Curved laminated glass for vehicle and vehicle fixed with the curved laminated glass

A laminated glass, bending technology, applied in glass/slag layered products, vehicle parts, windshields, etc., can solve problems such as increased cost, damage to the appearance of window glass, and less obvious effect of natural vibration of glass, and achieves improvement. Comfort, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

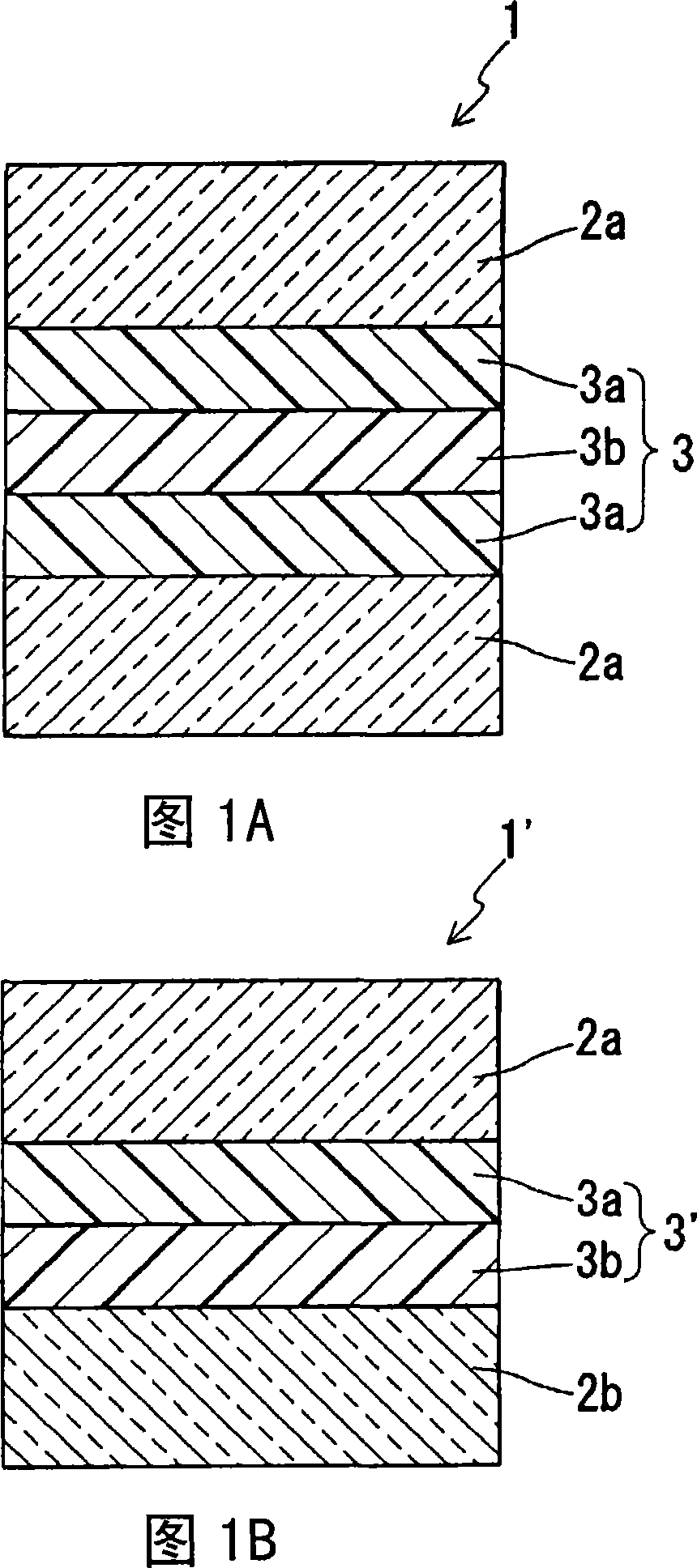

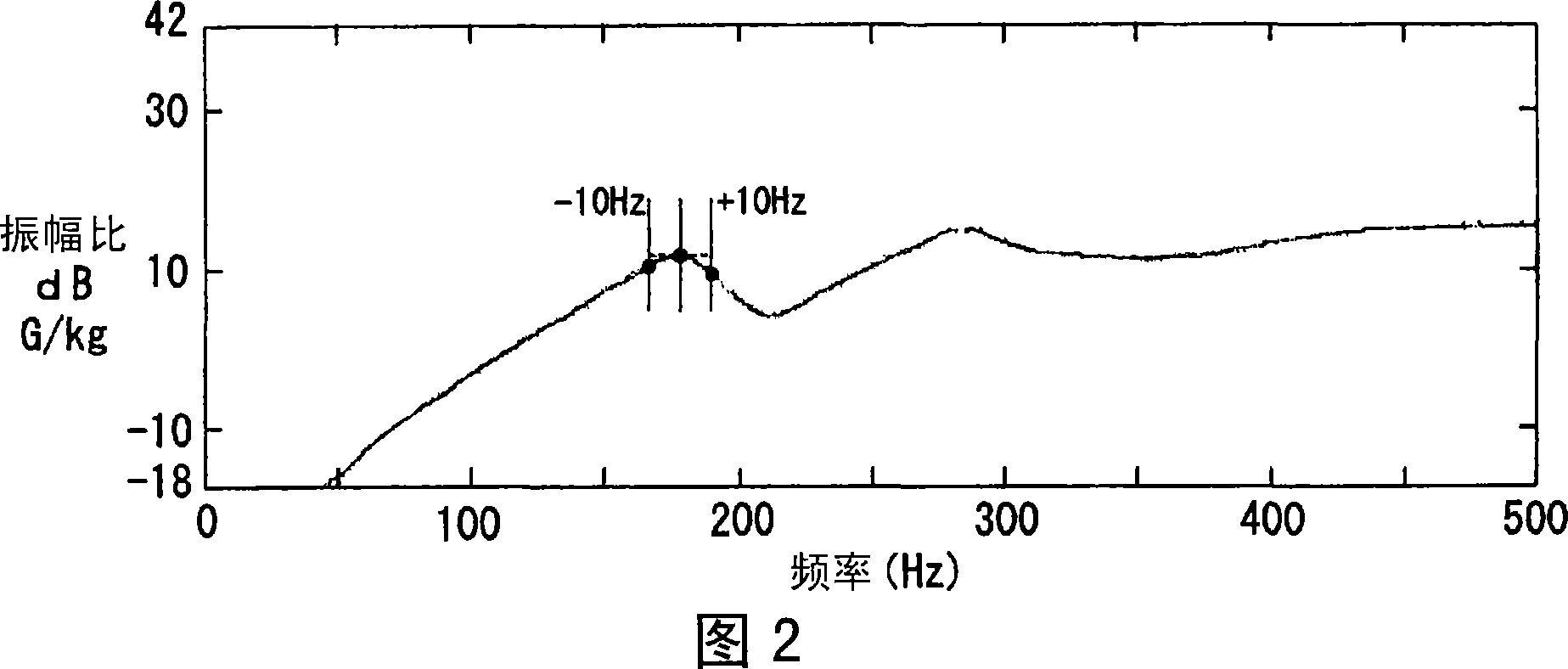

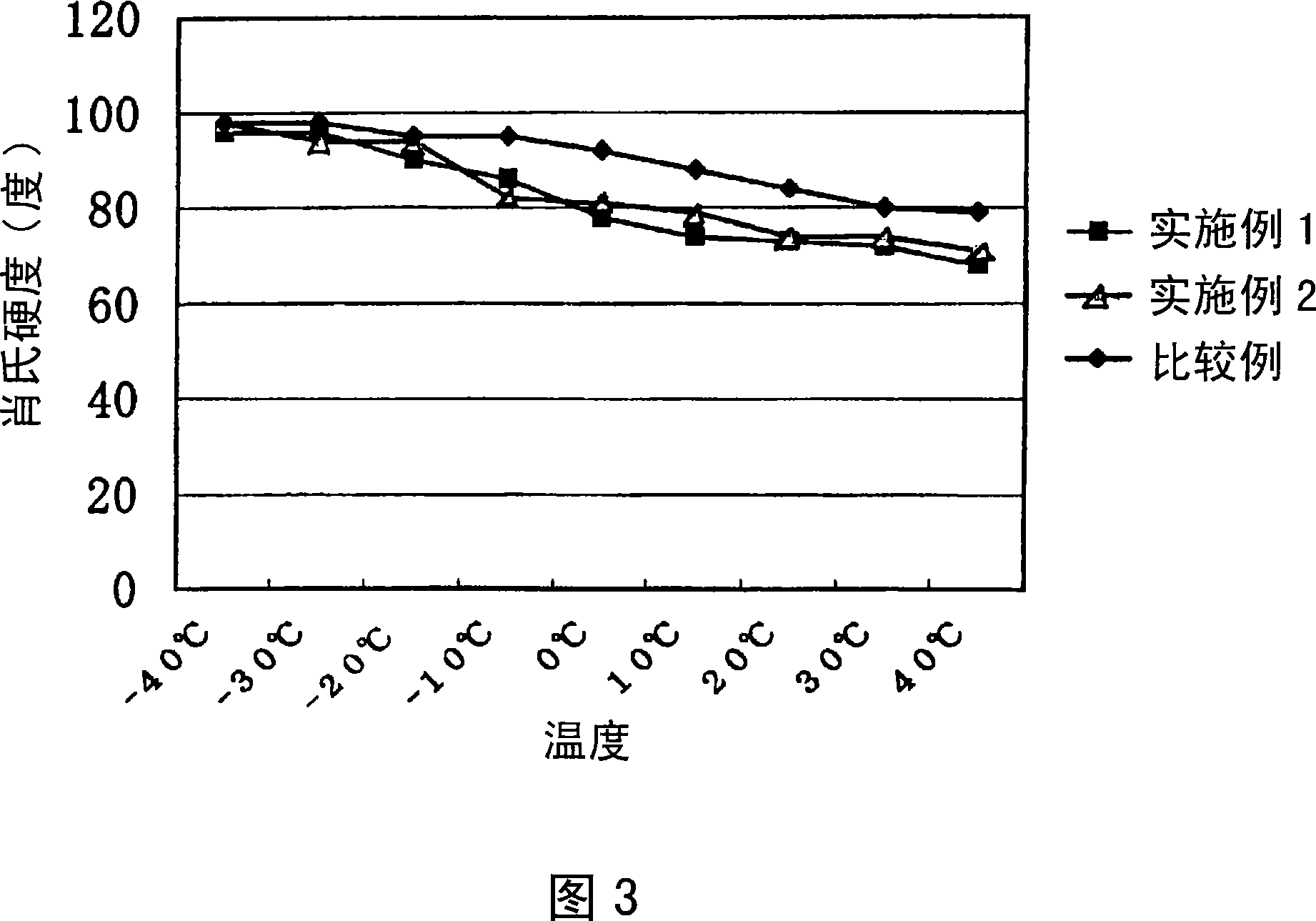

[0038] A resin interlayer with a thickness of 0.76 mm is sandwiched between two glass plates with a thickness of 2.0 mm that have been bent and processed, and laminated glass is produced by heating in an autoclave. The resin intermediate film used is a polyvinyl n-octyl acetal film (a film obtained by acetalizing