Substrate check device and substrate check method

A substrate inspection and substrate technology, applied in the direction of image detector method and image signal processing, measuring device, optical device, etc., can solve the problems of difficult measurement, and achieve the effect of correctly measuring pattern defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

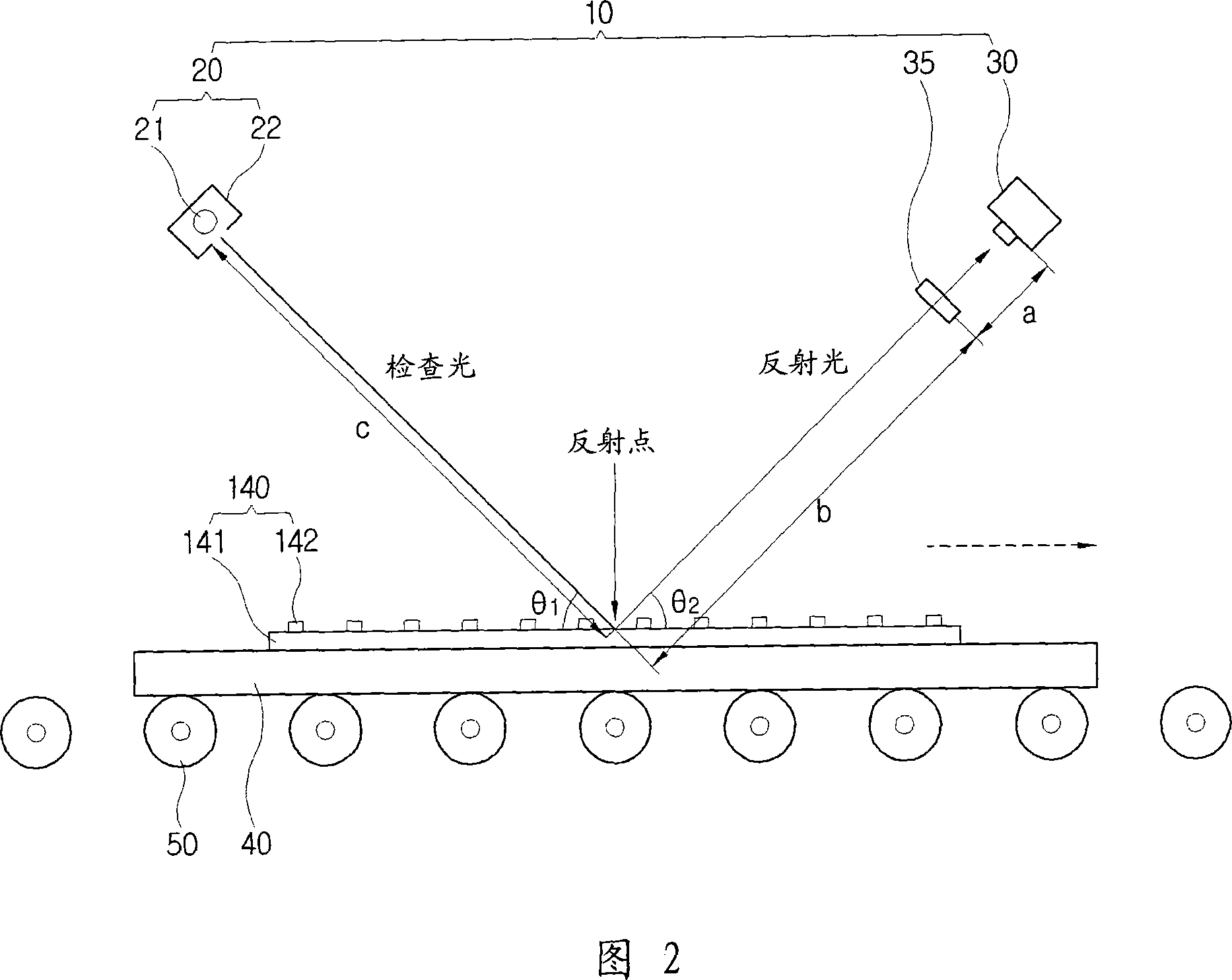

[0067] Hereinafter, the present invention will be described with reference to the accompanying drawings.

[0068] In various embodiments, the same reference numerals are attached to the same components, and the same components are typically described in the first embodiment, and may be omitted in other embodiments.

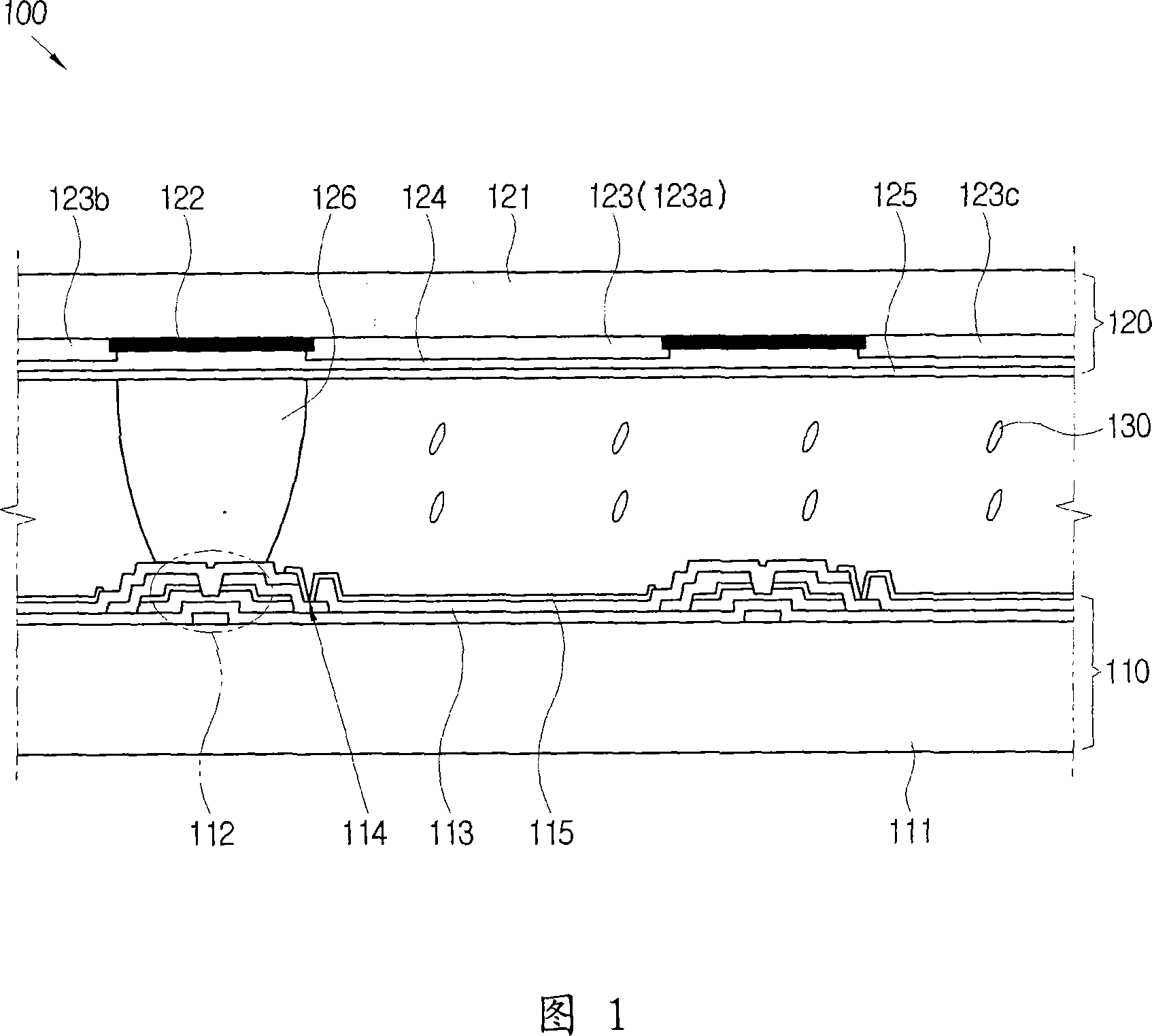

[0069] In the following embodiments, a color filter substrate of a liquid crystal display device will be described as an example of a substrate, but the present invention can also be applied to a thin film transistor substrate. In addition, the present invention can also be applied to substrates of other display devices such as organic electroluminescent devices (OLEDs), electrophoretic display devices (EPD), and plasma display devices (PDP).

