Plastic pouch and method of producing the same

A manufacturing method and technology of plastic bags, applied in bags, sacks, packaged food, etc., can solve the problems of content ejection, complicated cost, increase, etc., and achieve the effect of preventing ejection or leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

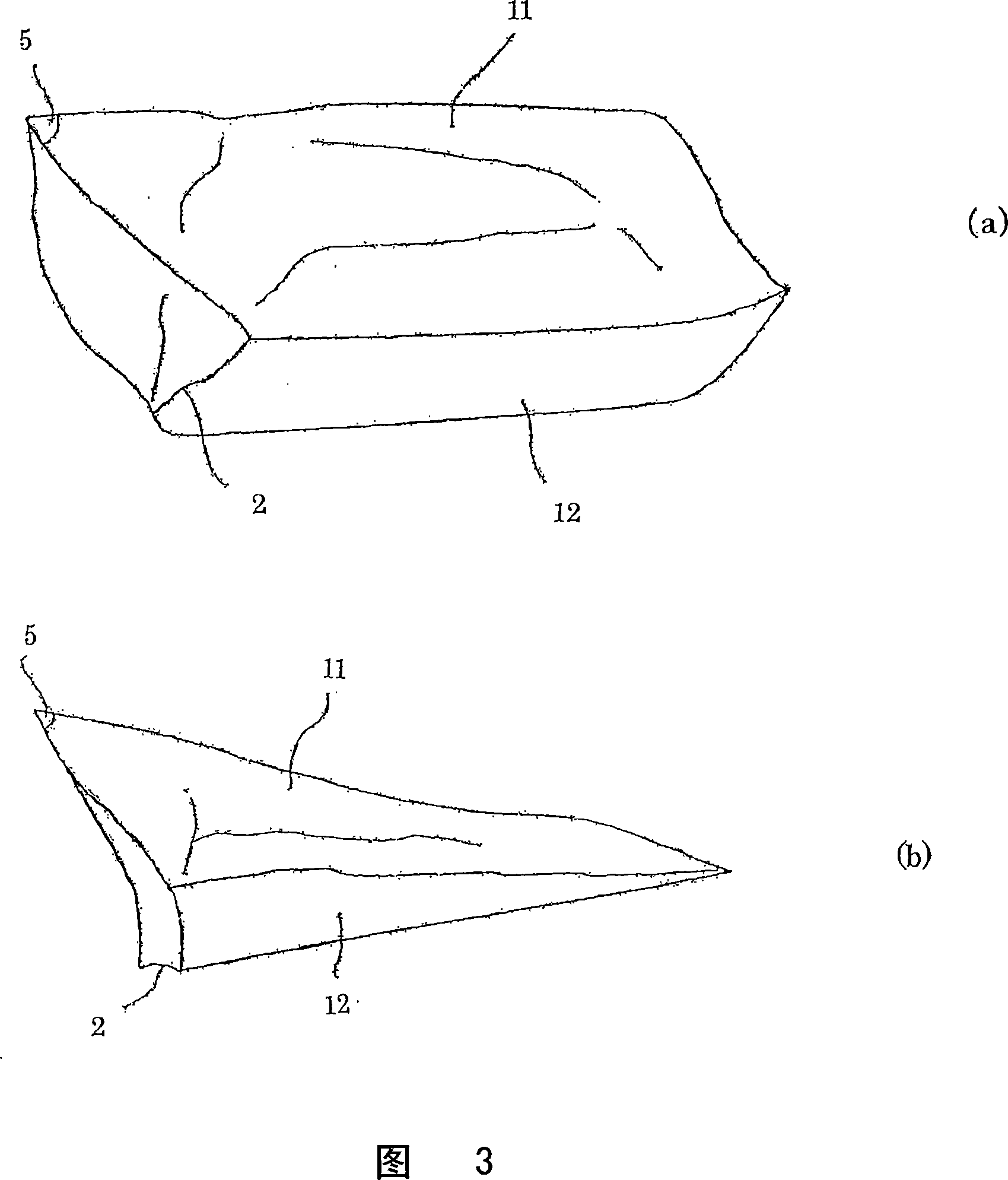

[0091] Embodiments of the present invention will be described in detail below.

[0092] As the plastic film constituting the plastic bag of the present invention, heat-sealable plastic materials generally used in the manufacture of packaging bags can be used. The plastic material includes, for example, a single-layer film or sheet containing a heat-sealable thermoplastic resin, or a multilayer film formed by laminating a heat-sealable thermoplastic resin and another thermoplastic resin.

[0093] The above-mentioned heat-sealable plastic materials include, for example, known low-density polyethylene, linear low-density polyethylene, medium-density polyethylene, high-density polyethylene, polypropylene, propylene-ethylene copolymer, ethylene-vinyl acetate copolymer, etc. olefin resins such as olefin resins grafted and modified by ethylenically unsaturated carboxylic acids and their anhydrides, polyamides and copolyamide resins with low melting point or even low softening point, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap