Concentrated food having rehydration characteristics and the processing method

A food and property technology, applied in bakery, food preparation, food science, etc., can solve the problems of high oil content and no rehydration characteristics, and achieve the effects of easy digestion and absorption, improved food acceptability, and rapid rehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

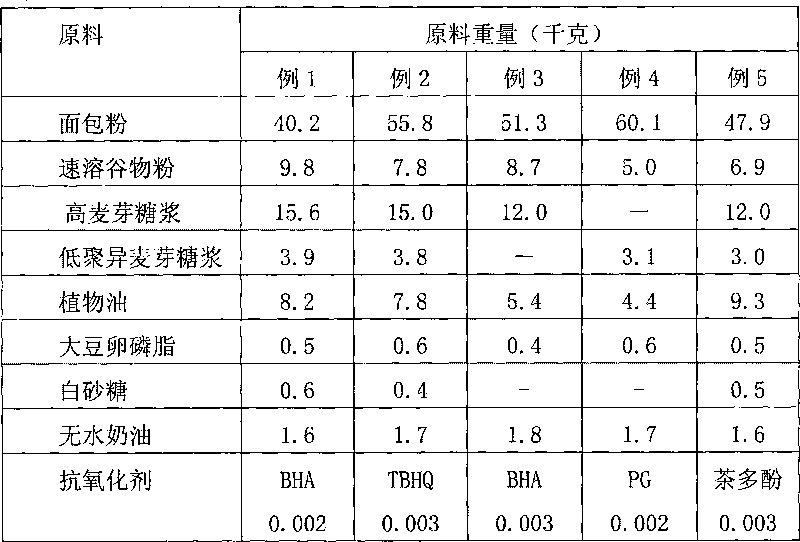

[0054] 1. Raw material composition, refer to Table 1.

[0055] Table 1:

[0056]

[0057] 2. Operation process:

[0058]1. Mixing for the first time: Weigh the granular materials bread flour, instant grain powder, white sugar, etc. and mix them evenly, then atomize 70-85% of the syrup or mixed syrup through an atomizer and add to the mixed In the granular material, continue to mix;

[0059] 2. Baking: Baking the material in step 1 at 160-180°C for 15-20 minutes, then cooling;

[0060] 3. The second mixing: melt vegetable oil, soybean lecithin, anhydrous butter, and antioxidants and then mix with the remaining syrup, atomize and add to the cooled material in step 2, mix well and then cool;

[0061] 4. Briquetting forming: input the materials in step 3 into the briquetting machine for briquetting;

[0062] 5. Packaging: step 4: packaging, bagging, and vacuum packaging of briquetting materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com