Grinder dresser for gear grinding

A grinding wheel and dresser technology, which is applied in metal processing equipment, belts/chains/gears, gear teeth, etc., can solve the instability of the forming grinding process, emerald cracking into inclined planes or heterosexuality, and hinder the application of forming grinding technology and other problems to achieve the effect of eliminating blunt uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

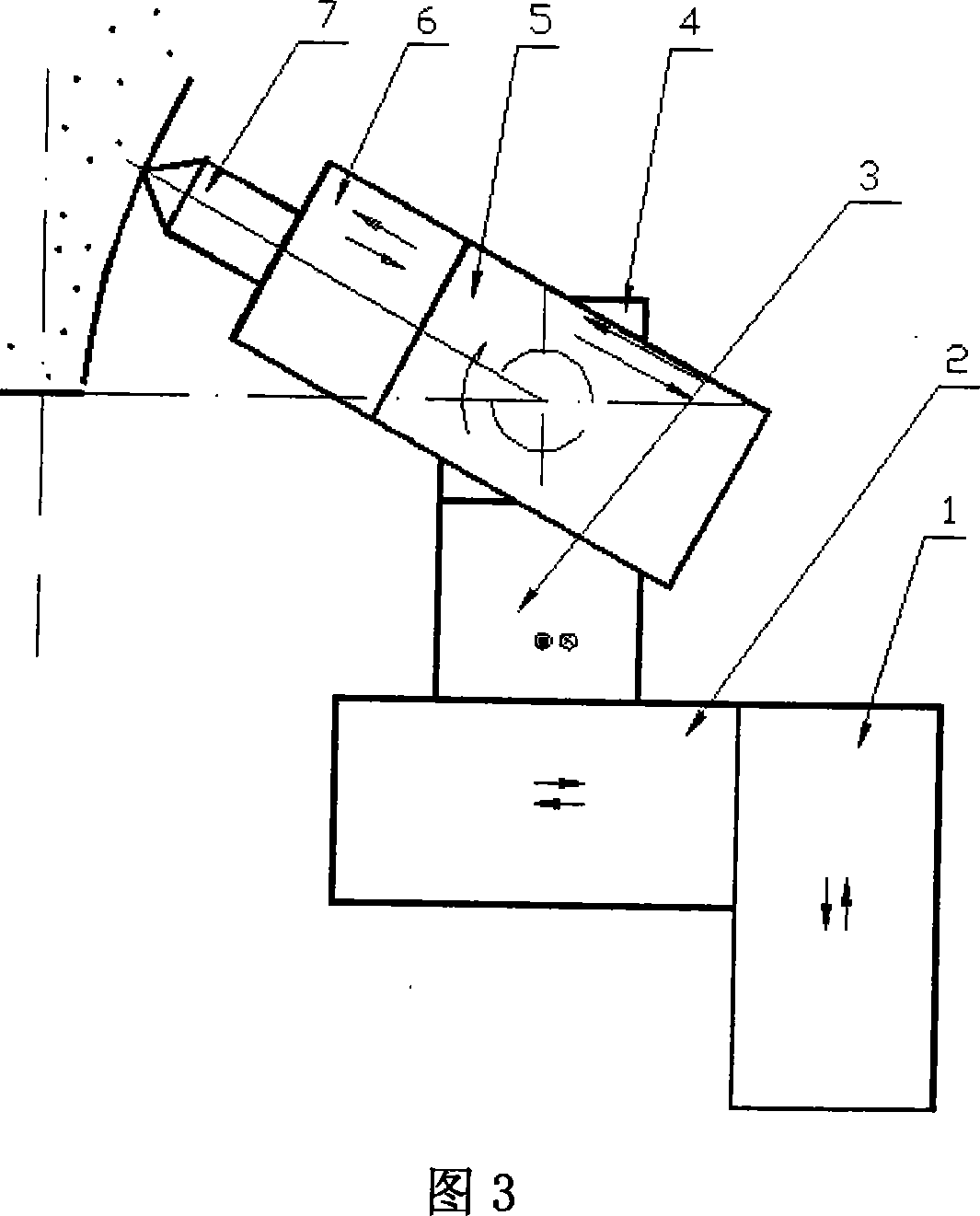

[0023] The present invention will be further explained below in conjunction with the drawings and embodiments:

