Disc type core-layer sandwich plate and its uses

A sandwich panel and core layer technology, applied in the direction of sheets/boards, building components, etc., can solve the problem of no molding production method, and achieve the effects of wide range of use, resistance to instantaneous impact loads, and strong shock absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

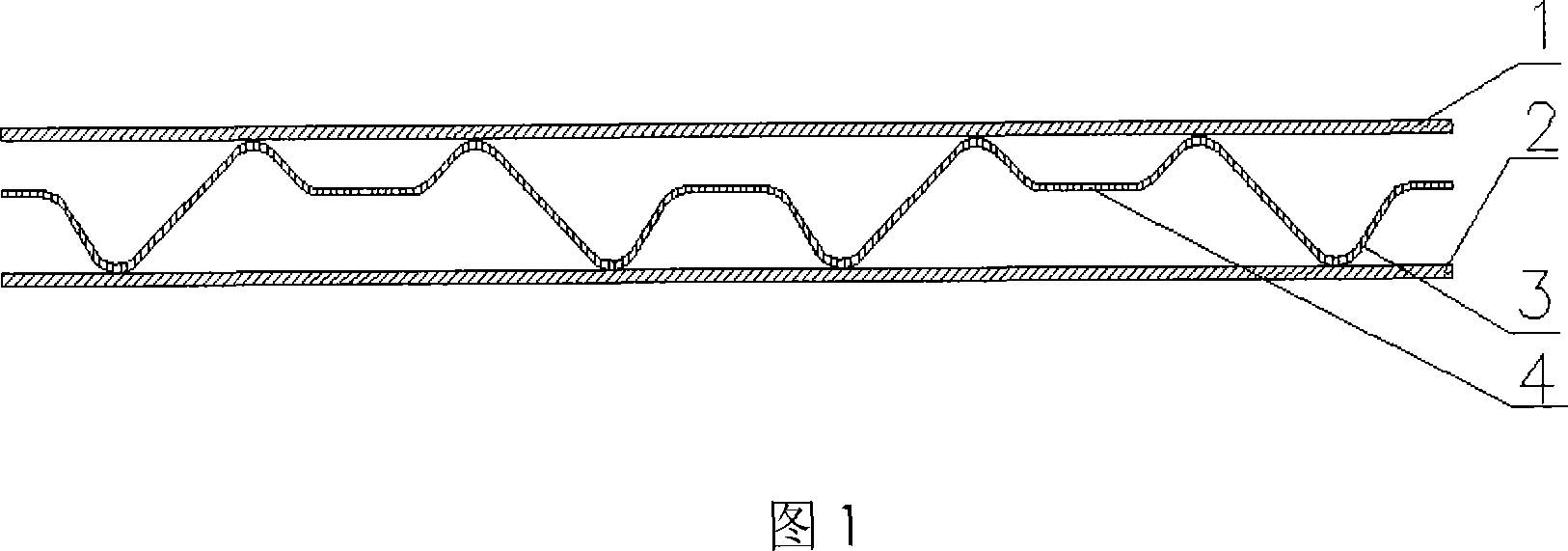

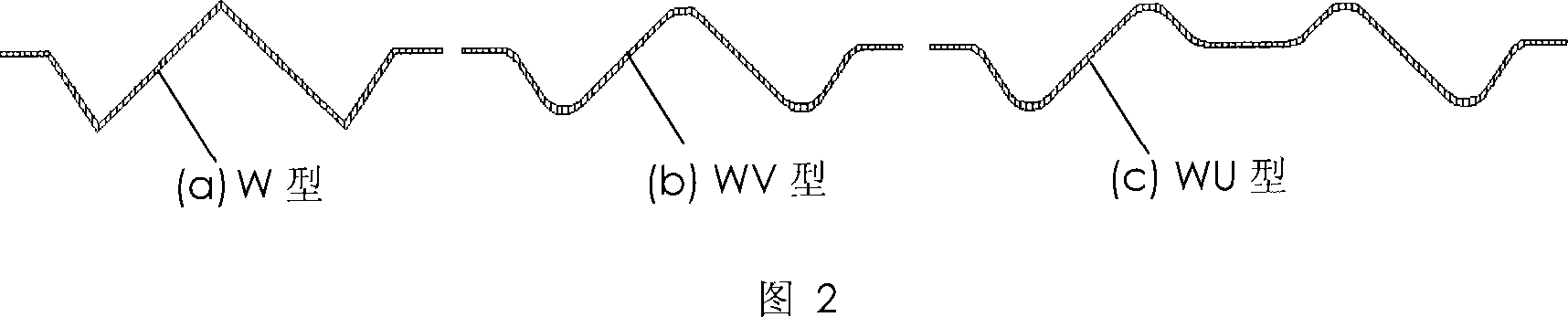

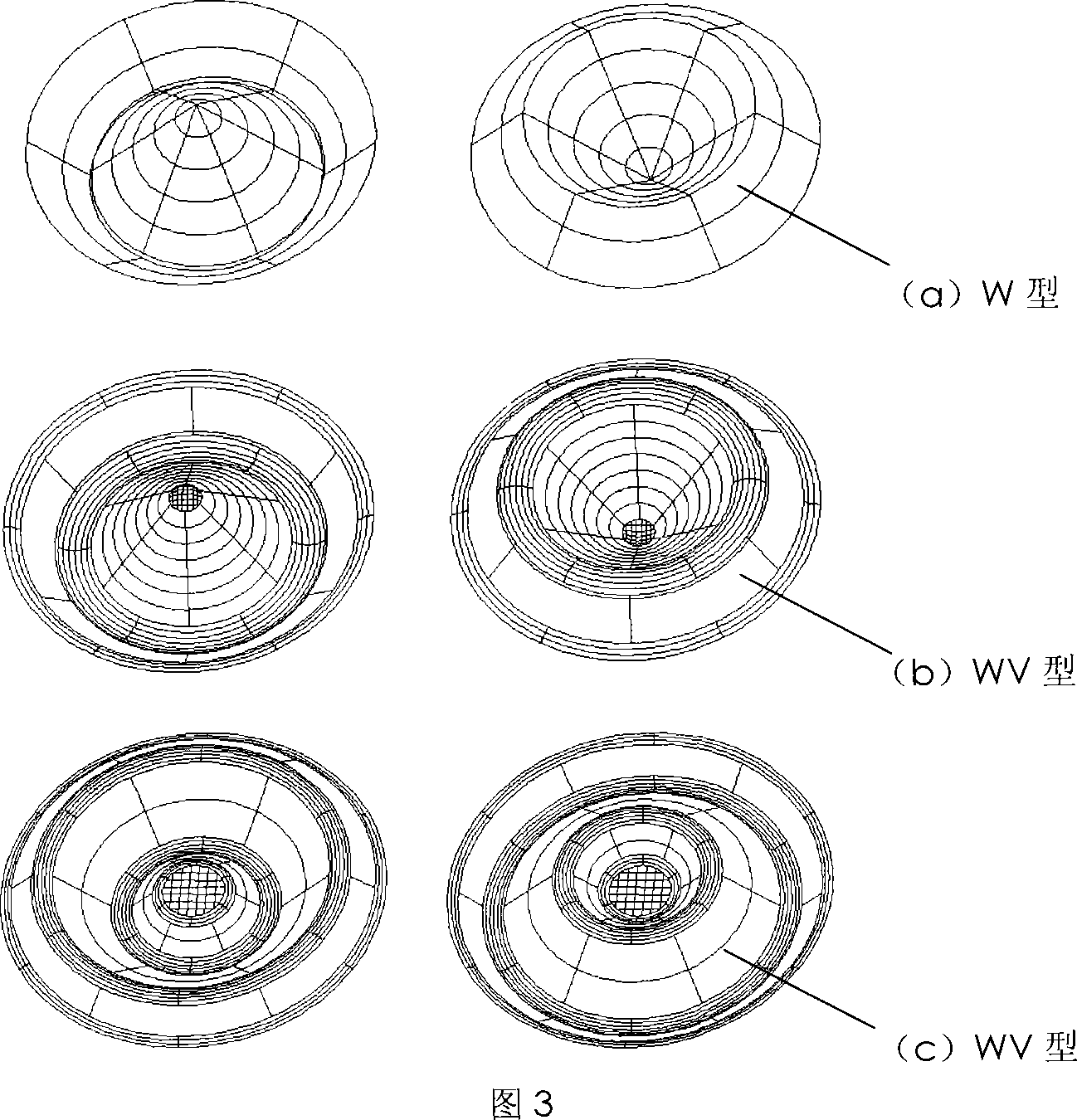

[0029] A composite plate, comprising an upper surface layer 1, a lower surface layer 2 and a core layer 3, characterized in that: the core layer 3 is a disc-shaped blister-shaped core plate, and the cross-section of the core plate is a W-shaped disc The structure of the W-shaped blister 4, the center of the frustum of the W-shaped blister 4 is pointed, and each W-shaped blister 4 forms a disc element, which protrudes up and down with the core plate surface as the center. A cone and a cone ring, as shown in Figure 2(a) and Figure 3(a). The W-shaped discs produced by calendering are parallel and symmetrically distributed on the surface of the core plate in a lattice manner to form a disc-shaped blister-shaped core plate, as shown in FIG. 7 . Other lattice distributions of butterfly elements are shown in Figure 8, Figure 9, and Figure 10. The formed composite panel structure can be a single-layer or multi-layer structure, and the directionality of the unit structure can be used ...

Embodiment 2

[0031] A composite plate, comprising an upper surface layer 1, a lower surface layer 2 and a core layer 3, characterized in that: the core layer 3 is a disc-shaped blister-shaped core plate, and the cross-section of the core plate is a WV-shaped disc The structure of the WV-shaped blister 4 is spherical, and each WV-shaped blister 4 forms a disc element, which protrudes up and down centered on the surface of the core plate. A combination of a truncated cone and a spherical crown and a combination of a truncated cone and a ring, as shown in Figure 2(b) and Figure 3(b). The WV discs produced by calendering are parallel and symmetrically distributed on the surface of the core plate in a lattice manner to form a disc-shaped blister-shaped core plate, as shown in FIG. 7 . Similarly, the dot matrix distribution of the WV dish can also adopt the manners shown in Fig. 8 , Fig. 9 and Fig. 10 . The formed composite board structure can be a single-layer or multi-layer structure, and the...

Embodiment 3

[0033]A composite plate, comprising an upper surface layer 1, a lower surface layer 2 and a core layer 3, characterized in that: the core layer 3 is a disc-shaped blister-shaped core plate, and the cross-section of the core plate is a WU-shaped disc Shaped blister 4 structure form, each WU-shaped disc-shaped blister 4 forms a disc unit, and the disc unit forms a combination of a convex conical frustum and a ring with the surface of the core plate as the center, as shown in Figure 2 (c) and Figure 3(c). The WU-shaped discs produced by calendering are parallel and symmetrically distributed on the surface of the core plate in a lattice manner to form a disc-shaped blister-shaped core plate, as shown in FIG. 7 . The upper indentation and the lower indentation of the WU-shaped dish-shaped blister 4 form two closed airbag structures with the upper surface layer 1 and the lower surface layer 2 respectively. Similarly, the dot matrix distribution of the WU-shaped dish can also be in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com