Automobile bumper forming mould forged piece

A technology for automobile bumpers and forming dies, which is applied in the field of plastic molds, can solve the problems of heavy load, poor mechanical performance, and large material waste of processing machine tools, and achieve the reduction of load weight, improvement of mold quality, and reduction of mold processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

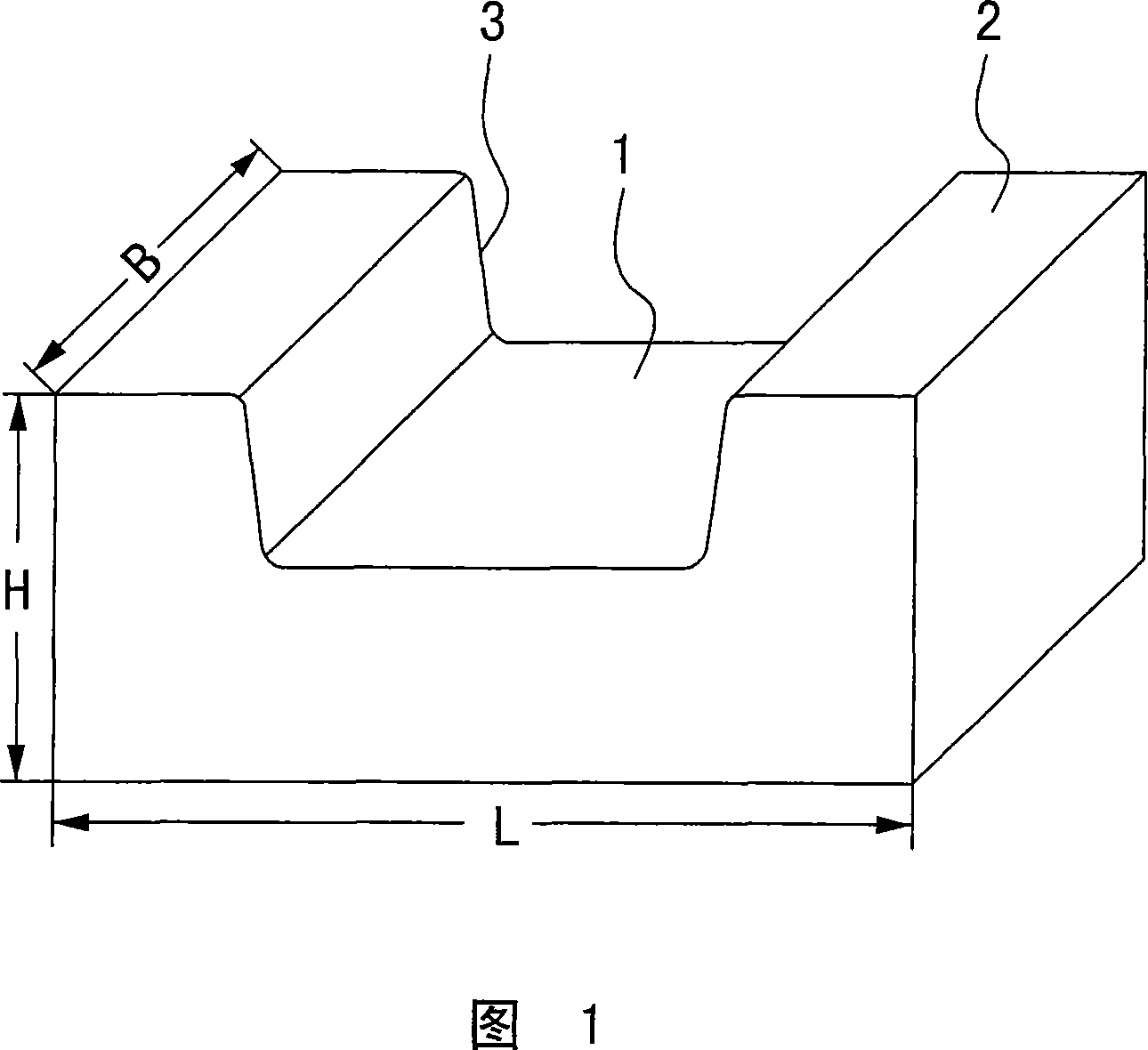

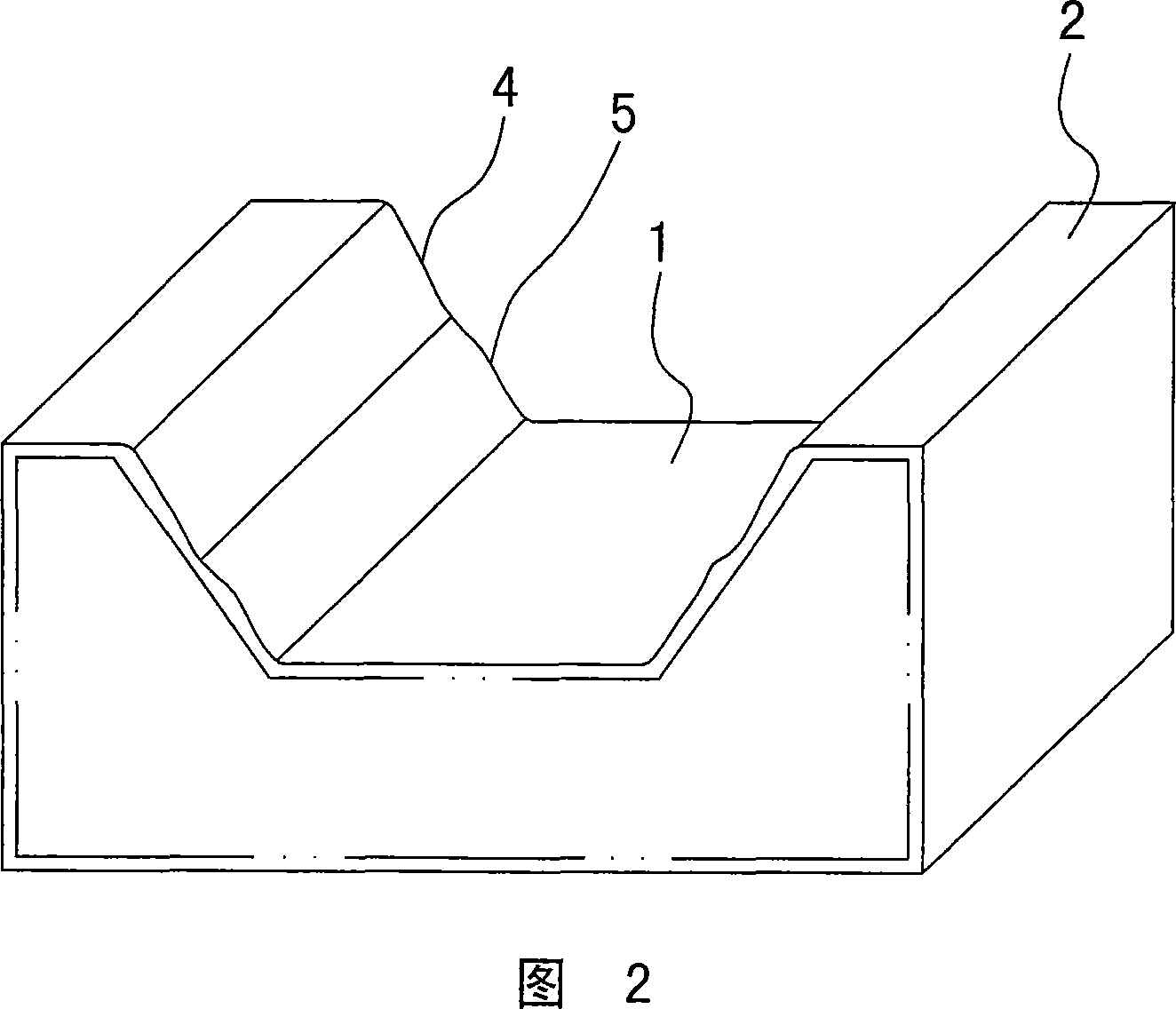

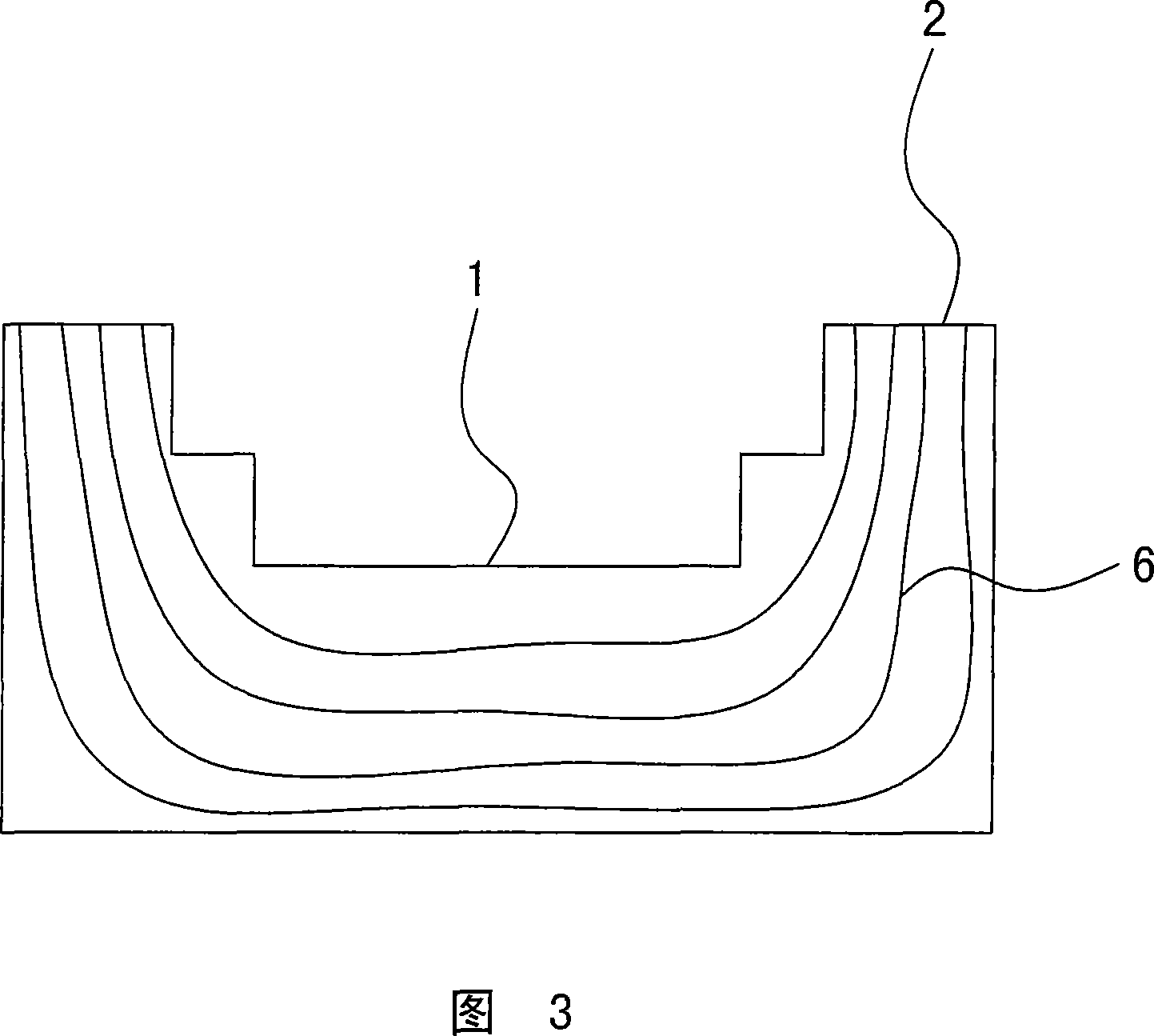

[0010] The present invention relates to automobile bumper forming die forgings, the main technical feature of which is that the forming die forgings are one side (as shown in Fig. 1 and Fig. 2 on the upper side) with a lower middle of 1 and a height of 2 at both ends, forming a concave shape. . The automobile bumper forming die forgings, when processing, take the steel ingot material, use a 1600-ton hydraulic press for upsetting-flattening-upsetting into a rectangle, and then use a chopping knife to press out two lines in the middle (the concave part) by the hydraulic press Indentation, and then the middle part is pressed down by a hydraulic press to extrude. The advantages of concave die forgings with low middle and high ends are: 1. Save cost and save processing time. The user saves more than 5,000 Kg of material for each mold, which is as much as RMB 40,000. For the same mold, the weight of the improved forging is reduced by 1 / 4 to 1 / 3 compared with that before the improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com