Rotary separating and planting mechanism with offset elliptic gear of walking rice transplanter

An elliptical gear and rice transplanter technology, which is applied in the direction of gear transmission, belt/chain/gear, transplanting machinery, etc., can solve the problems of floating seedlings, large hole openings for transplanting seedlings, inverted seedlings, etc. The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

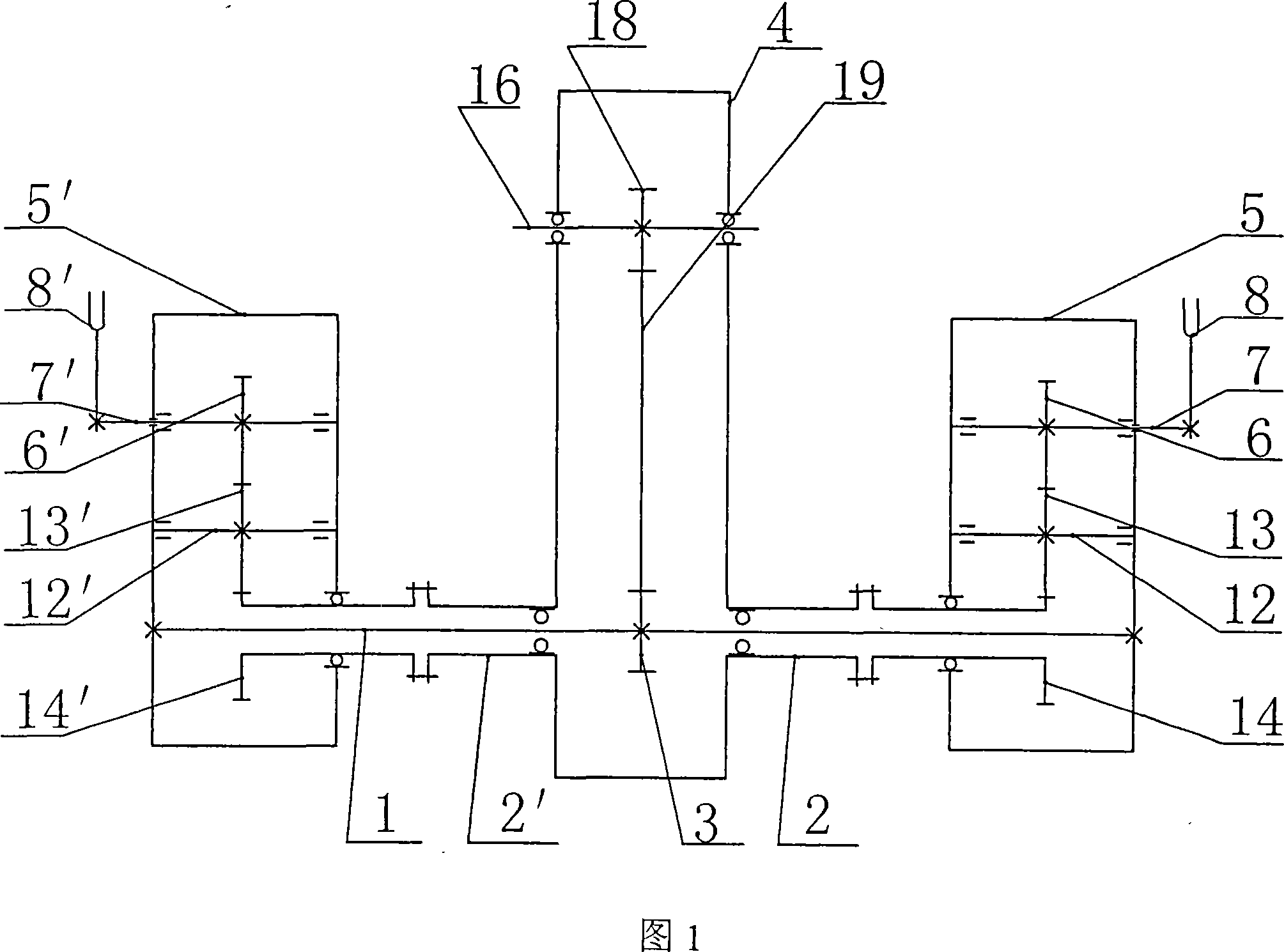

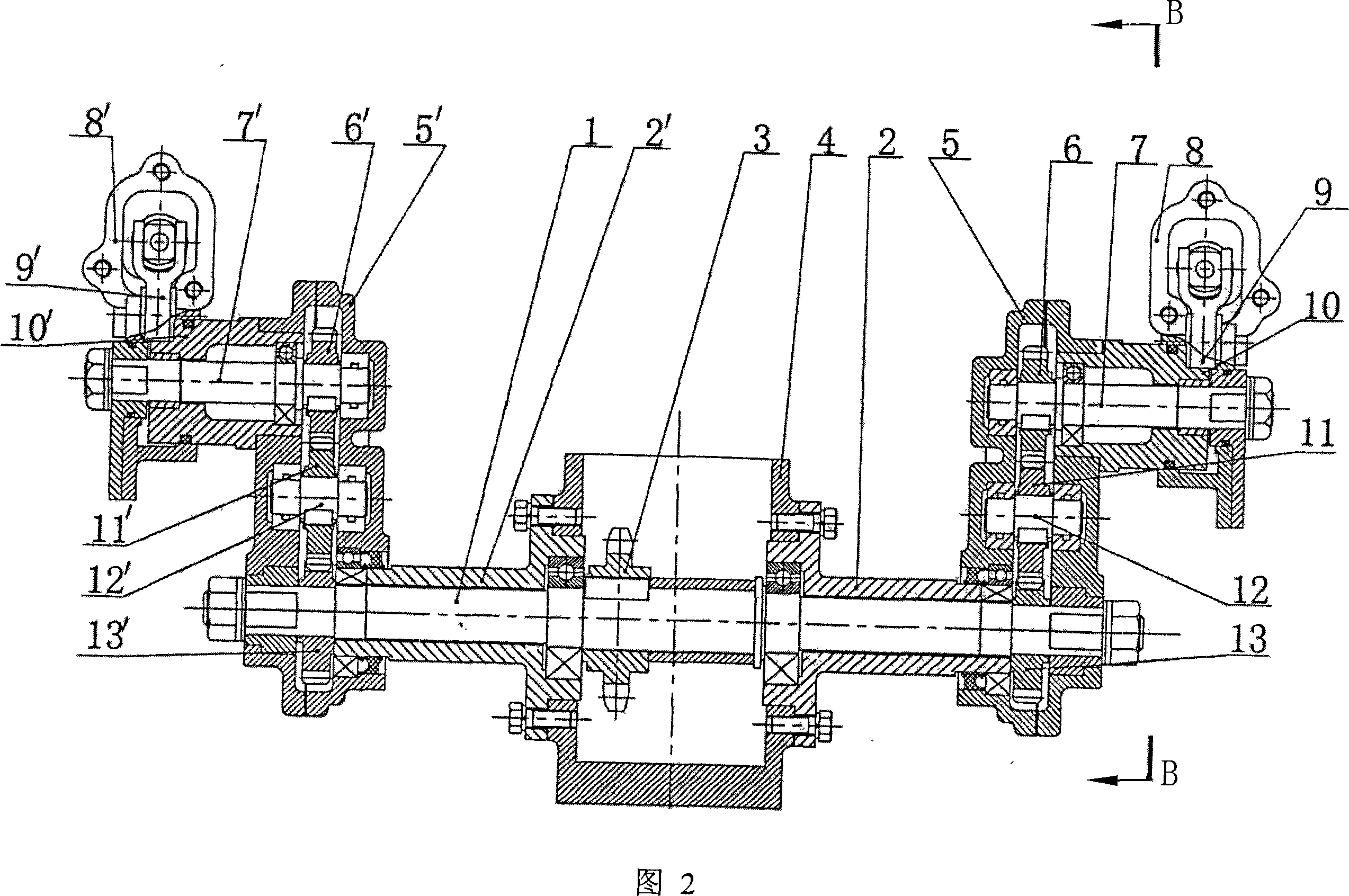

