Plate non-return valve with lateral downstream and control edge

A check valve and edge technology, which is used in the field of controlling the flow direction of the medium in the automobile, can solve the problems of opening the check valve, damaging the consumption of the connection, and the check valve cannot be opened according to the purpose, so as to reduce the impact speed and reduce the Noise generation and fatigue strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

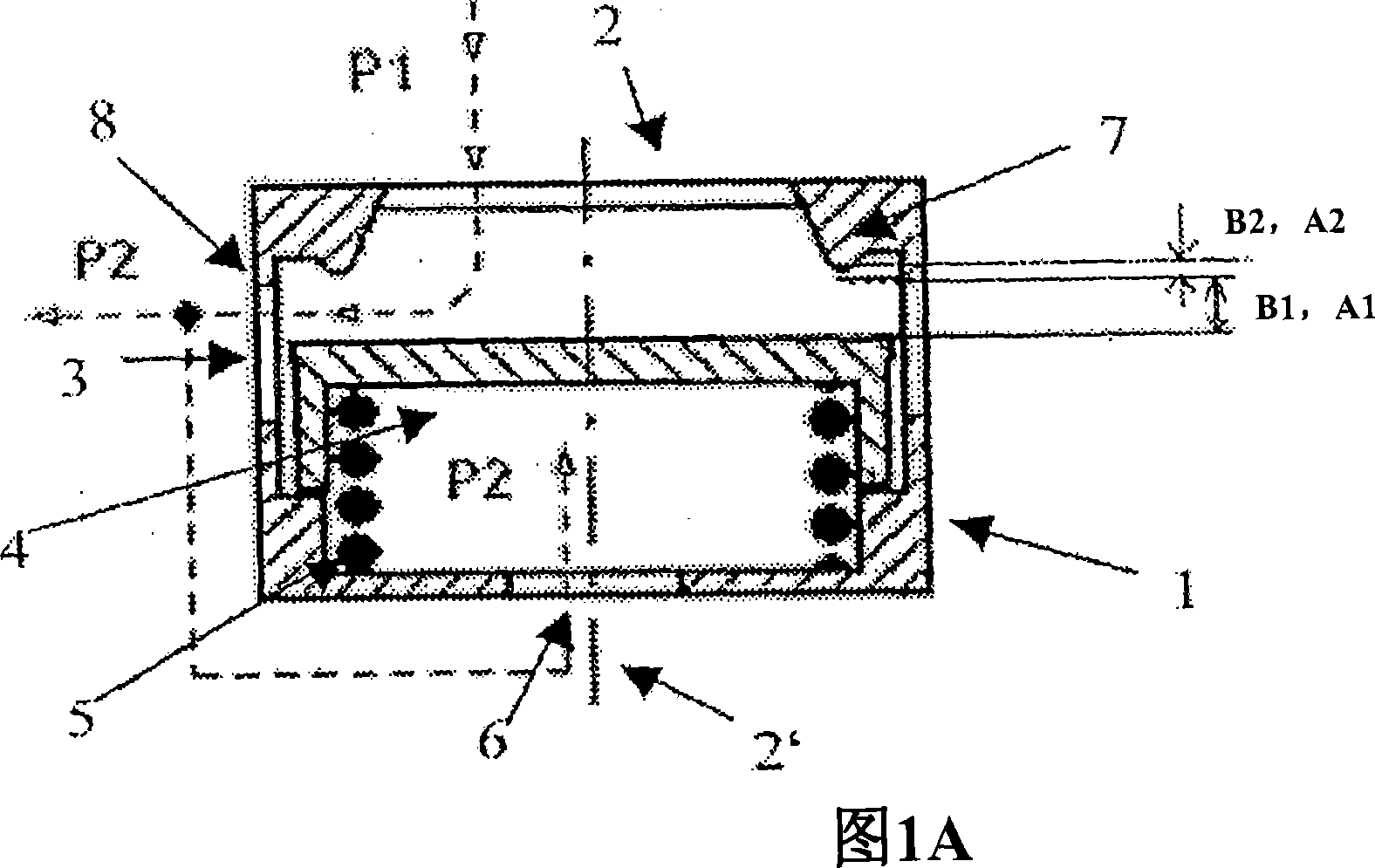

