A method for improving the carbinol-resisting infiltration of fluorine-containing sulfonic acid proton exchange film

A technology of proton exchange membrane and fluorine-containing sulfonic acid, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems such as difficult control of quantity and shape, and achieve reduced methanol permeability, good electrical conductivity, The effect of improving the resistance to methanol penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Perfluorosulfonic acid type proton exchange membrane Nafion 117 anti-methanol penetration treatment

[0028] 1) The perfluorosulfonic acid type proton exchange membrane Nafion 117 film (produced by DuPont, USA, with a film thickness of about 178 microns and a molar mass of 1100) placed in 5wt% H 2 o 2 , 1mol / L of H 2 SO 4 and deionized water for 30 minutes each to obtain the pretreated perfluorosulfonic acid proton exchange membrane Nafion 117;

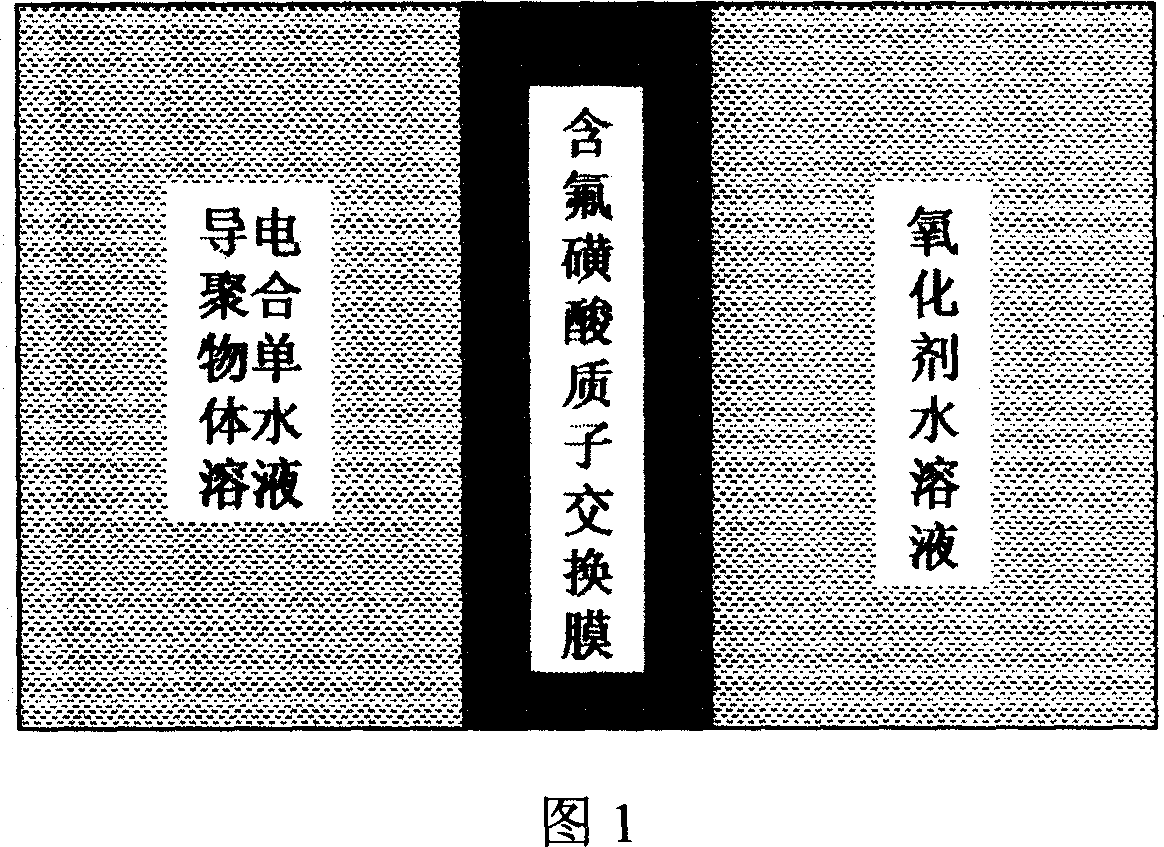

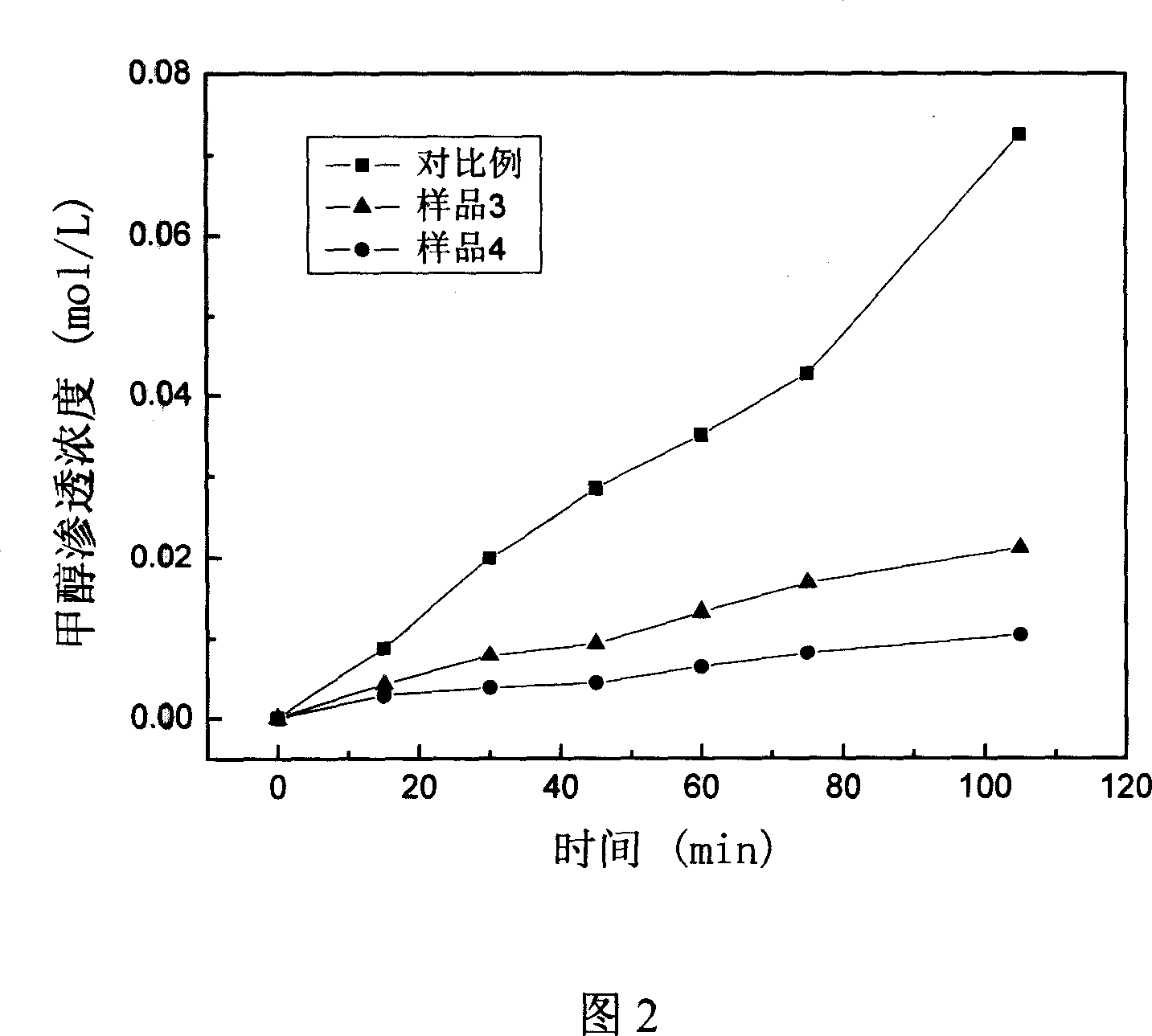

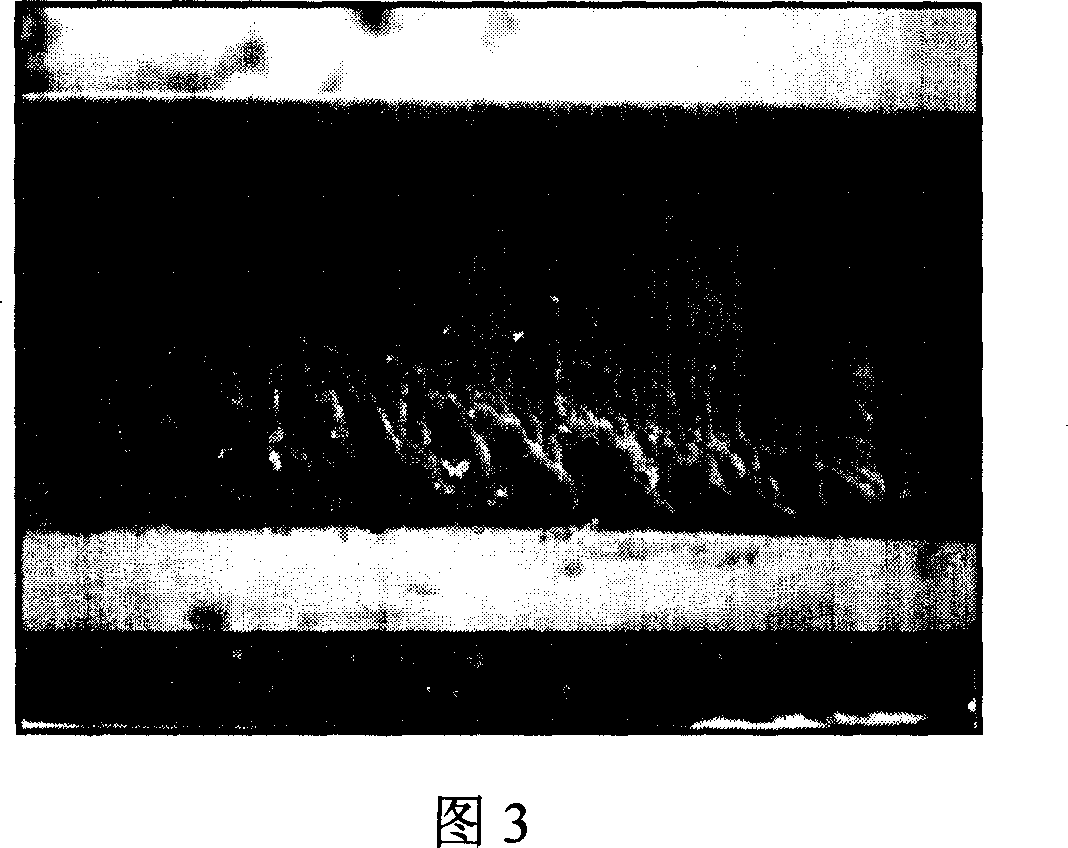

