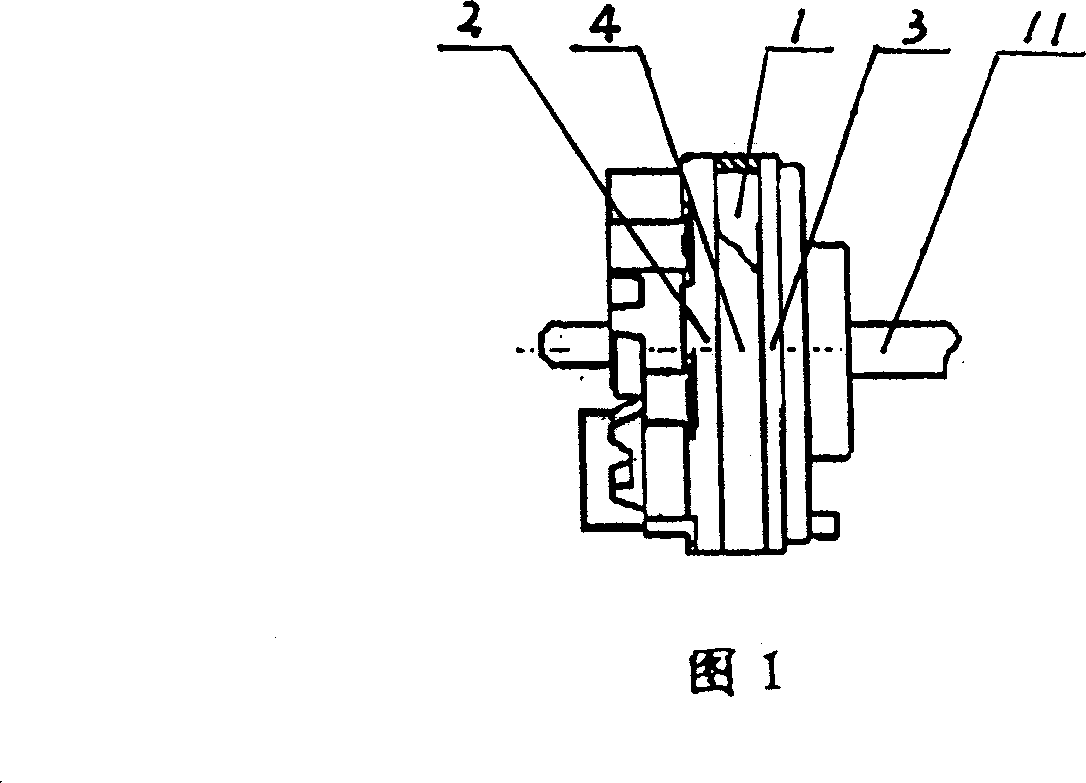

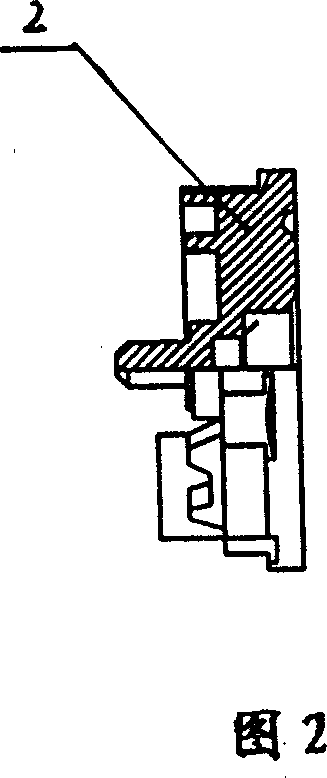

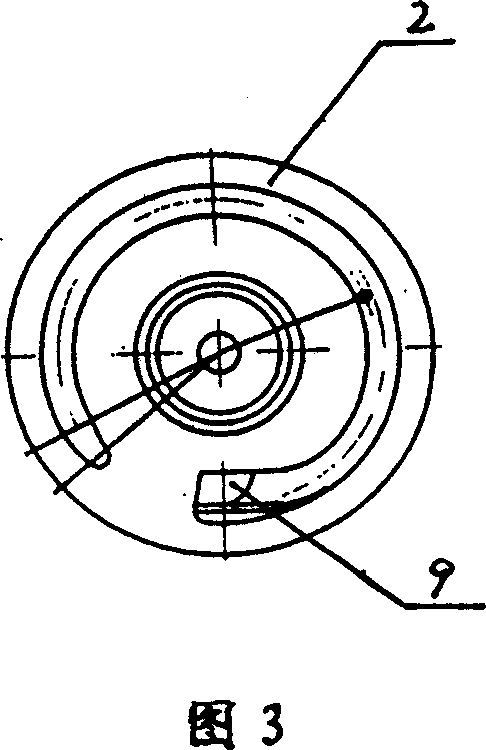

[0021] Embodiment 1: Referring to Fig. 1 to Fig. 6, the motor rotor 11 passes through the inner pump cover 3 to cooperate with the impeller 1, the collar 4 is in dynamic fit with the outer circle of the impeller 1, one end surface of which is in close contact with the edge of the inner pump cover, and the outer The edge of the pump cover 2 is in close contact with the other end surface of the impeller 1, and it only needs to be fixed together by the cylindrical casing of the electric gasoline pump during assembly. When working, the impeller in the pump body rotates at high speed driven by the motor, and the fuel enters one side of the pump body from the oil inlet hole 9 on the outer pump cover 2, and the high-speed rotating impeller 1 delivers the fuel from one side of the pump body to the side of the pump body On the other side, it is discharged from the oil hole 10 on the inner pump cover 3 .

Embodiment 2

[0022] Embodiment 2: Referring to Fig. 7 to Fig. 13, the motor rotor 11 passes through the inner pump cover 3 to cooperate with the impeller 1, and the collar 4 is movably matched with the outer circle of the impeller 1, and one end surface thereof is in close contact with the edge of the inner pump cover; The positioning pin 8 passes through the positioning through hole 5 on the collar 4, one end of the positioning pin 8 is inserted into the second positioning pin hole 7 of the inner pump cover 3, the edge of the outer pump cover 2 is in close contact with the other end surface of the impeller 1, and Insert the other end of the locating pin 8 into the first locating pin hole 6 of the outer pump cover 2; when assembling, the cylinder shell of the electric gasoline pump can be fixed together.

[0023] When working, the impeller in the pump body rotates at high speed driven by the motor, and the fuel enters one side of the pump body from the oil inlet hole 9 on the outer pump cov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap