Three level power converter

A technology of power transformation devices and switching elements, applied in the direction of output power conversion devices, circuits, electrical components, etc., can solve problems such as difficult suppression, insufficient cooling of semiconductor components, etc., achieve balanced temperature rise, and improve cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

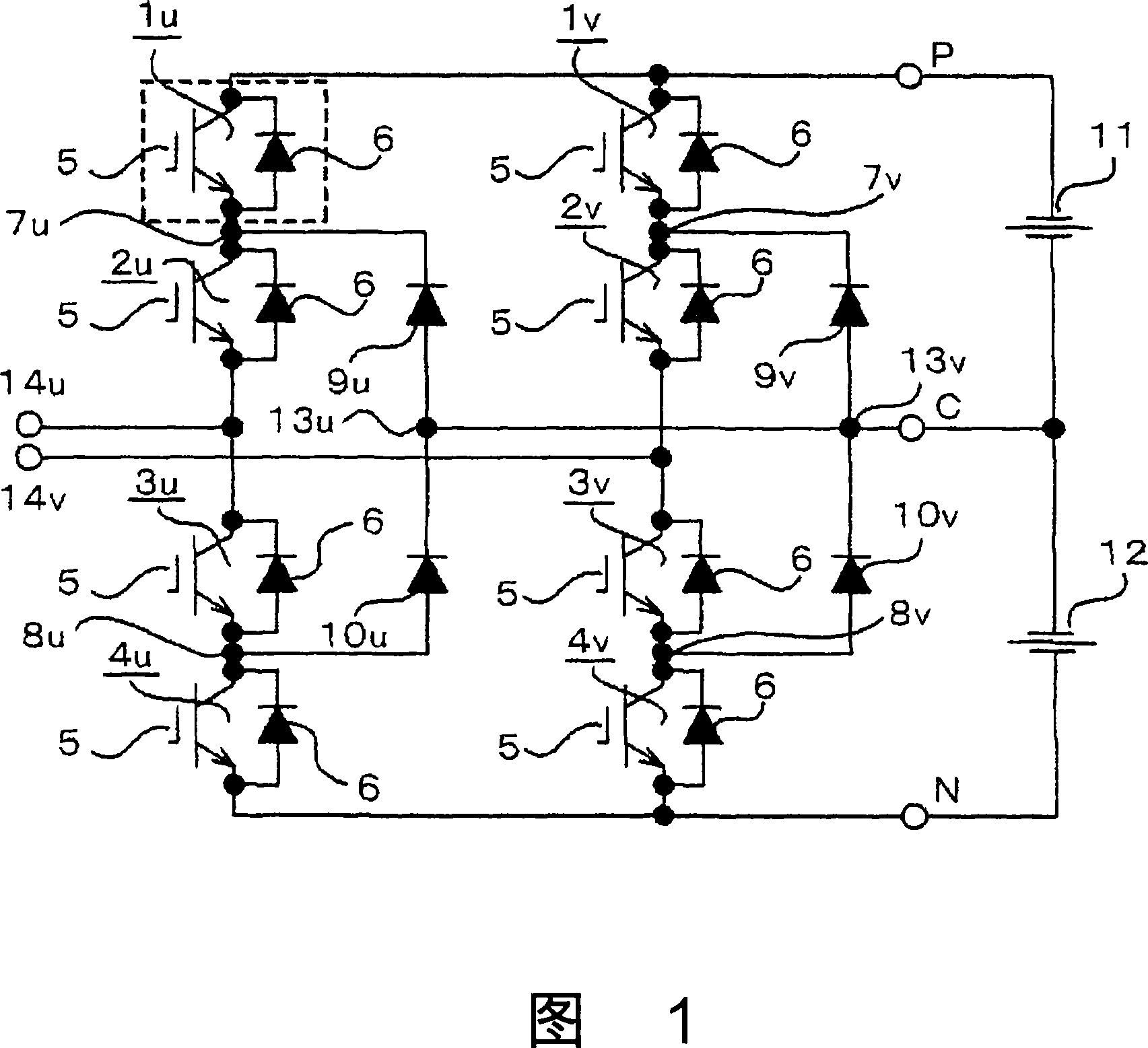

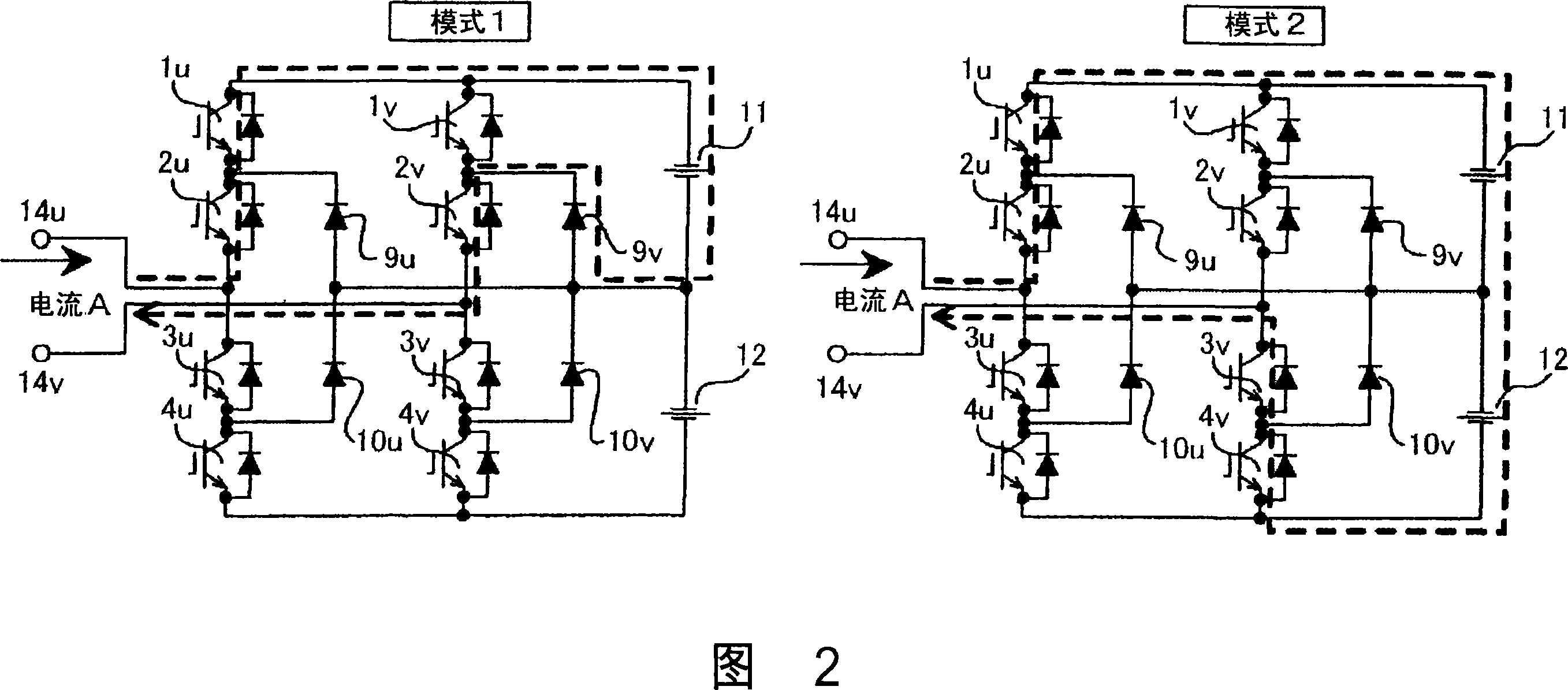

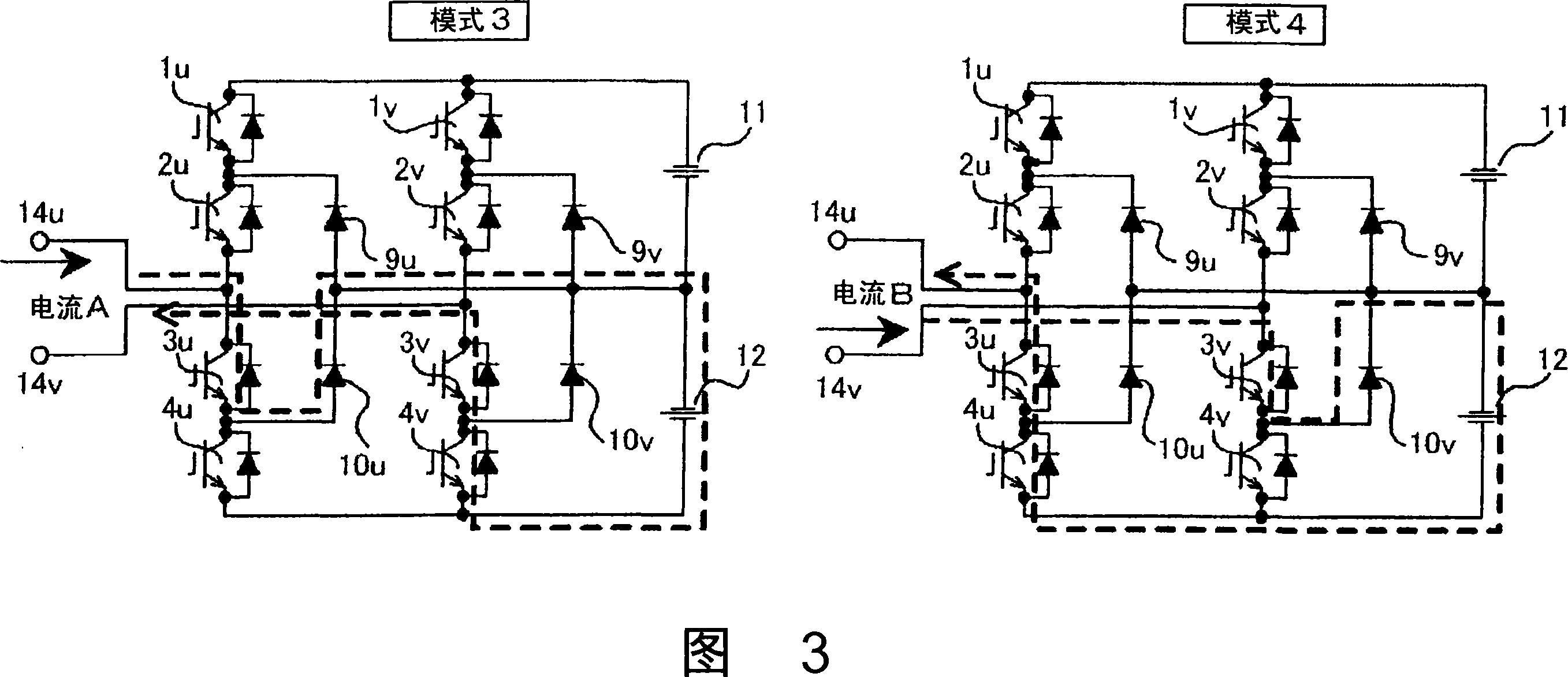

[0021] Fig. 1 is a circuit diagram using a three-level power transformer according to the present invention as a converter.

[0022] In FIG. 1 , first, the U-phase unit is sequentially connected with a first switching element 1u, a second switching element 2u, a third switching element 3u, and a fourth switching element 4u between the DC positive terminal P and the DC negative terminal N.

