Digital human-computer interaction system of micro beam plasma welding

A technology of micro-beam plasma and human-computer interaction, which is applied in the field of digital human-computer interaction system to achieve the effect of reducing the amount of memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

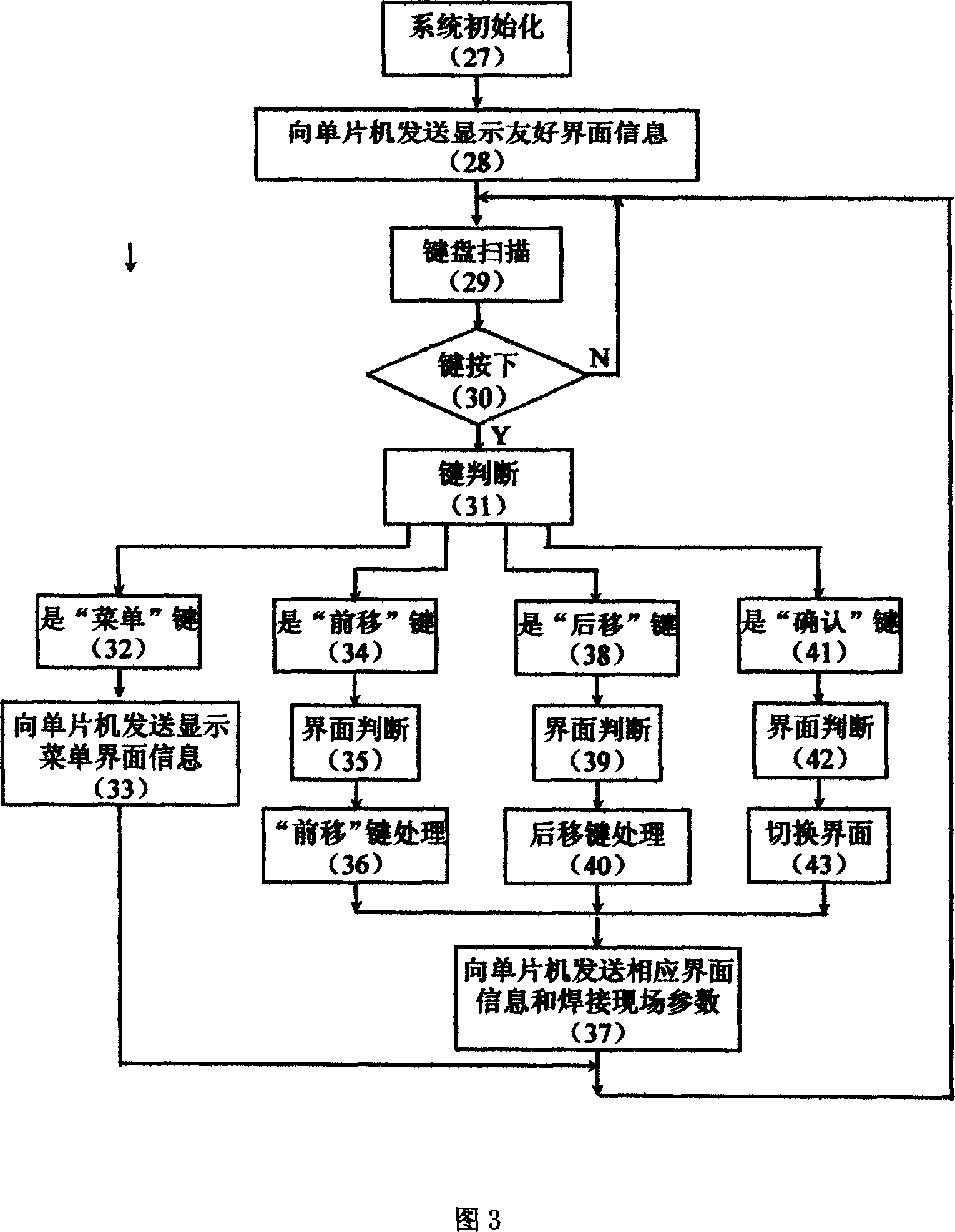

[0018] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings.

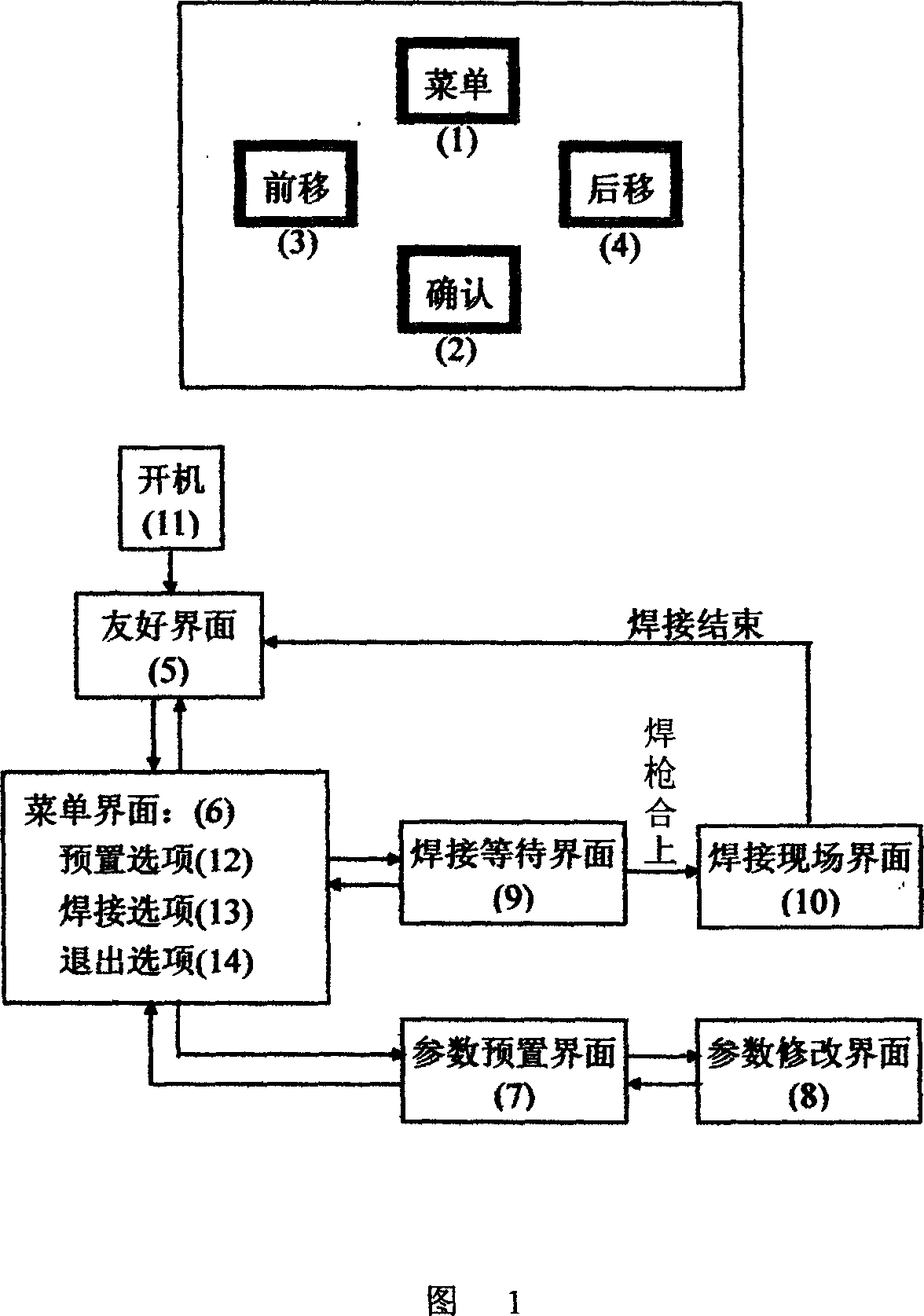

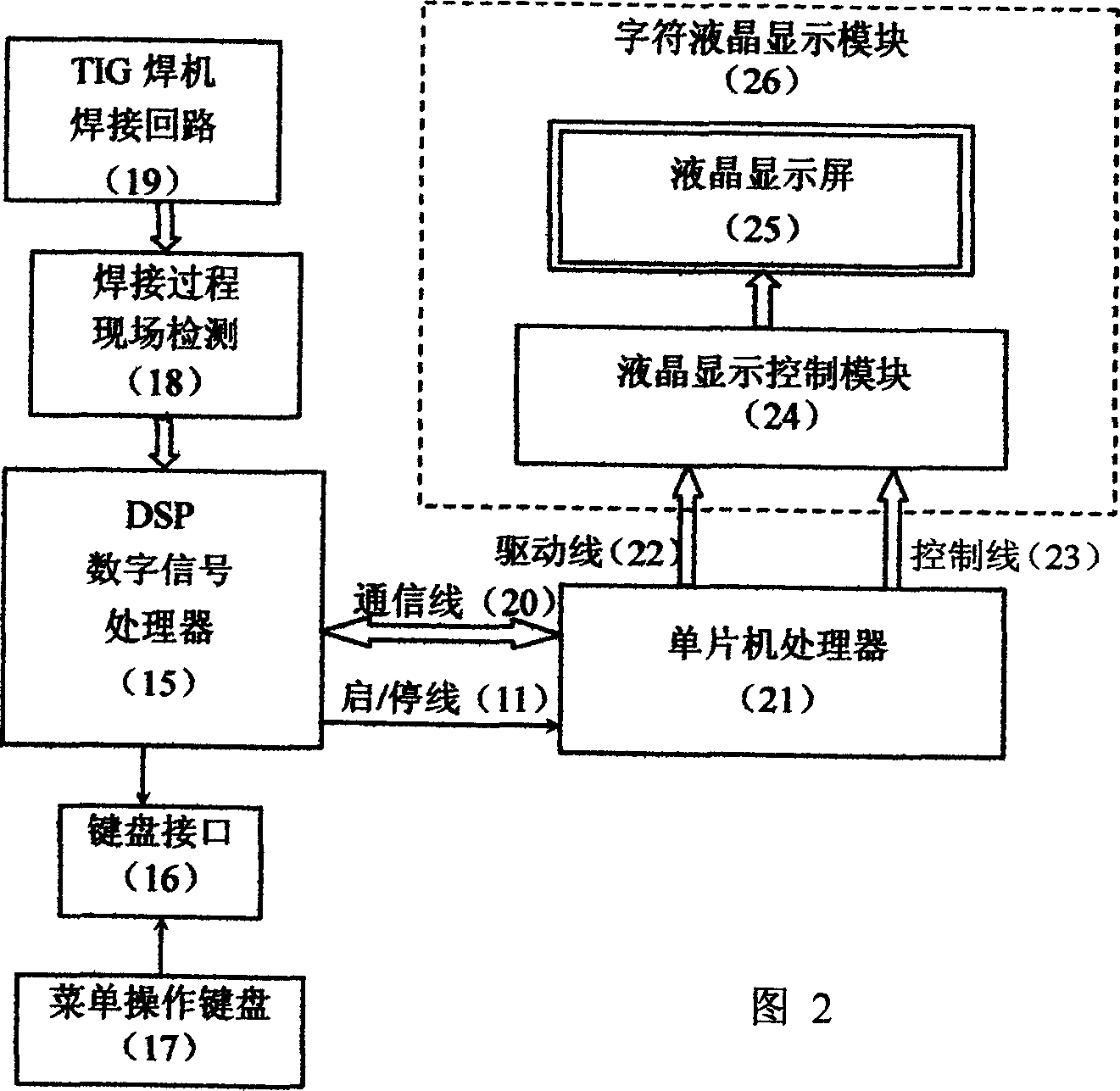

[0019]Fig. 1 is the human-computer interaction diagram of the present invention based on the micro-beam plasma welding welding process. Including "menu" 1, "confirm" 2, "forward" 3, "backward" 4 four keys and friendly interface 5, menu interface 6, parameter preset interface 7, parameter modification interface 8, welding waiting interface 9, The welding site interface 10 has six display interfaces. When starting 11, the system first displays the friendly interface 5, and monitors keyboard operations, and when the detection "menu" key 1 is pressed, the system enters the menu interface 6. According to the working process of the micro-beam plasma welding machine, there are three options in the menu interface: preset option 12, welding option 13, and exit option 14. Use the "move forward" 3 and "move backward" 4 keys to move the cursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com