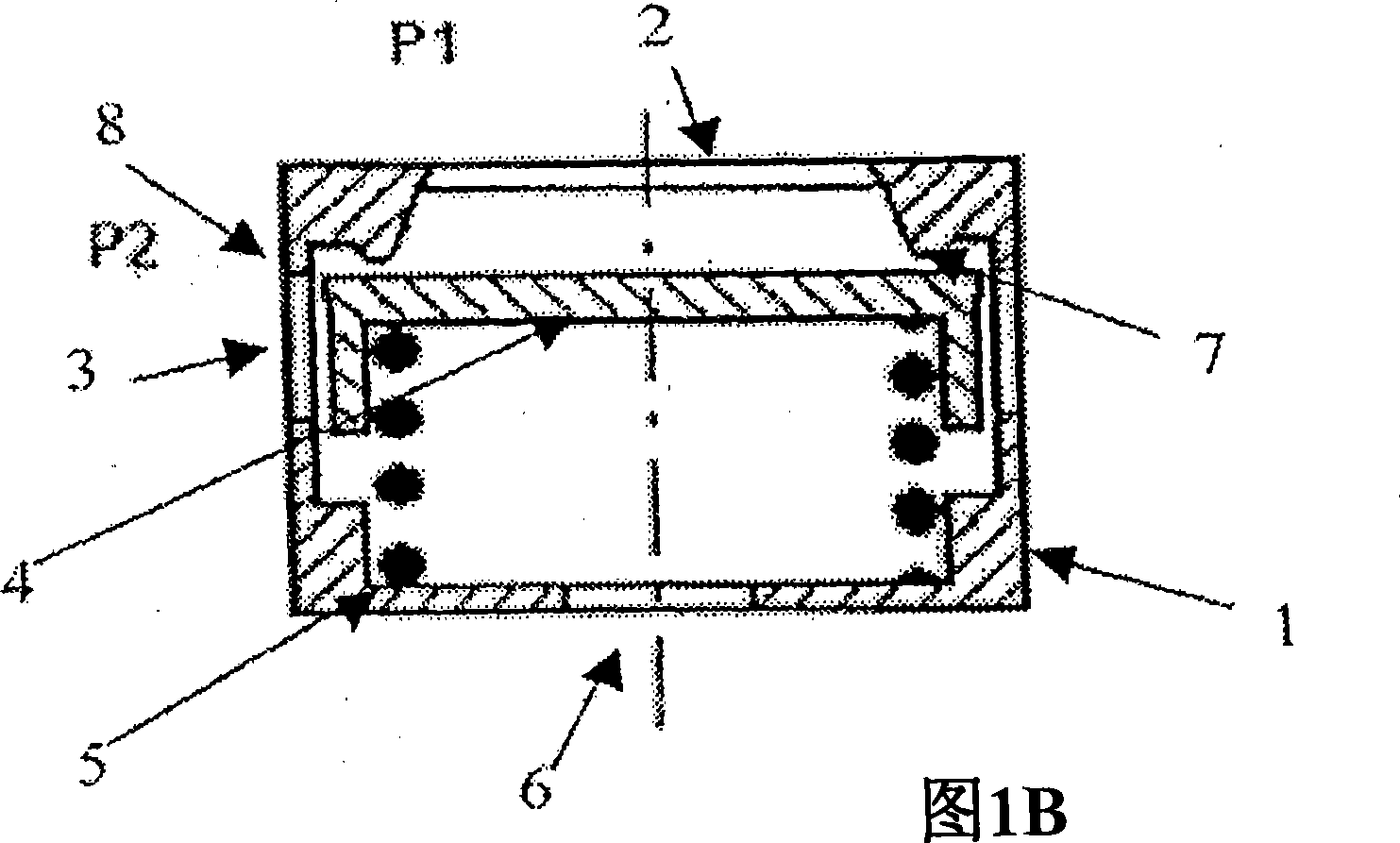

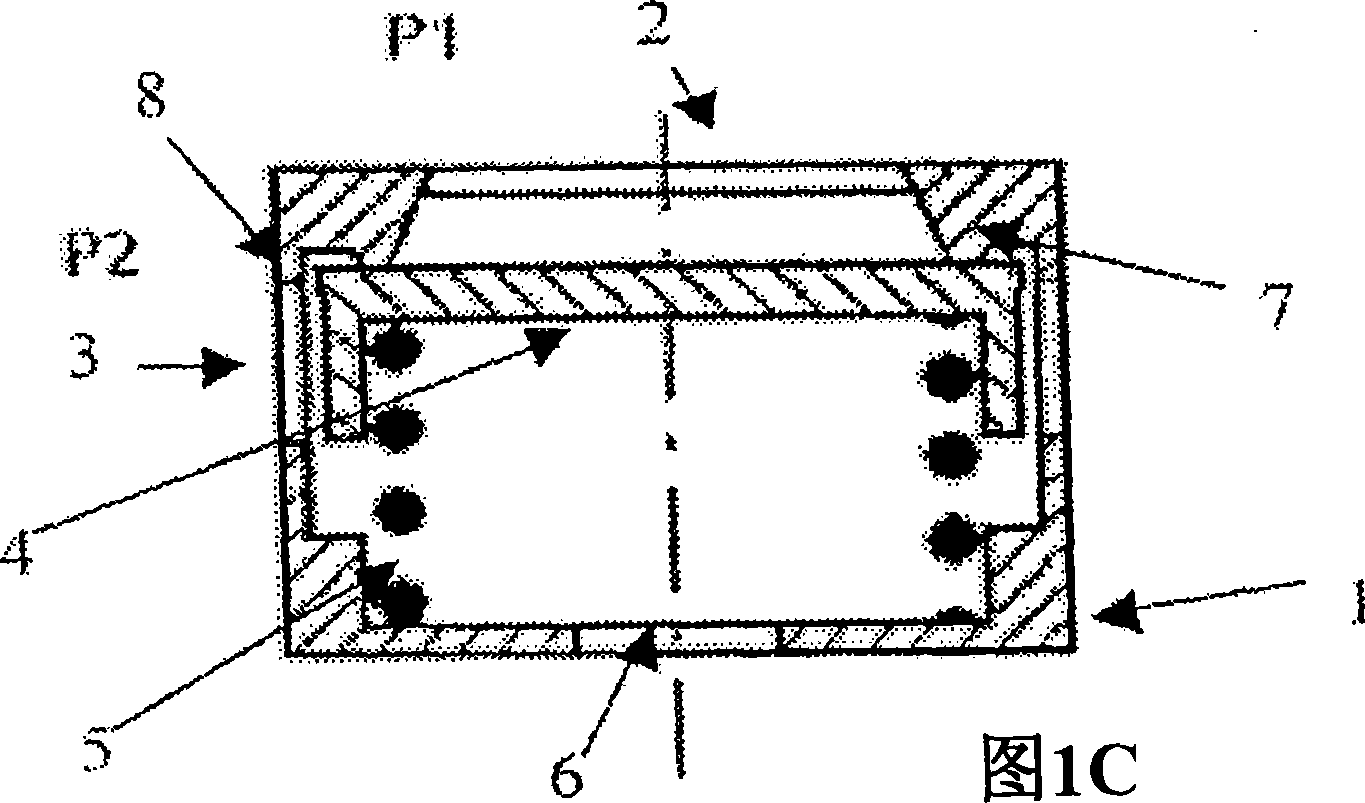

[0034] The same or similar components are provided with the same symbols in different figures. The presentations are schematic and not comprehensive.

[0035] 1A to 1C show a check valve device for an automobile according to an exemplary embodiment of the present invention. The non-return valve has a valve sleeve 1 with an inflow opening 2 and an outflow opening 3 , and a valve element 4 which is displaceably mounted in the valve sleeve 1 . When the valve element 4 is in the first position, a first flow cross section A1 between the outflow opening 3 and the valve element 4 is adjusted ( FIG. 1A ). The outflow connection 3 is closed by the valve element 4 when the valve element 4 is in the second position. Therefore no flow cross section is provided. When the valve element 4 moves in the first movement area B1 and the second movement area B2, the liquid flow cross-section A will change continuously. Wherein, the continuous change of the liquid flow cross-section A in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com