[0023] Similarly, in the V-phase unit, the first switching element 1v, the second switching element 2v, the third switching element 3v, and the fourth switching element 4v are sequentially connected between the DC positive terminal P and the DC negative terminal N.

[0024] Each of the switching elements 1u to 4u and 1v to 4v is composed of a self-arcing semiconductor element such as an IGBT (Insulated Gate Bipolar Transistor) or a GTO, for example. In Embodiment 1, the IGBT 5 and the freewheeling diode 6 connected in anti-parallel to the IGBT 5 are integrally modularized.

[0025] Between...

Embodiment approach 2

[0049] 9 is a plan view showing the arrangement of semiconductor elements on the cooler and the direction of cooling air in the three-stage power conversion device according to Embodiment 2 of the present invention. As in Embodiment 1 above, the configuration when used as an inverter having U-phase and V-phase inverter circuits is shown, and the circuit and operation are the same as in Embodiment 1 above.

[0050] As shown in FIG. 9 , the semiconductor element groups constituting the U-phase unit and the V-phase unit respectively are arranged on the heat receiving portion 15 of the cooler along the cooling air flow with their long sides oriented perpendicular to the cooling air flow direction. The first switching elements 1u, 1v and the fourth switching elements 4u, 4v are arranged adjacent to each other in the central portion of the heat receiving portion 15 . And, on one side of the first switching elements 1u, 1v and the fourth switching elements 4u, 4v, the second switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com