Installation and process for calcining a mineral load containing a carbonate in order to produce a hydraulic binder

A technology of mineral materials and carbonates, which is applied in lighting and heating equipment, cement production, clinker production, etc., and can solve the problems of increasing pollution and emission of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

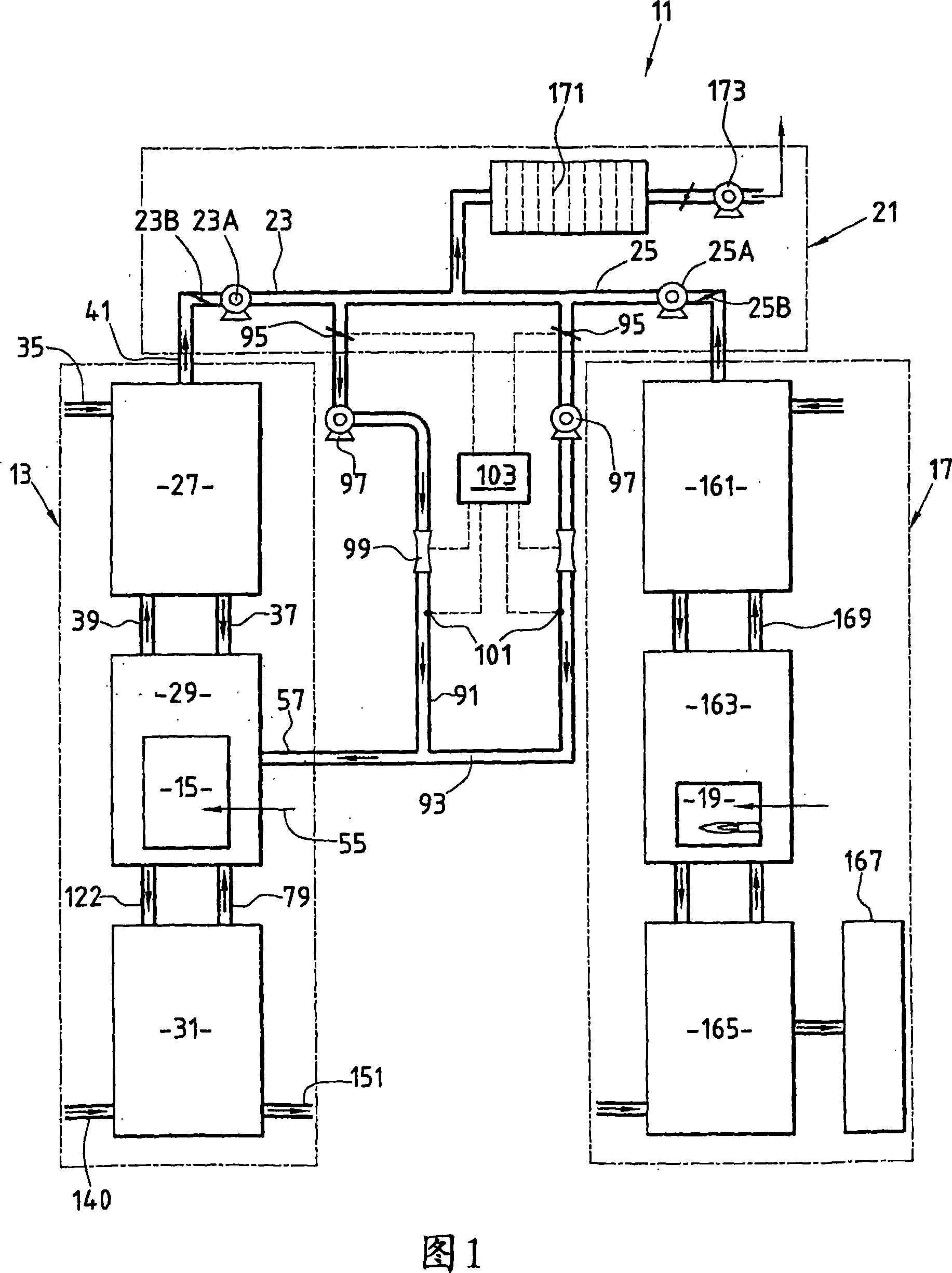

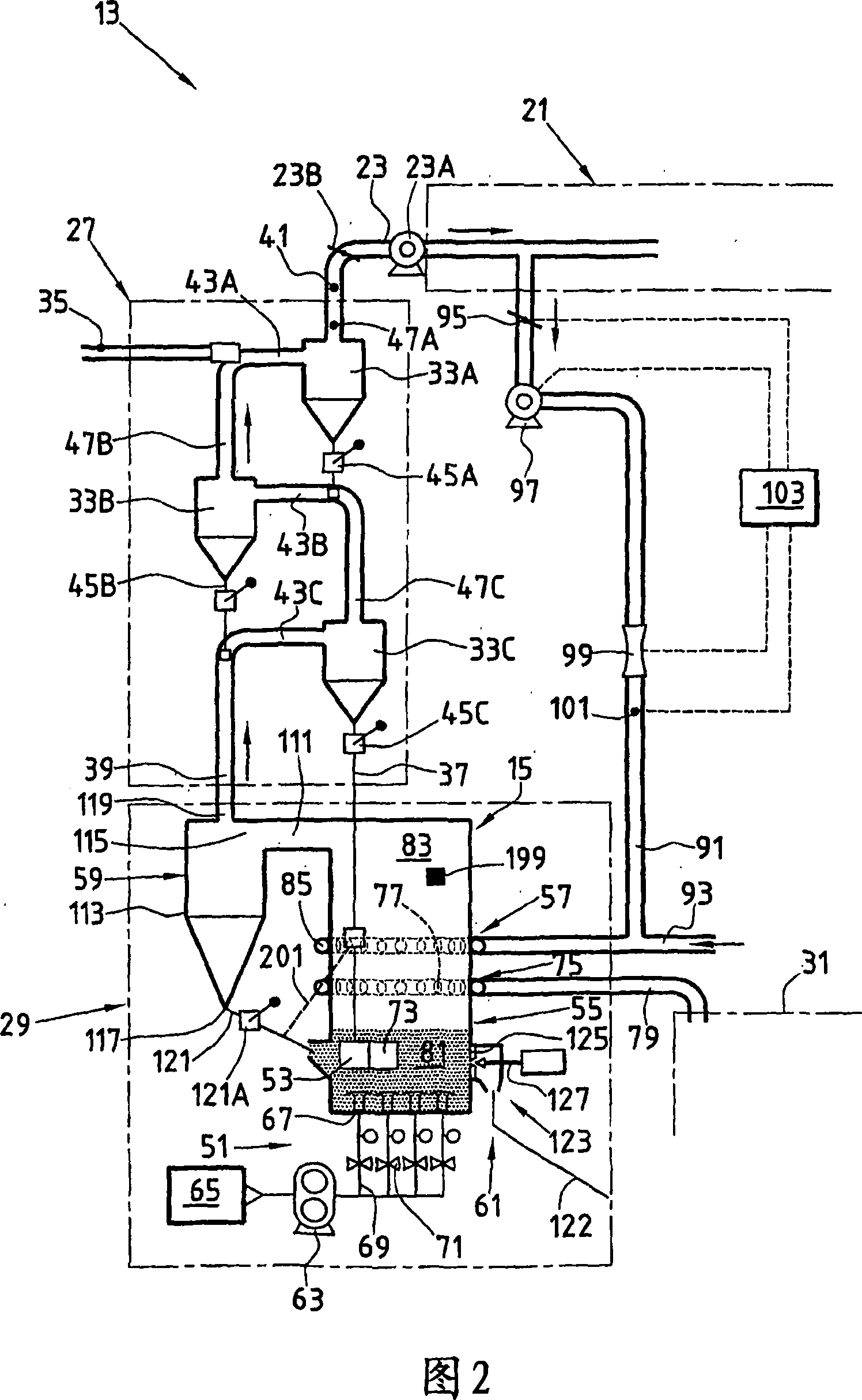

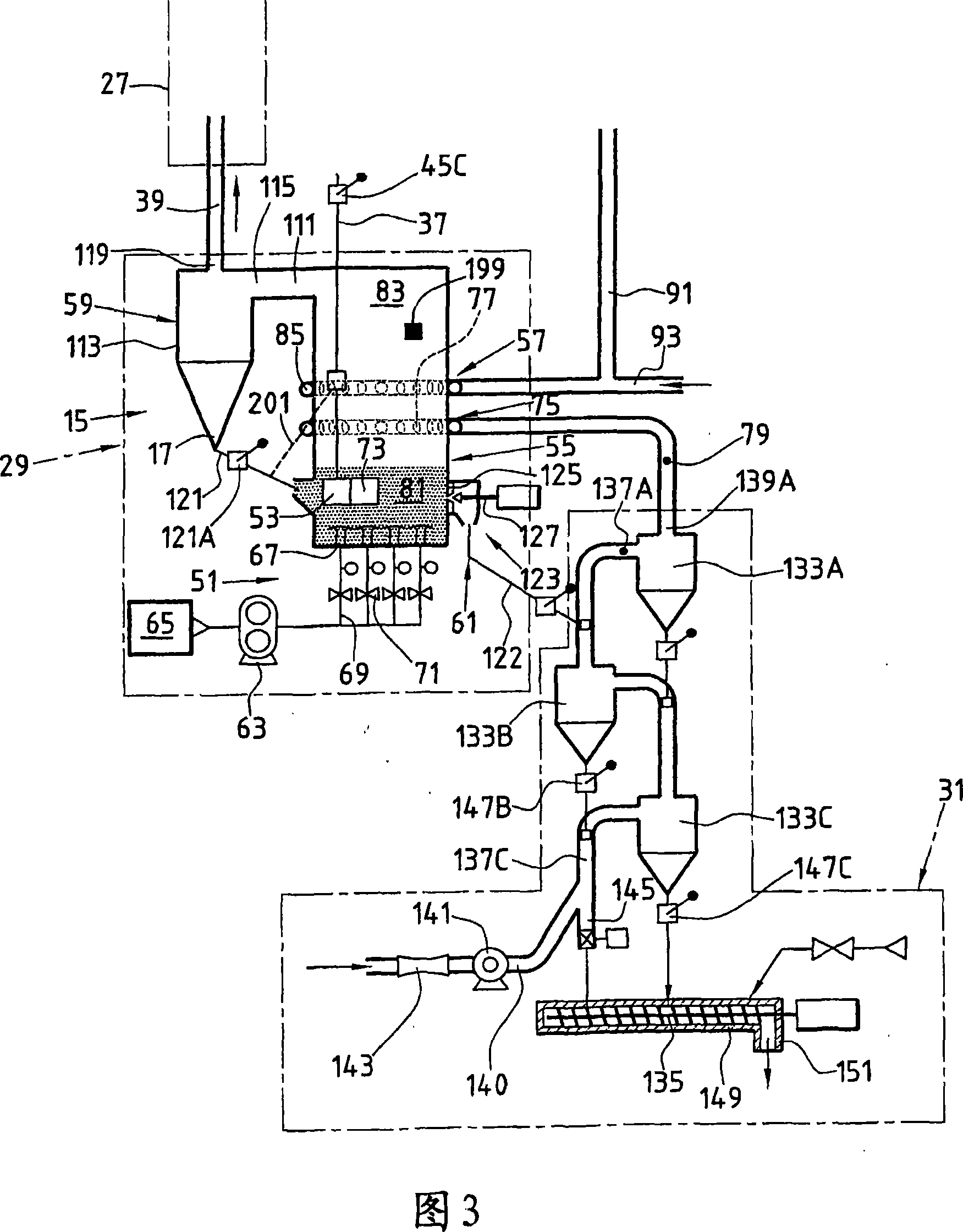

[0051] [51] The roasting plant 11 of raw mineral materials as shown in Figure 1 includes a "kalsin" binder production device 13 - which is equipped with a fluidized bed combustion combustion chamber 15, and at the same time, a sintering material production device 17 - It is equipped with a combustion converter 19 .

[0052] [52] The device 11 also includes a discharge unit 21 that discharges the combustion smoke into the atmosphere. The discharge unit 21 has a discharge channel 23 that discharges the combustion smoke generated in the fluidized bed combustor 15, and also has a Additional discharge duct 25 - which discharges the combustion fumes generated in the combustion converter 19 .

[0053] [53] Each guideway 23, 25 is equipped with a ventilator 23A, 25A and a ventilator regulating device 23B, 25B, and the ventilator regulating device 23B, 25B is, for example, a vane or a variable speed ventilator for The respective flow rates of the gases circulating in the respective de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com