Thermoplastic resin composition and forming article

A technology for thermoplastic resin and composition, applied in the field of thermoplastic resin composition and its molded products, can solve the problems of viscosity decrease of thermoplastic resin composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

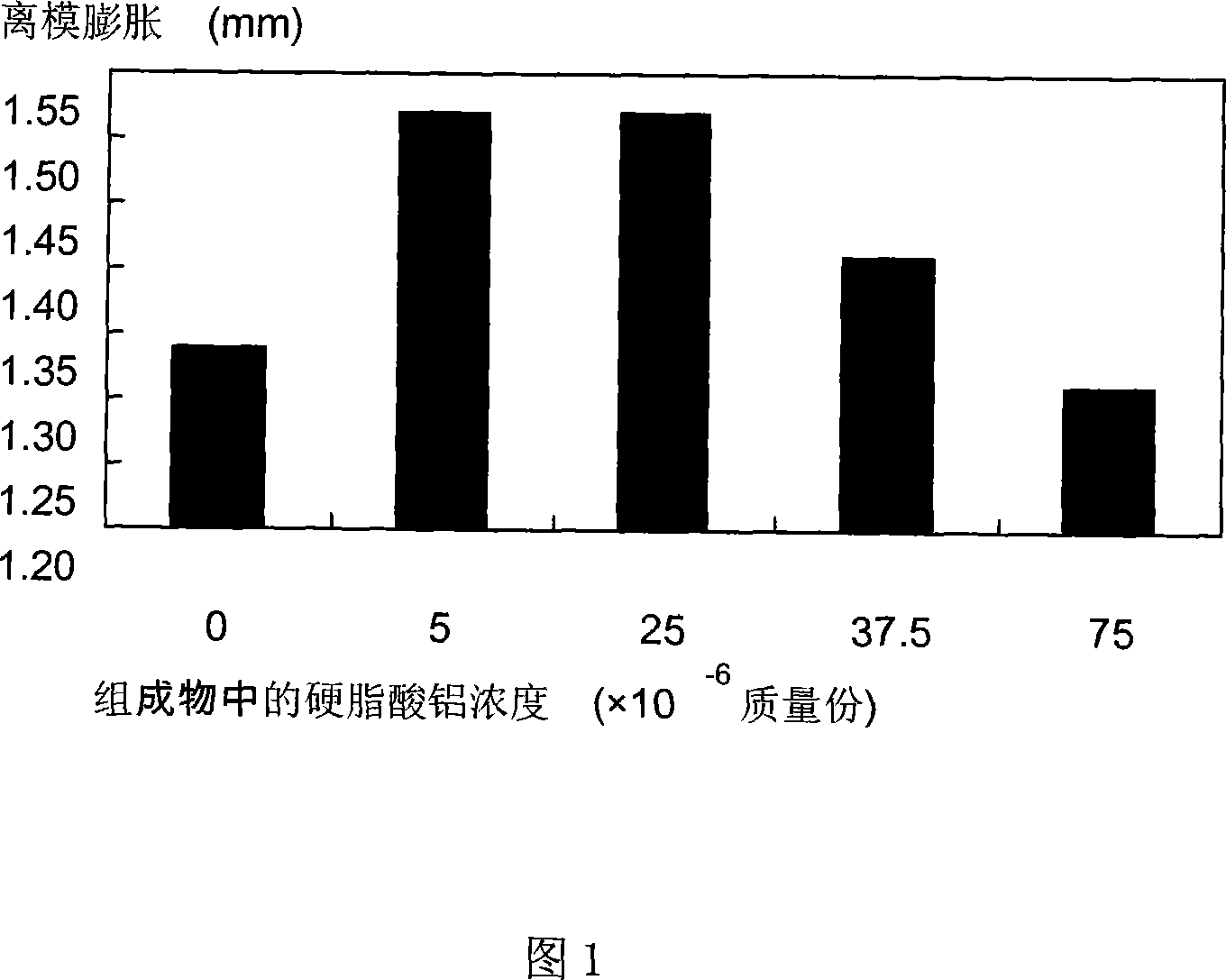

Image

Examples

Embodiment

[0071] (Manufacture of Polymer 1)

[0072] The oil jacket of a pressurized stirred tank reactor (capacity: 1 liter) equipped with an oil jacket was heated up to 200°C. On the other hand, 69 parts by mass of styrene (hereinafter referred to as St.), 30 parts by mass of glycidyl (glycidyl) methacrylate (methacrylate) (hereinafter referred to as GMA.), 1 part by mass of methacrylic acid Methyl methacrylate (hereinafter abbreviated as MMA.), 15 parts by mass of xylene 15 parts by mass, and 0.5 part by mass of ditertiarybutyl peroxide (ditertiarybutyl peroxide) (hereinafter abbreviated as DTBP) as a polymerization initiator .) After the monomer mixture is prepared, add it to the raw material tank. Then, the monomer mixed liquid was continuously supplied from the raw material tank to the reactor, and the reaction liquid was continuously recovered from the outlet of the reactor so that the mass of the liquid in the reactor remained constant at about 580 g. The feed rate of the mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap