Container air-tightness detection method and its device

A technology of air tightness detection and detection device, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of slow detection speed and low degree of automation of small leaks, and achieve fast monitoring speed, high degree of automation, The effect of simple detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

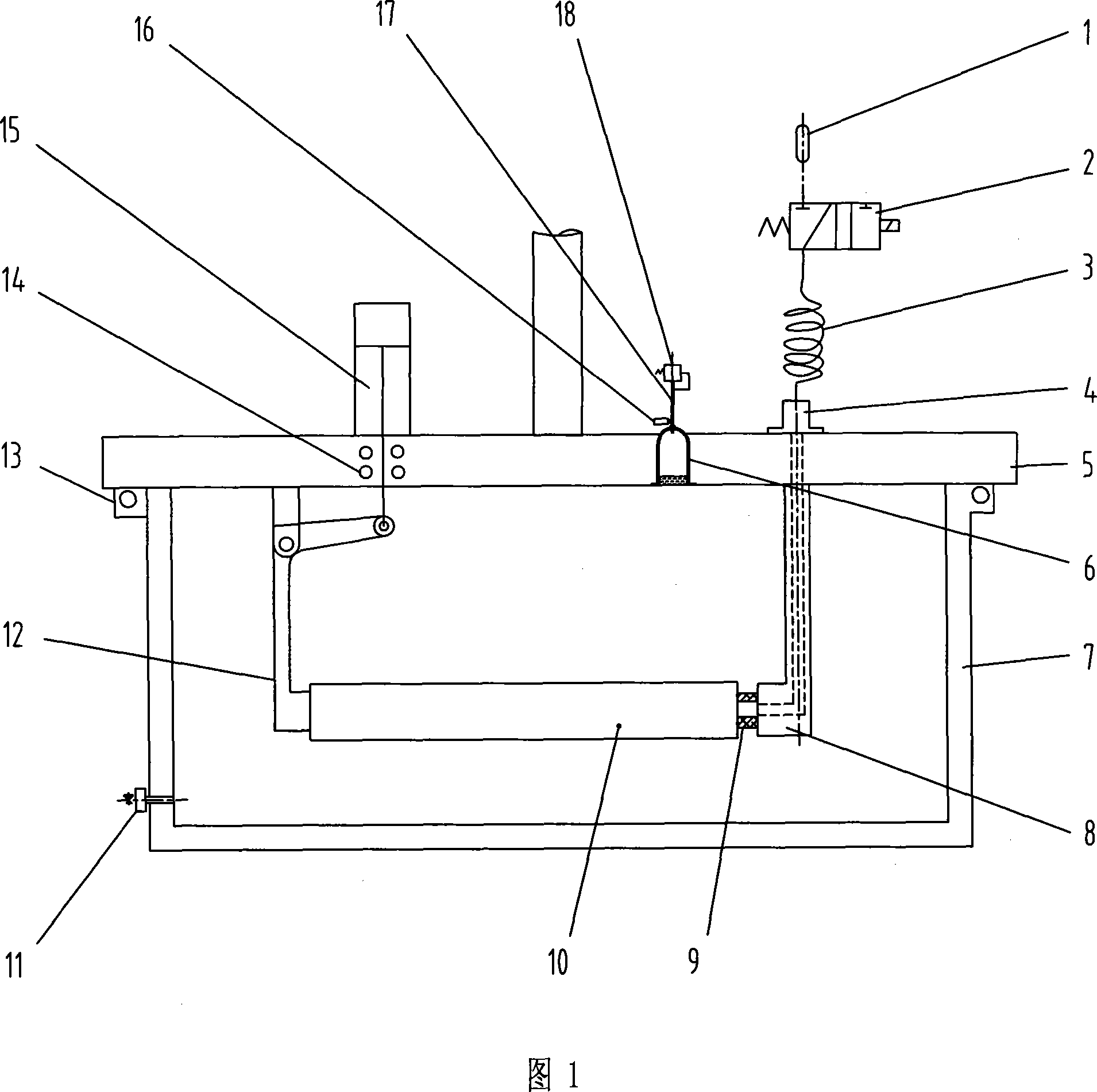

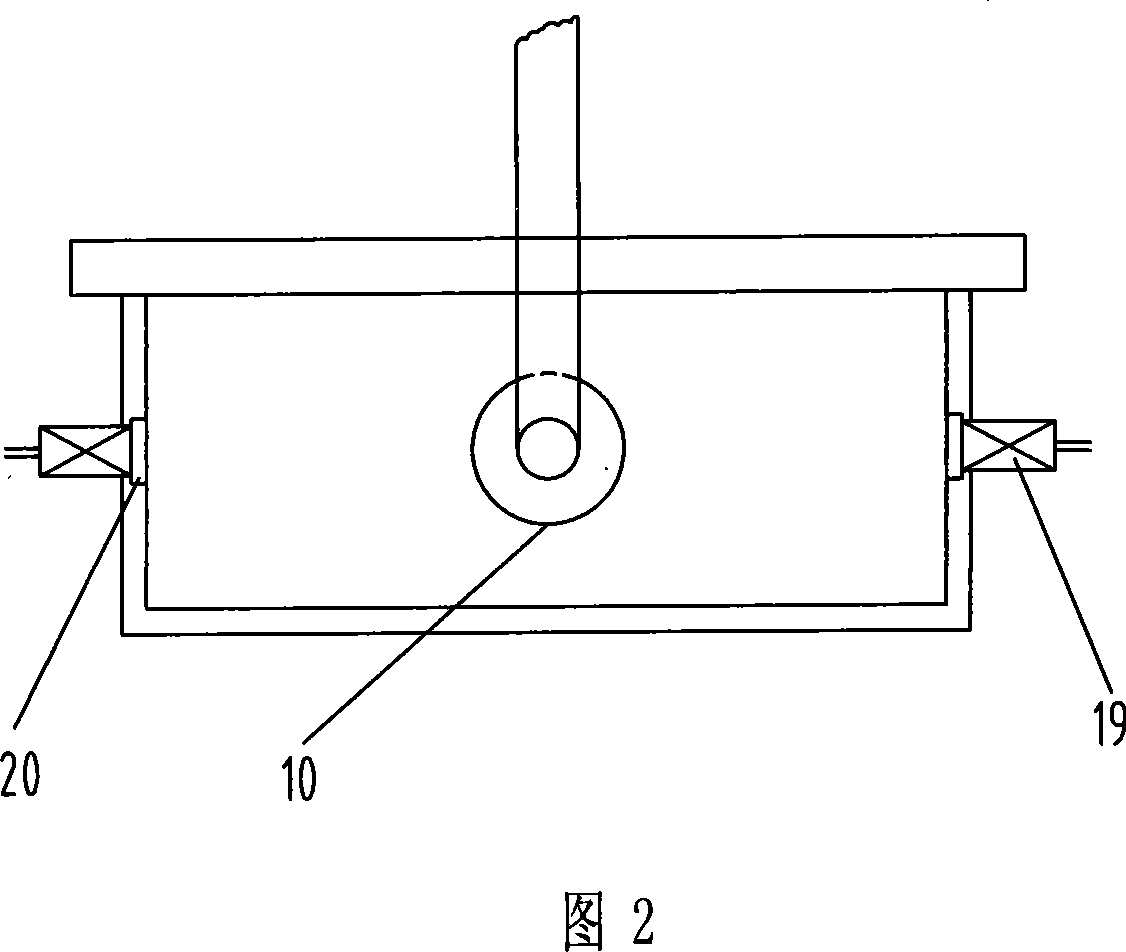

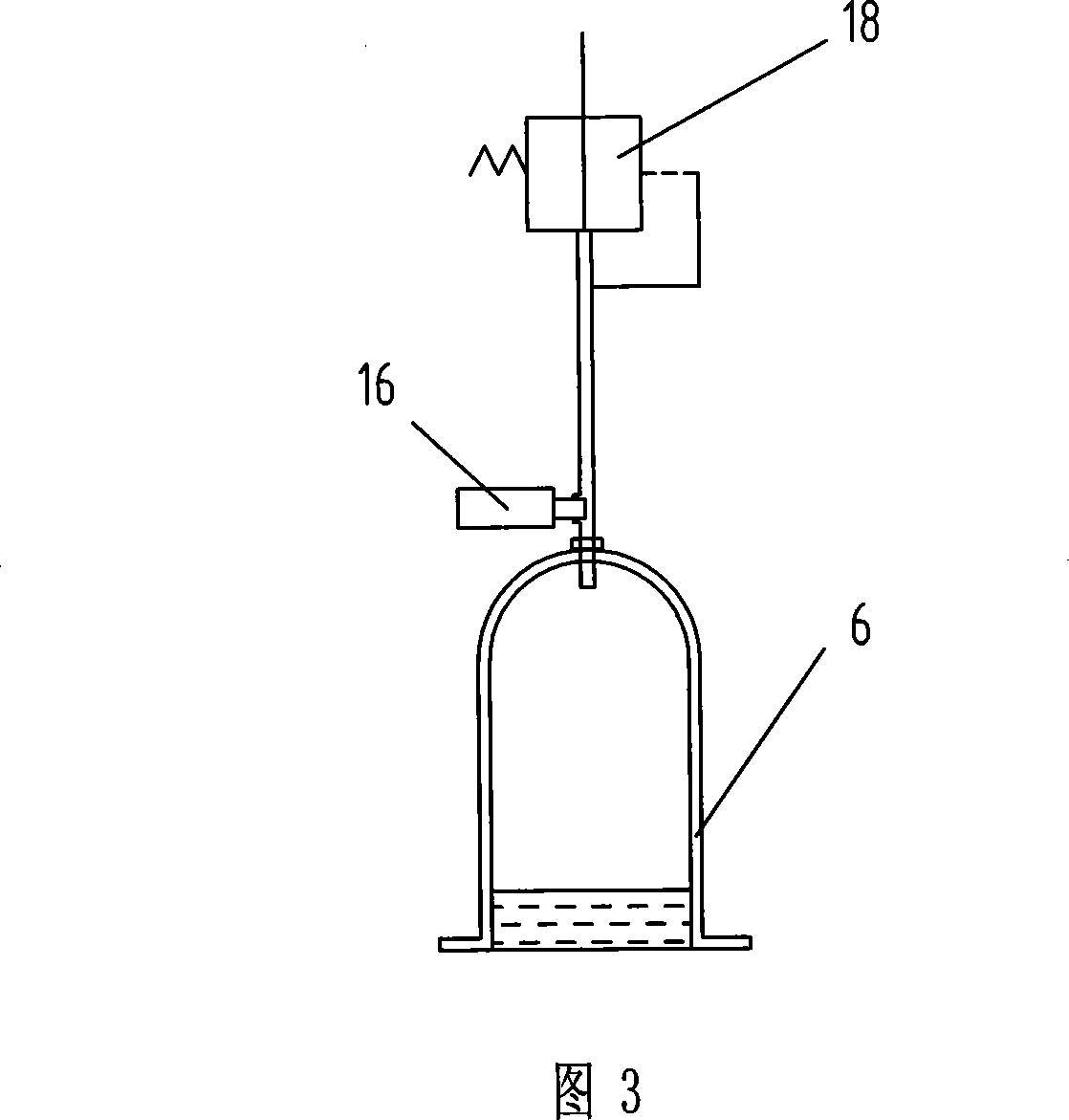

[0033] The airtightness detection method of the present invention is to firstly put the container to be tested into the detection device, and make it connected with the inflatable part and then fix it in the detection device; then, seal the detection device, and inject water to retain one and the pressure detection part Then the compressed air is injected into the detected container through the inflatable part; the pressure of the air chamber is detected by the pressure detection part; if the pressure increases, the detected container leaks; if it does not increase, it means that it is detected The airtightness of the detection container is good. The air chamber pressure signal detected by the aforementioned pressure detection part can be transmitted to the control part; if the signal transmitted to the control part indicates that the detected container is leaking, the camera part on the detection device can be controlled to take pictures of the leaking part of the detected con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com