Diesel particulate filter system with meta-surface cavity

一种微粒过滤器、过滤器的技术,应用在膜过滤器、分散颗粒过滤、机器/发动机等方向,能够解决目标热点和冷点、不符合微粒过滤器再生的要求等问题,达到提高均匀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

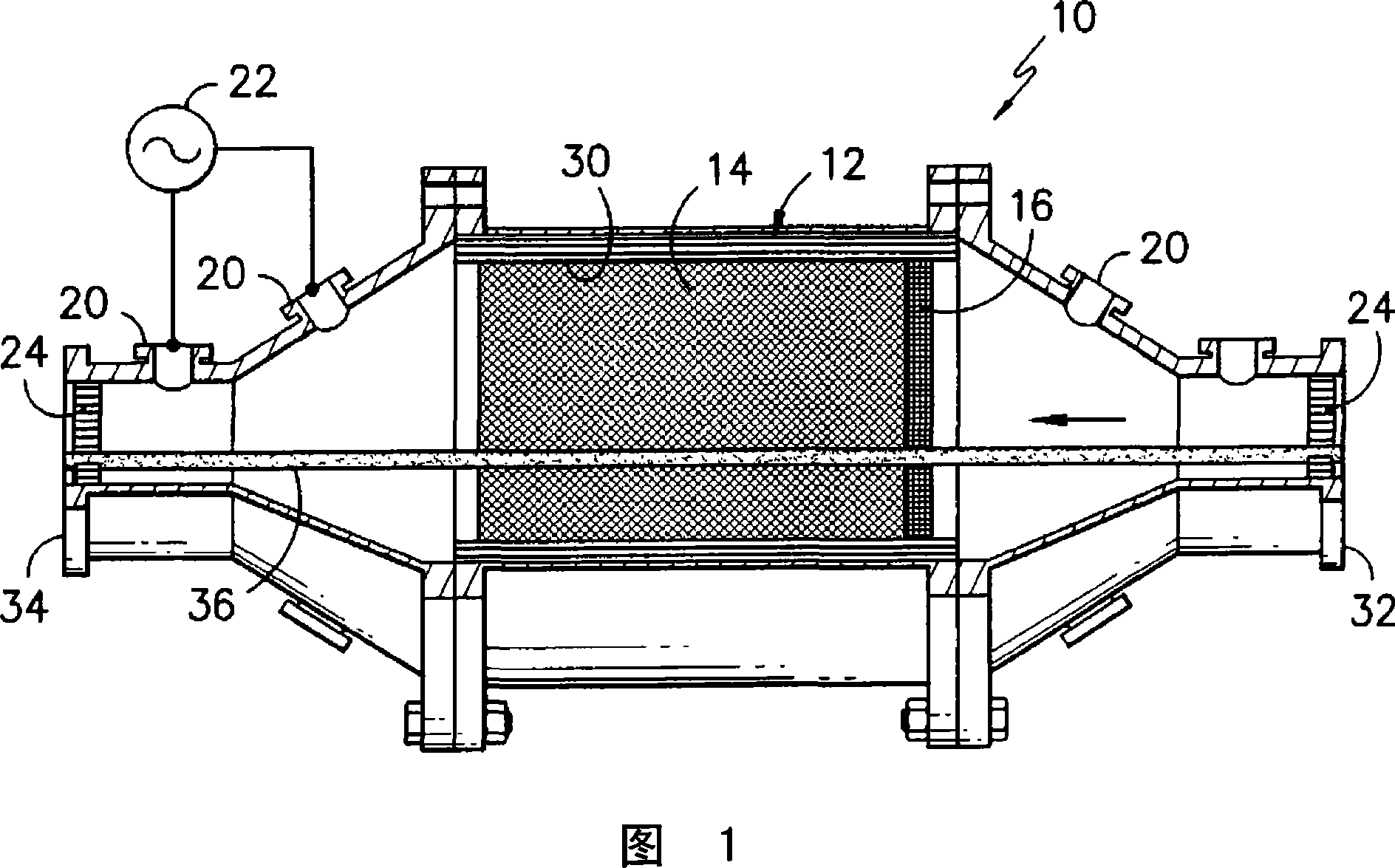

[0013] The several figures will now be numbered, wherein like parts are given corresponding reference numerals throughout the several figures, to the extent permissible. In FIG. 1 , a diesel particulate filter device 10 is shown disposed along an exhaust gas flow path downstream from a diesel engine (not shown). The direction of air flow is shown in the figure with arrows indicating direction. According to the illustrated construction, the diesel particulate filter comprises a cavity portion 12 for accommodating a porous ceramic filter 14 and a microwave-absorbing material 16 disposed substantially across a cross-section of the filter 14 at Embed contact relationships. The microwave-absorbing material 16 may be any known substance or combination that can undergo heating when exposed to microwave radiation. For example, such materials may include SiC (silicon carbide), ITO (indium tin oxide), various ferrites, etc., materials known to those skilled in the art.

[0014] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com