Method and device for thread distribution in a warping frame

A technology of rotating axis and yarn group, applied in the direction of transportation and packaging, other manufacturing equipment/tools, textiles and papermaking, etc., can solve problems such as delaying processing operations, and achieve the effect of speeding up the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

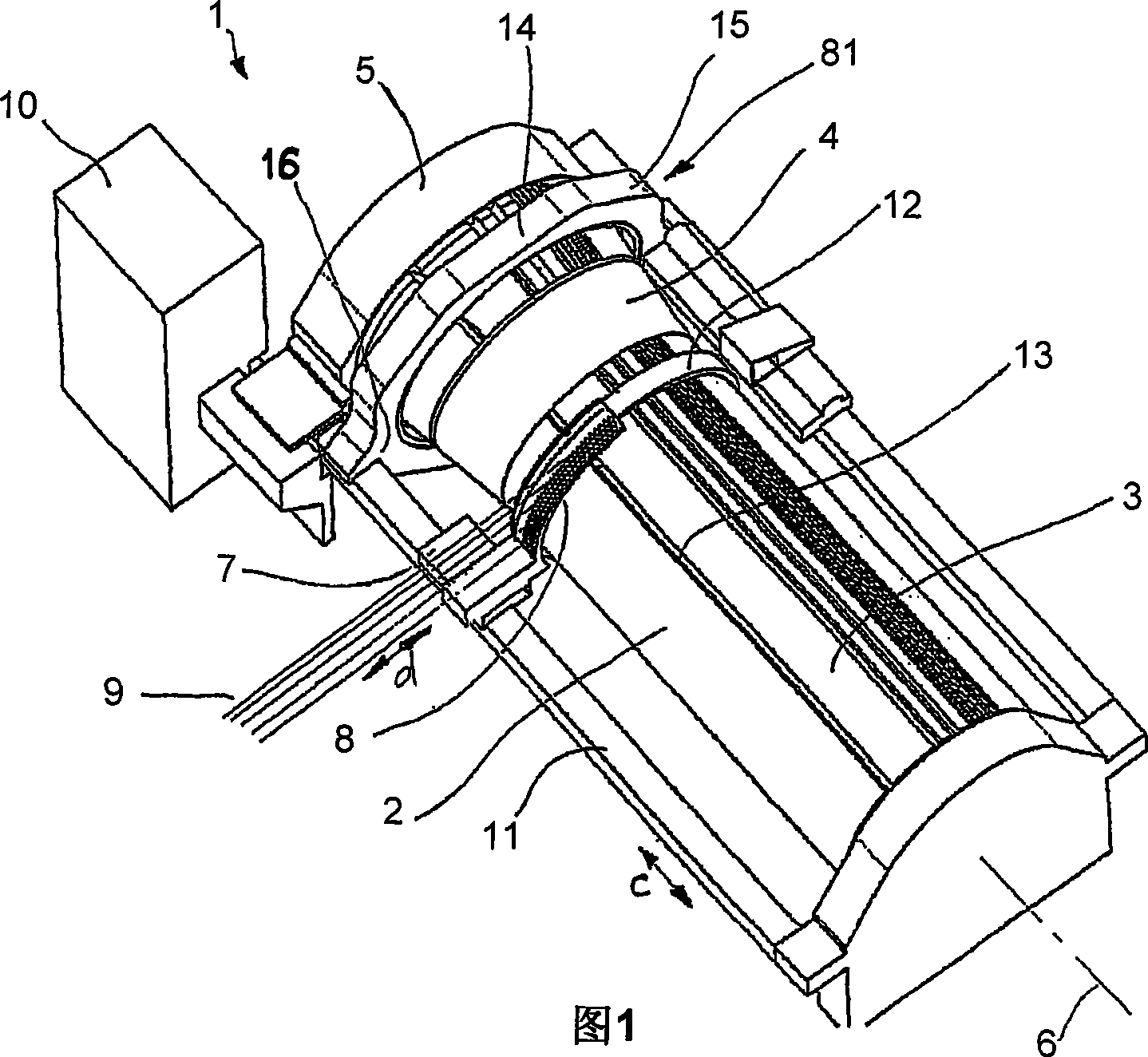

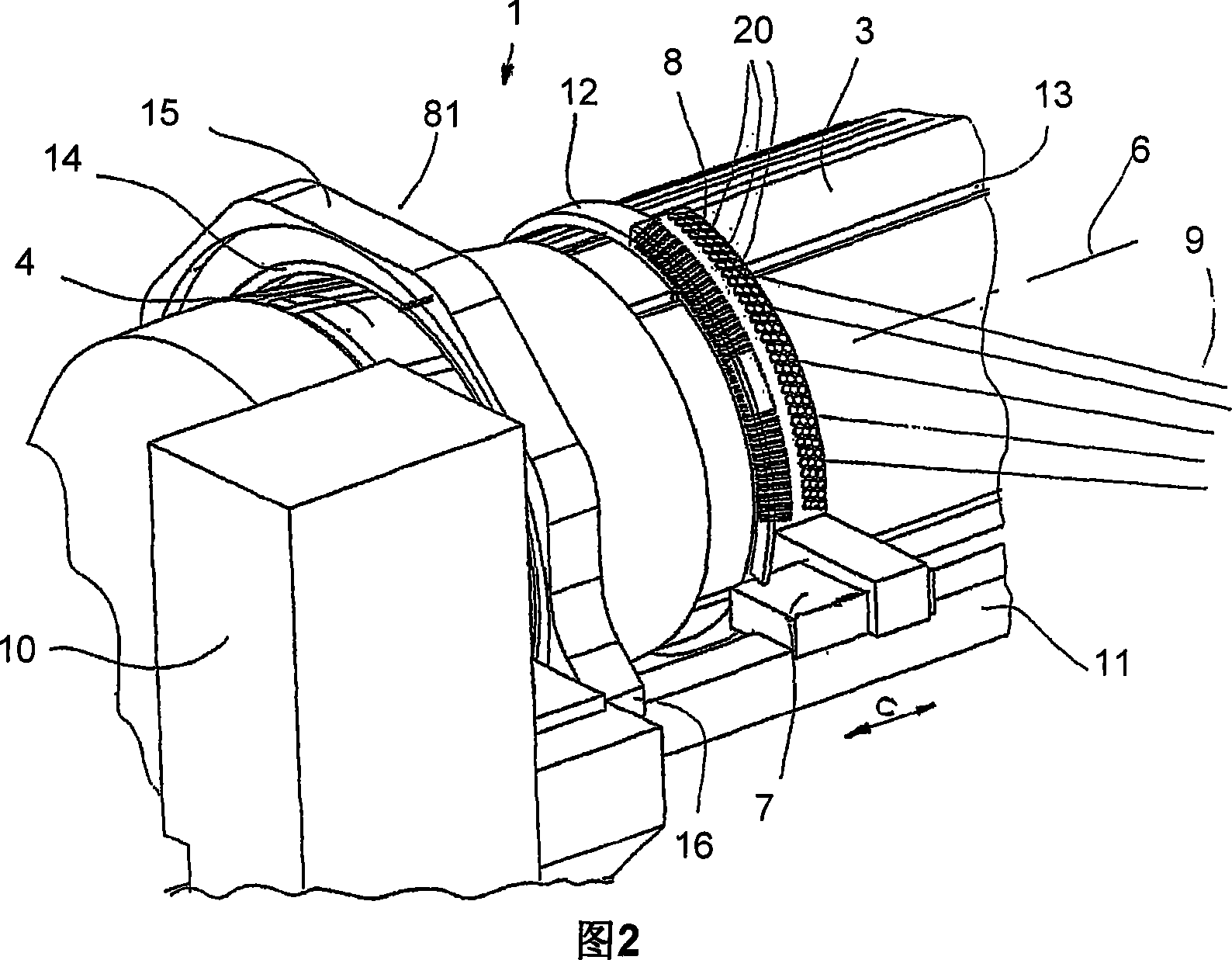

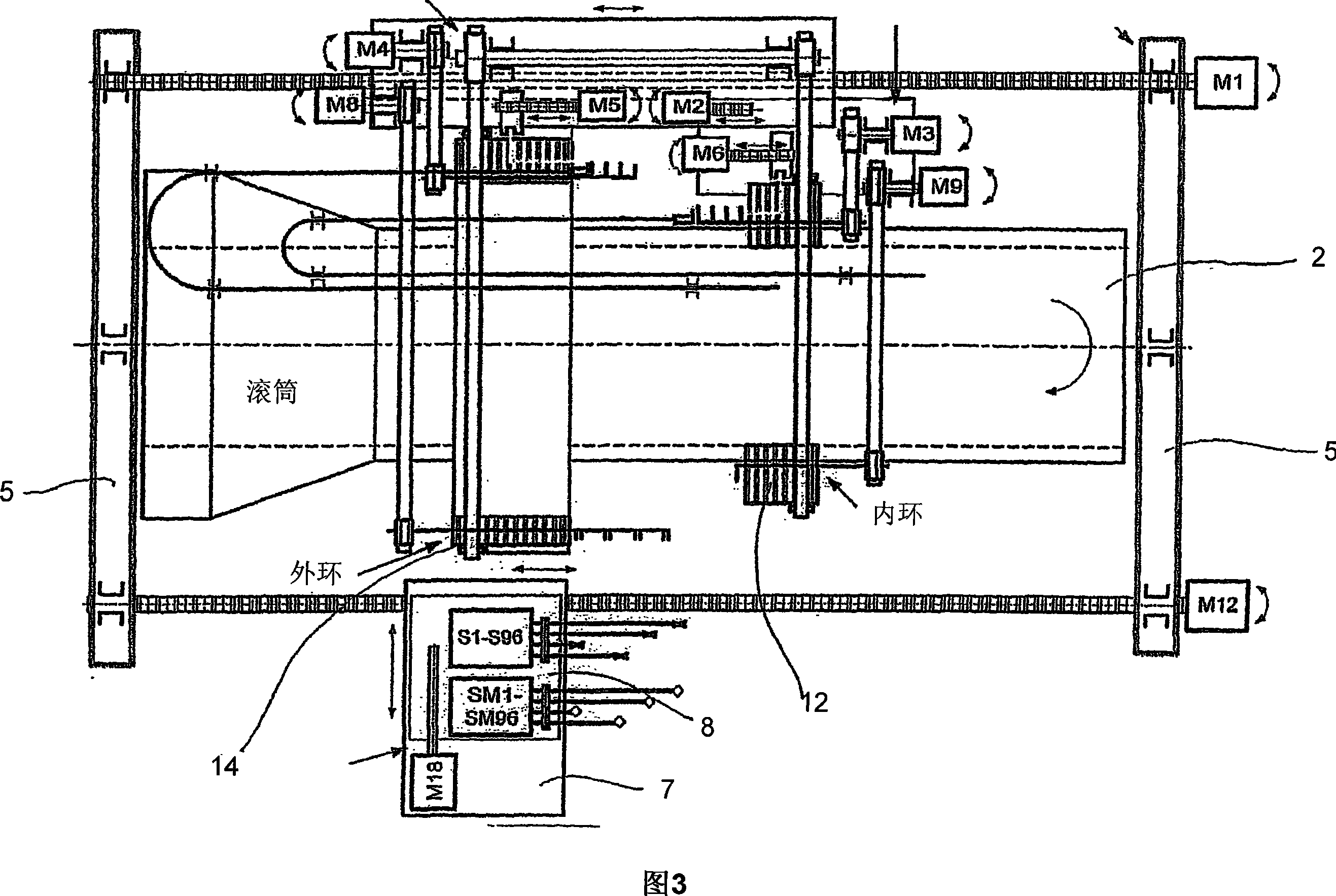

[0050] As shown in FIGS. 1 and 2 , the warping machine, generally designated 1 , consists essentially of a warping cylinder 2 as a winding body, which has a cylindrical section 3 and a conical section 4 . The warping cylinder is supported rotatably about a winding body axis or cylinder axis 6 in a frame 5 . The warping table 7 stands still on the guide mechanism 11 of the warping table, and the warping table can move in the arrow direction c parallel to the rotation axis 6 on the guide mechanism 11 . A yarn selection device 8 is provided on the warping table 7, and the yarn selection device can move relative to the warping cylinder in a direction perpendicular to the rotation axis of the warping cylinder (ie, arrow direction d).

[0051] The yarn selection device 8 itself surrounds the surface of the warping cylinder 2 in an arc of eg 90°. A plurality of thread guide modules 20 , which are only schematically represented here, are arranged on the thread selection device in a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com