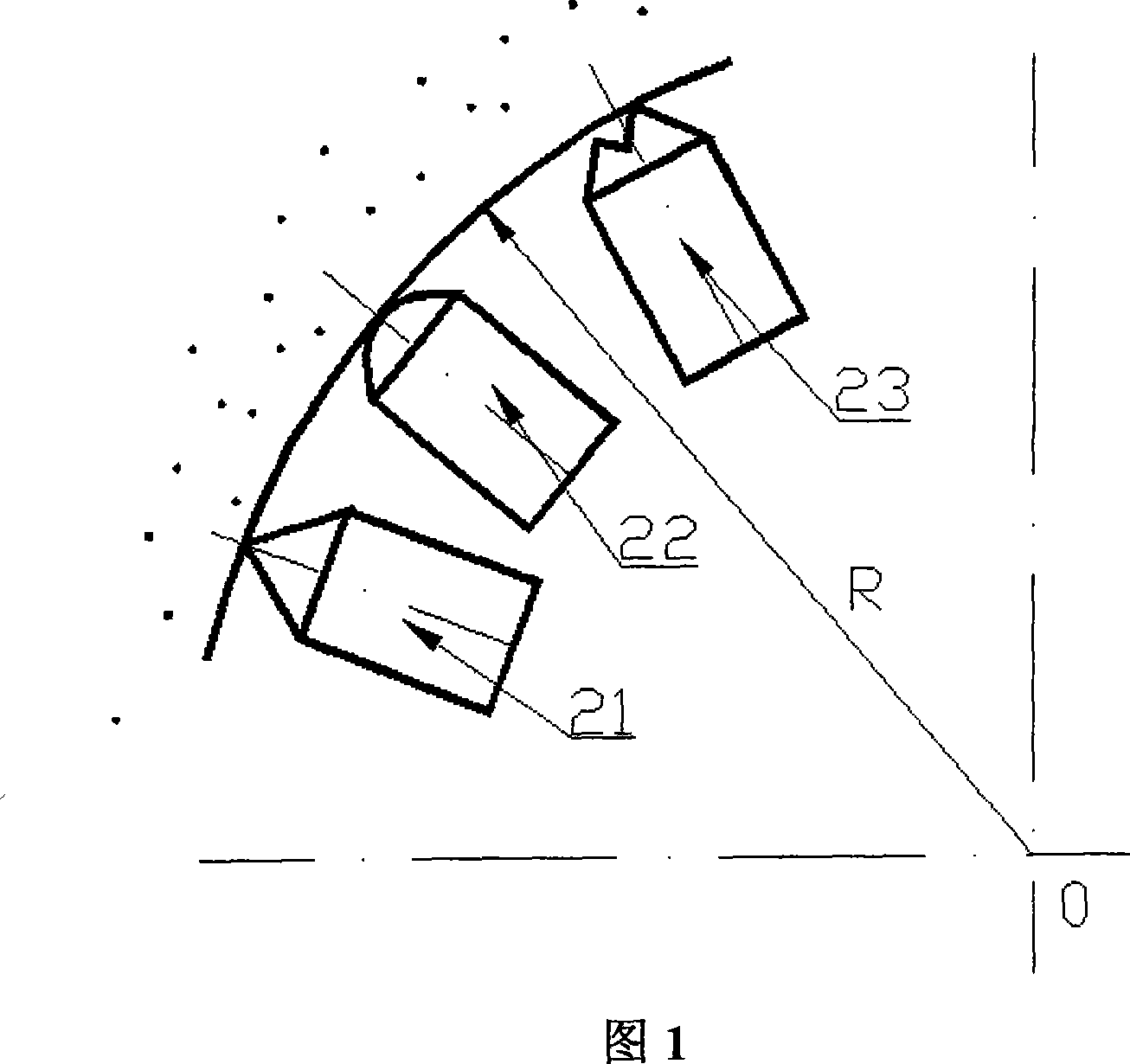

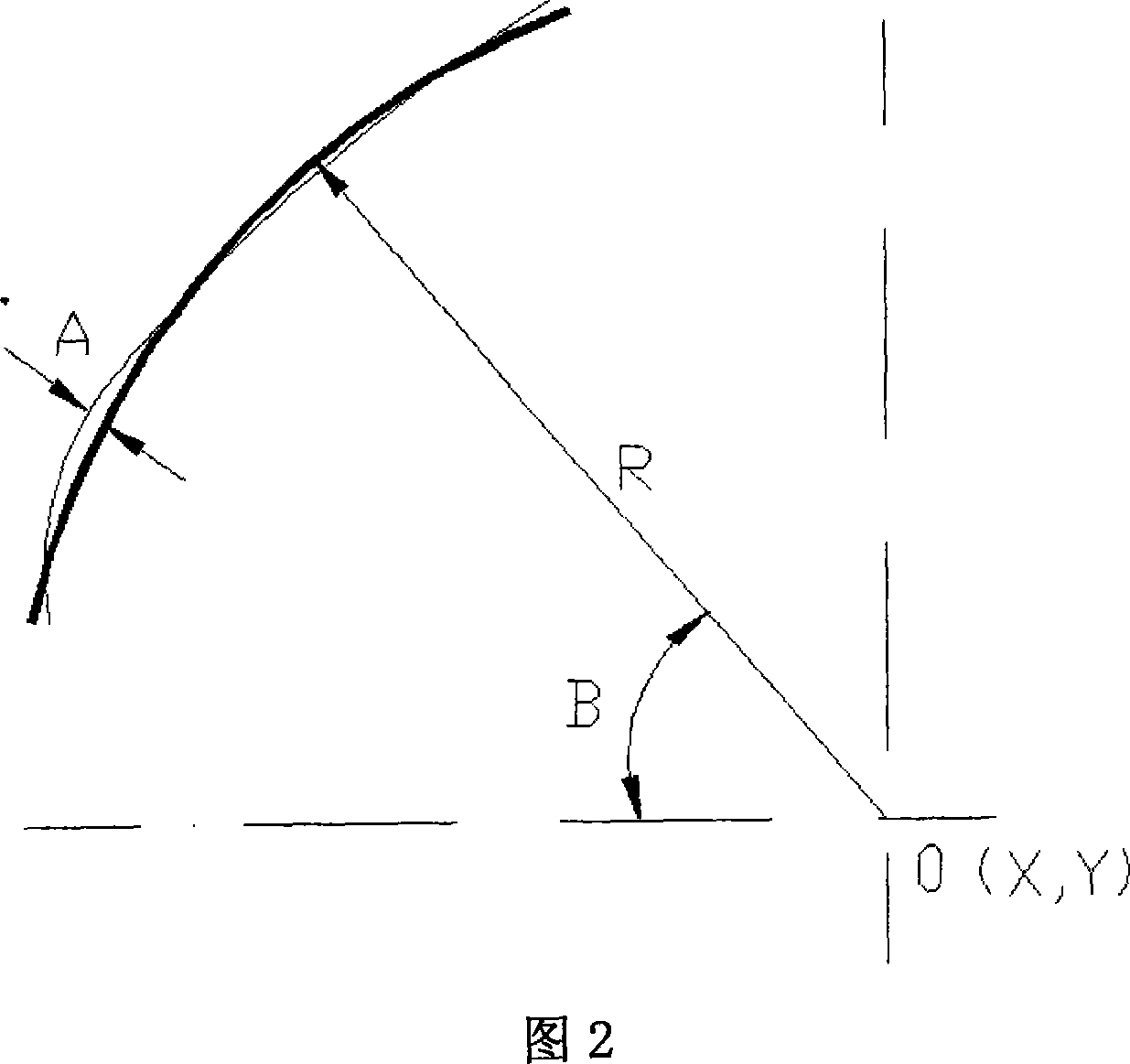

[0024] First introduce the working method. The first key problem that hinders the application of forming tooth grinding is that the diamond pen needs to be blunt by the grinding wheel during use. Because the diamond pen is a brittle material, the bluntness of the diamond nib is irregular, as shown in Figure 1. , It sometimes gradually grinds from the sharp point 21 to the arc 22. At this time, it is reflected on the gear as the length of the common normal increases; sometimes it drops to 23, which makes the highest point of the nib deviate from the center point of the diamond pen and become a multi-pointed point. At this time, when the point on the left side of the diamond nib is working, the grinding wheel is repaired to shorten the involute, and when the point on the right is working, the repaired point is to extend the involute. In most cases, it is a combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com