polyvinyl alcohol with an aldehyde containing n-octyl aldehyde as the main component) between two polyvinyl butyral films. Three-layer structure of resin interlayer film. The measurement results of the Shore hardness measured by the durometer of the resin interlayer film of the laminated glass at 20° C. are indicated by the black square marks in FIG. 3 . The shore hardness at 20°C is 74 degrees, and in the temperature range of 0 to 40°C, the shore hardness changes in the range of 81 to 72 degrees. The hardness of the resin interlayer has a property that it becomes smaller when the temperature is raised, and becomes larger when the temperature is lowered.

[0039] In...

Embodiment 2

[0049] A laminated glass was produced in the same manner as in Example 1 using a polyvinyl acetal monolayer film (thickness 0.76 mm) using n-octaldehyde as a main component as an acetalized aldehyde as a resin intermediate film. The Shore hardness at 20° C. of the resin interlayer was 73 degrees, as indicated by the triangular mark in FIG. 3 . Using this resin interlayer, a laminated glass was produced in the same manner as in Example 1, and the natural vibration characteristics were measured in the same manner as in Example 1. As a result, the natural vibration characteristics were approximately the same as those of the laminated glass in Example 1 in the frequency range of 20 to 500 Hz. Vibration characteristics. Next, an actual car driving test was carried out on an automobile in which the laminated glass was installed as a windshield, and as a result, the continuous large cavity resonance noise (bass resonance noise) was hardly generated during running.

[0050] The lamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com