[0029] 2) The pretreated perfluorosulfonic acid proton exchange membrane Nafion 117 is placed in the middle of the diffusion cell, one side is an aqueous solution of pyrrole monomer with a concentration of 0.1mol / L, and the other side is FeCl with a concentration of 0.5mol / L 3 Aqueous solution, after polymerization at 25°C for 1, 3, 5, 10, and 15 hours, then take out H at 1mol / L in sequence 2 SO 4 Soak in deionized water for 30 minutes each to obtain Nafion, a perfluorosulfonic acid proton exchange m...

Embodiment 2

[0033] Example 2: Perfluorosulfonic acid-type proton exchange membrane Nafion 112 anti-methanol penetration treatment

[0034] 1) The perfluorosulfonic acid type proton exchange membrane Nafion 112 (produced by U.S. DuPont company, film thickness is about 50 microns, molar mass 1100) placed in 5wt% H 2 o 2 , 1mol / L of H 2 SO 4 and deionized water for 30 minutes each to obtain the pretreated perfluorosulfonic acid proton exchange membrane Nafion 112;

[0035] 2) The pretreated perfluorosulfonic acid proton exchange membrane Nafion 112 is placed in the middle of the diffusion cell, one side is an aqueous solution of pyrrole monomer with a concentration of 1mol / L, and the other side is H with a concentration of 1mol / L 2 o 2 Aqueous solution, after polymerization at 25°C for 5, 10, 15, and 20 hours, then take out H at 1mol / L in sequence 2 SO 4 Soak in deionized water for 30 minutes each to obtain Nafion, a perfluorosulfonic acid proton exchange membrane resistant...

Embodiment 3

[0038] Example 3: Anti-methanol permeation treatment of perfluorosulfonic acid type proton exchange membrane CHFM10125

[0039] 1) Place the perfluorosulfonic acid type proton exchange membrane CHFM10125 (produced by Shandong Dongyue Group, with a membrane thickness of about 125 microns and a molar mass of 1000) in 5 wt% H 2 o 2 , 1mol / L of H 2 SO 4 and deionized water for 30 minutes each to obtain a pretreated perfluorosulfonic acid proton exchange membrane CHFM10125;

[0040] 2) Place the pretreated perfluorosulfonic acid proton exchange membrane CHFM10125 in the middle of the diffusion cell, one side is an aqueous solution of thiophene monomer with a concentration of 0.008mol / L, and the other side is Na with a concentration of 2mol / L 2 S 2 o 8 Aqueous solution, after polymerization at 60°C for 5, 10, 15, and 20 hours, then take out H at 1mol / L in sequence 2 SO 4 and deionized water respectively soaked for 30 minutes to obtain perfluorosulfonic acid type proton exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap