Steel-concrete combined beam

A concrete beam and concrete technology, applied in the field of composite beams, can solve the problems of different thermal expansion coefficients and concrete creep, etc., achieve high fatigue resistance, improve stability, and avoid the effect of beam section prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

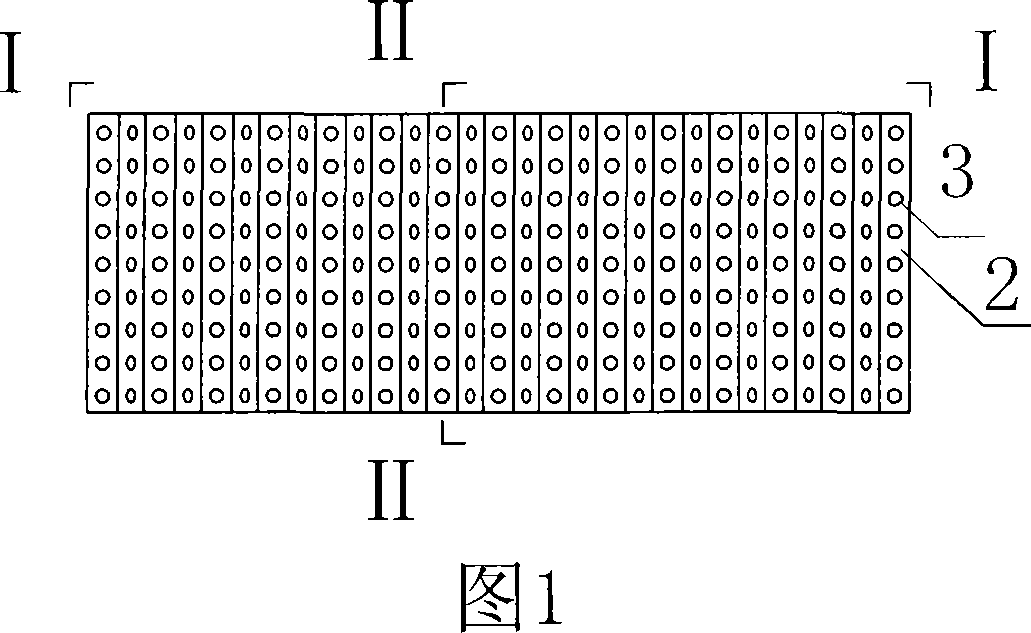

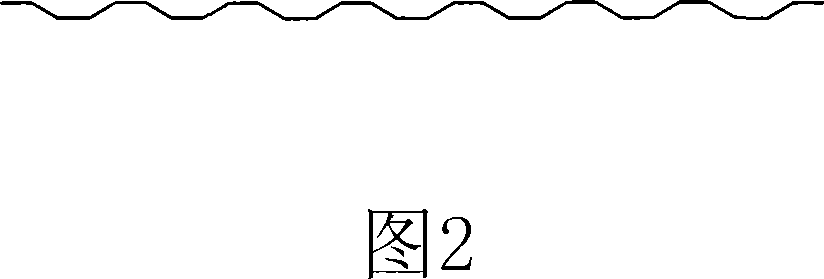

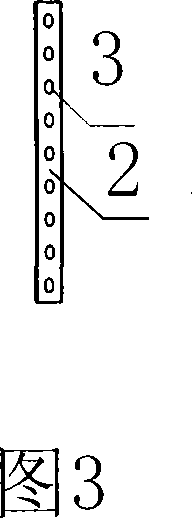

[0019] Embodiment 1 A steel-concrete composite beam, comprising a concrete beam 1, a corrugated steel plate 2 is arranged in the concrete beam 1, a hole 3 is arranged on the corrugated steel plate 2, and a stirrup is arranged in the hole 3 on the corrugated steel plate 2 5. A steel plate 6 is provided at the bottom of the corrugated steel plate 2, and a shear nail 7 is provided at the bottom of the steel plate 6.

[0020] In this embodiment, the concrete beam 1 is an I-shaped beam, and the corrugated steel plate in the steel-concrete composite beam is connected with the concrete through three kinds of shear pins: the first is that the concrete 1 fills the holes on the corrugated steel plate form a shear pin; the second is to pass the stirrup 5 through the hole of the punched corrugated steel plate 2 to form a reinforced concrete shear pin; the third is to form a punched corrugated steel plate 2 and a steel plate 6 welded with a shear nail 7 Welded together to form.

Embodiment 2

[0021] Embodiment 2 A steel-concrete composite beam, comprising a concrete beam 1, a corrugated steel plate 2 is arranged in the concrete beam 1, a hole 3 is arranged on the corrugated steel plate 2, and a stirrup is arranged in the hole 3 on the corrugated steel plate 2 5. A steel plate 6 is provided at the bottom of the corrugated steel plate 2, a shear stud 7 is provided at the bottom of the steel plate 6, and a prestressed steel bar 4 is provided in the concrete beam 1, and the prestressed steel bar 4 is located below the corrugated steel plate 2.

[0022] In this embodiment, the concrete beam 1 is a T-shaped beam, and the prestressed steel bars 4 provided in the concrete beam 1 can be arranged in a straight line, broken line or curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com