Backlight module and liquid crystal display containing the backlight module

A technology of liquid crystal display and backlight module, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of partial unevenness of the display screen and traces of the thermal conductive sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

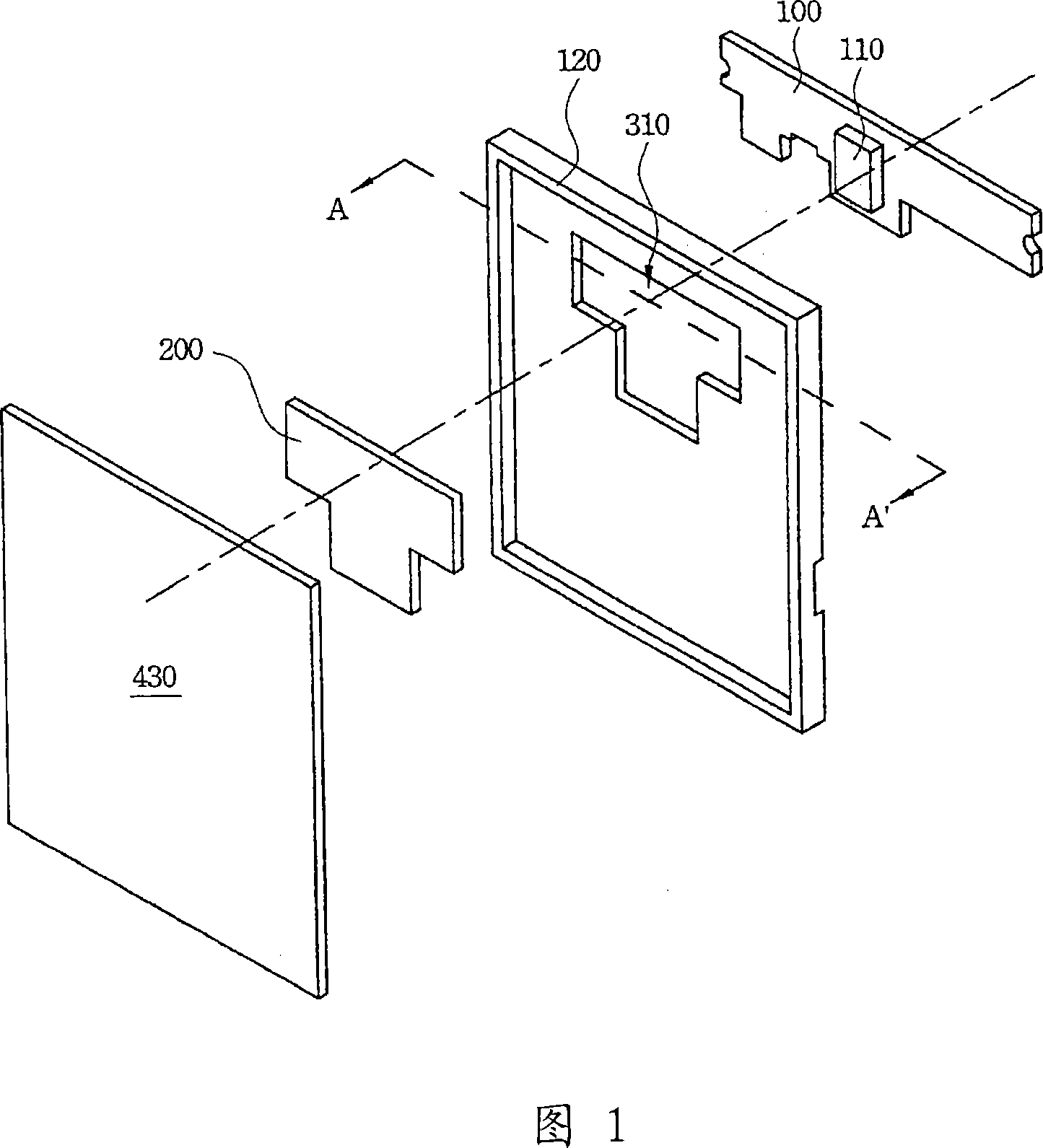

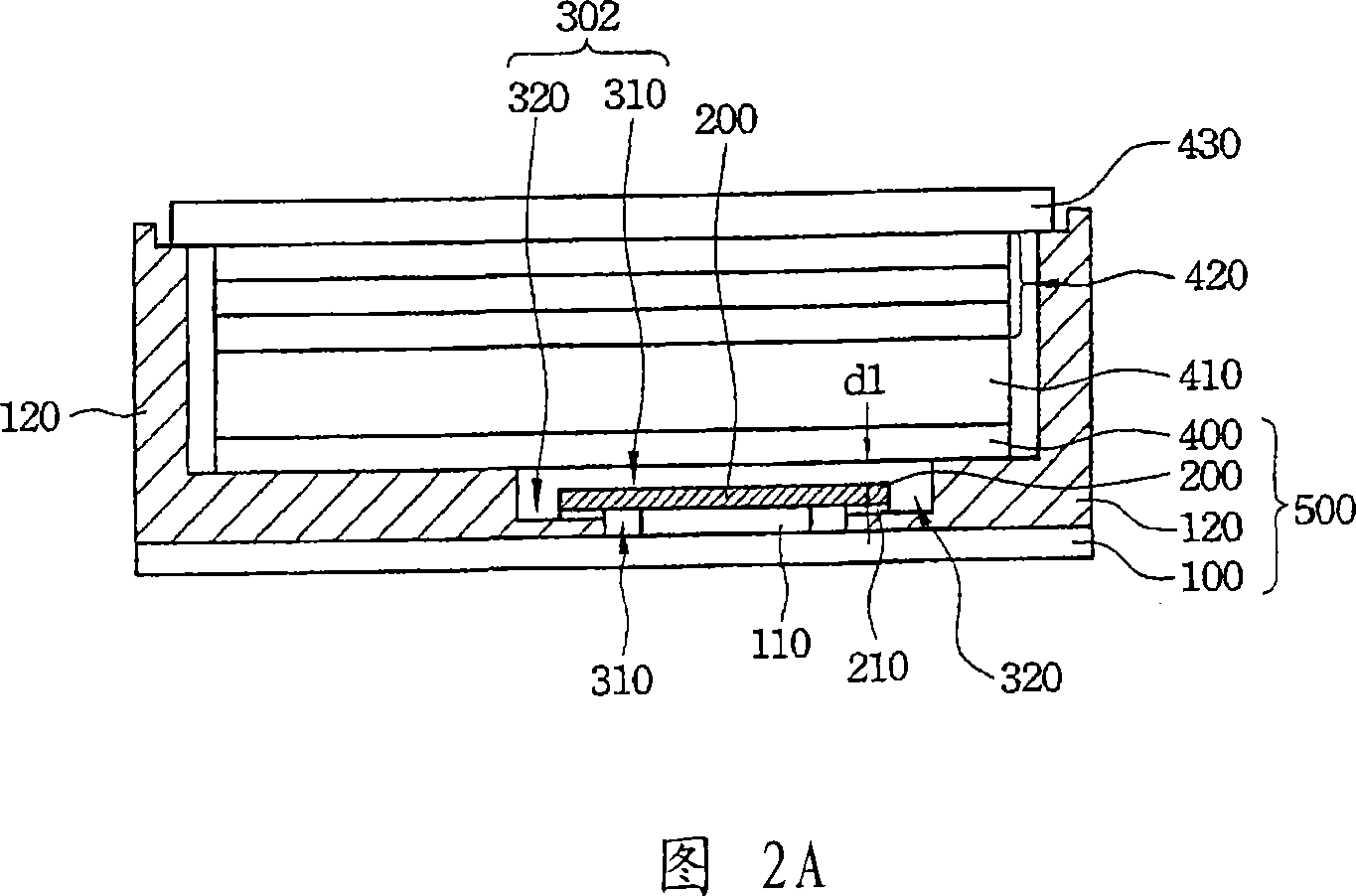

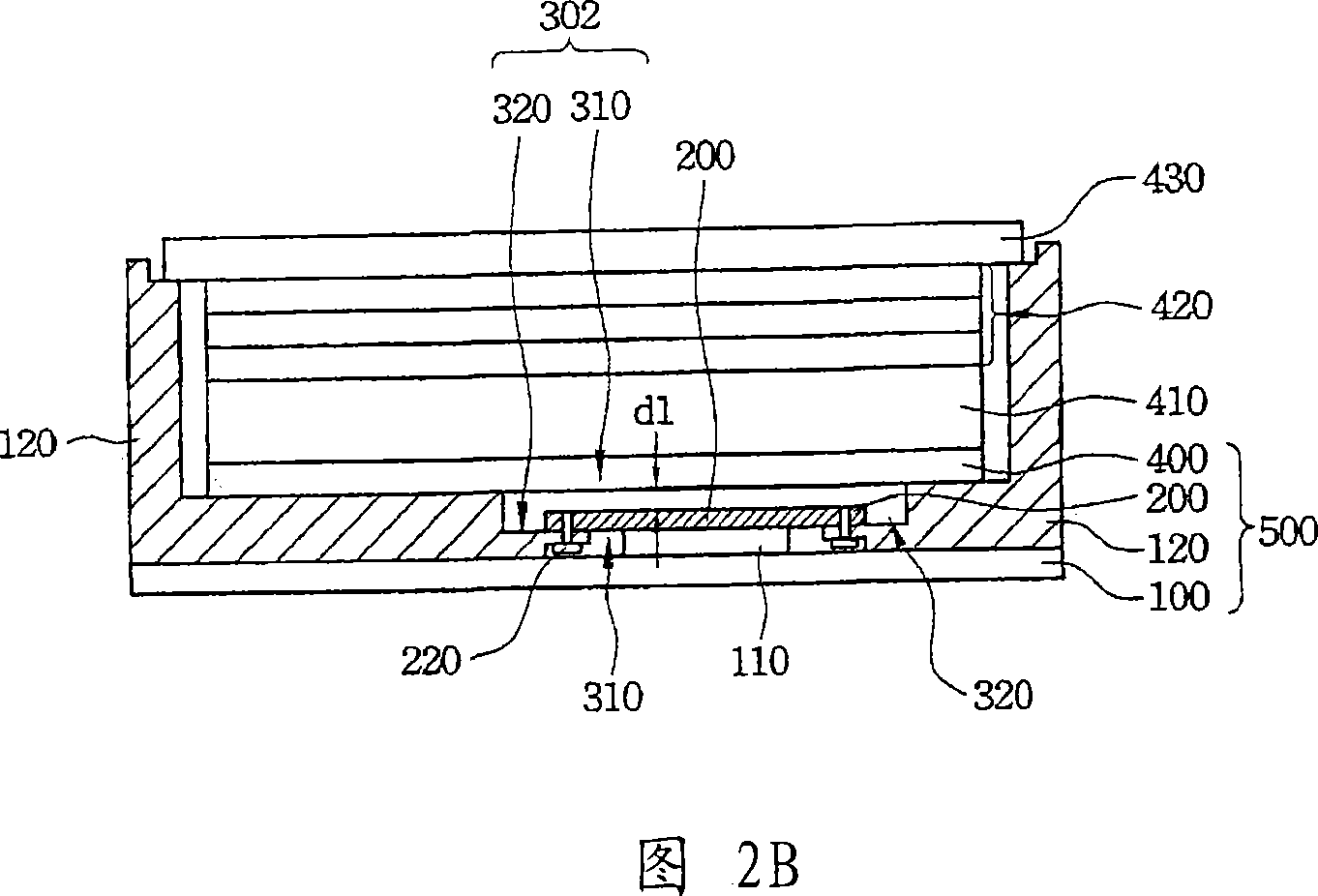

[0031] Please refer to FIG. 1 , which shows an exploded view of a liquid crystal display according to an embodiment of the present invention, in which the type of the stepped through hole is not specified. This liquid crystal display at least includes: circuit board 100, frame 120, heat conducting plate 200 and liquid crystal display unit 430, wherein at least one through hole 310 is formed in the bottom of frame 120 (Fig. 1 only draws a through hole for illustration), in order to At least one electronic component 110 of the circuit board 100 is accommodated (only one electronic component is shown in FIG. 1 for illustration), and the heat conduction sheet 200 is disposed on the sidewall of the through hole 310 . Between the frame 120 and the liquid crystal display unit 430, at least one optical film (not shown), a light guide plate (not shown) and a reflective sheet (not shown) are arranged, and the optical film, the light guide plate and the reflective sheet will be drawn Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com