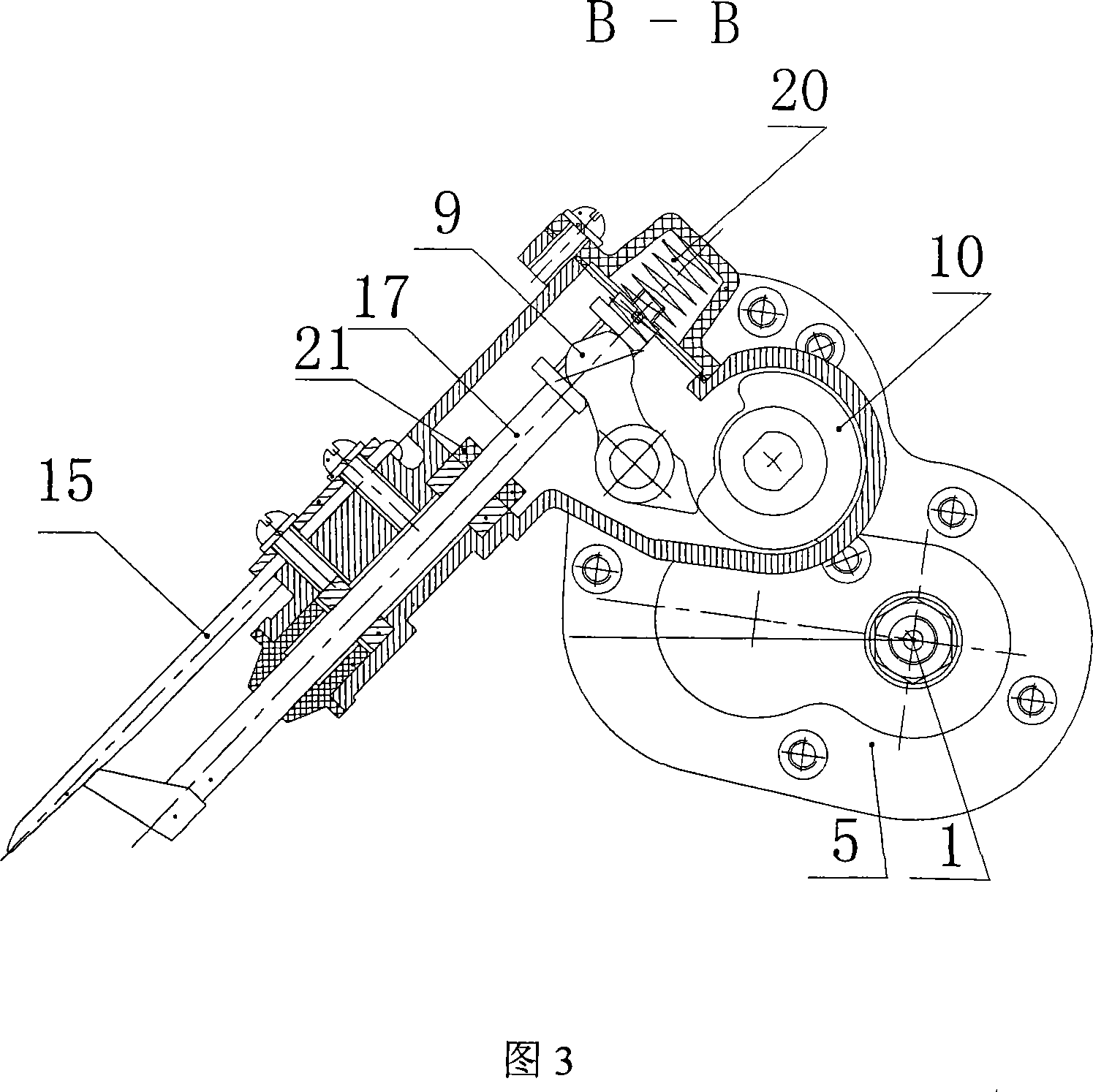

[0021] As shown in Figures 1 and 2, the offset elliptical gear of the walk-type rice transplanter of the present invention is inserted into the rotary sub-planting mechanism, which includes a transmission part and a planting arm part. The transmission parts include the transmission shaft 16 in the sprocket box 4 and the driving sprocket 18 mounted thereon, connected with the central sprocket 3 installed on the central shaft 1 in the sprocket case 4 through the chain 19, and the central shaft 1 extends Left and right gear boxes 5', 5 are respectively fixed on the shaft ends on the left and right sides outside the sprocket box 4. Left and right central gears 14', 14 fixed on the sprocket box 4 through left and right flanges 2', 2 are respectively housed on the central shaft 1 in the left and right gear boxes 5', 5, left and right 1, right center gear 14 ', 14 are fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com