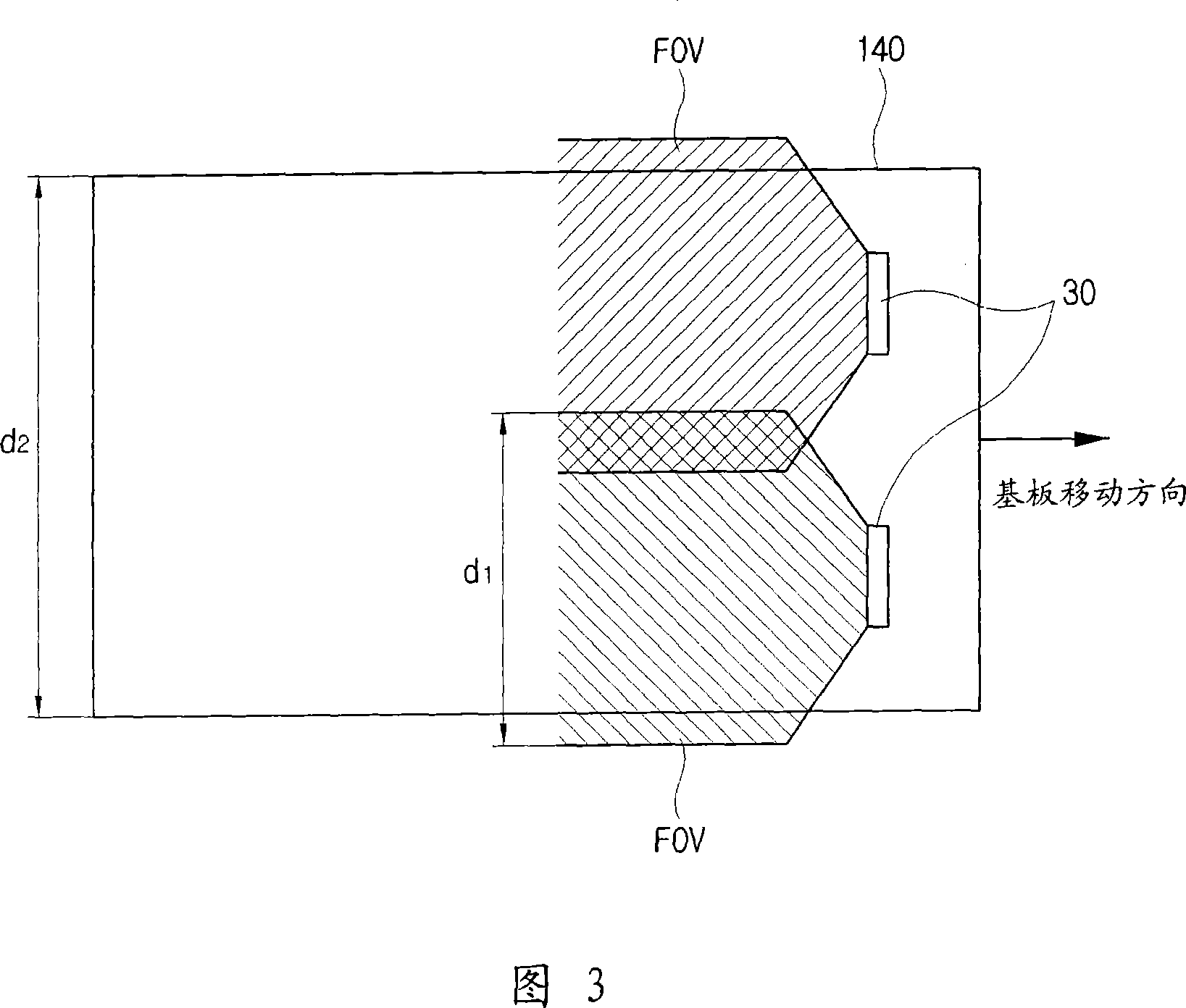

[0070] In the following description, the size of a pixel region refers to the length of one side of a square having the same area as the area of the pixel region. Each imaging unit has a square shape, and the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com