Method for forecasting slurry performance in emulating horizontal directional drilling construction and its experimental device

A horizontally oriented and in-construction technology, applied in the field of construction engineering and trenchless horizontal directional drilling construction, can solve the problems of single mud, guide construction, and large difference, so as to reduce construction cost, shorten construction period, and reduce construction exploration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

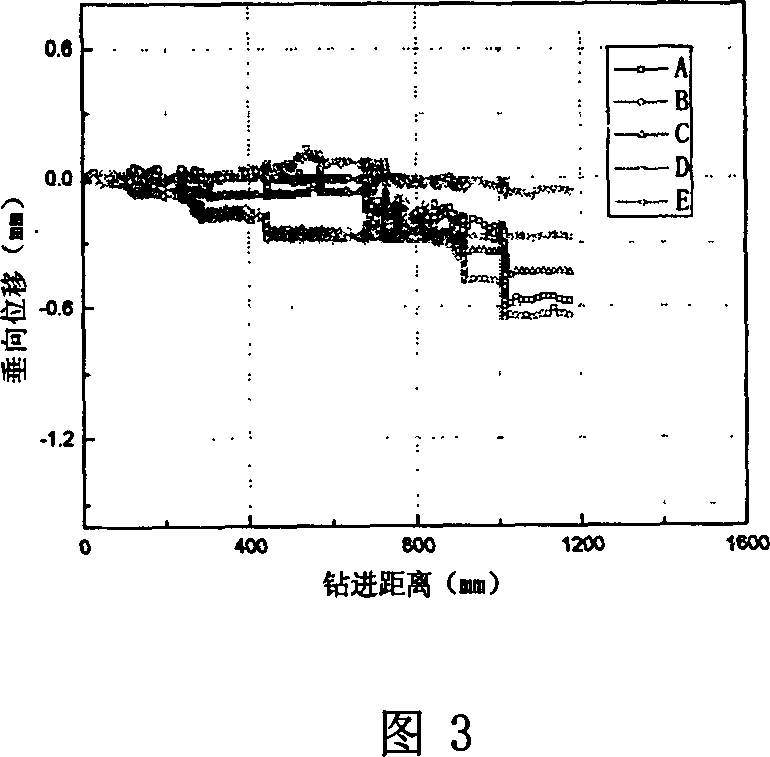

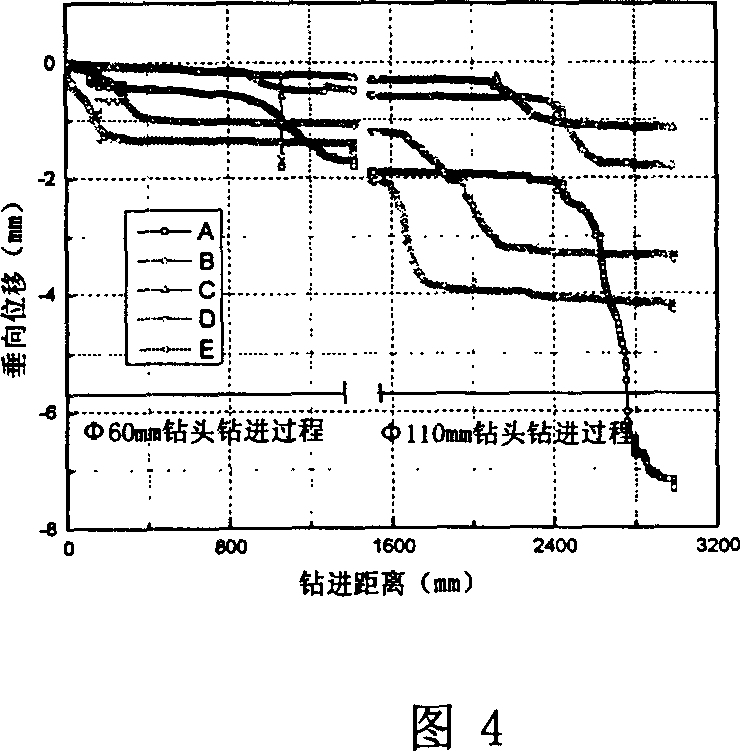

[0032] Accompanying drawing 3, Fig. 4 are the experiment result that same kind of mud is implemented in clay and sandy soil.

[0033] From accompanying drawing 3, as can be seen in Fig. 4, in the drilling process, the land subsidence that clay produces is obviously littler than the ground subsidence that sandy soil produces. In clay, the maximum ground subsidence is 0.6mm during the drilling process of Φ60mm drill bit, while in sandy soil, the maximum ground subsidence is 1.7mm, which is about 3 times that of clay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com