Environment friendly heat resistant opal crystalline glass and its preparation process

A high heat-resistant, milky white technology, applied in glass manufacturing equipment, glass furnace equipment, glass blowing, etc., can solve the problems of high investment, high cost, high price, etc., to achieve stable performance, excellent material performance, low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

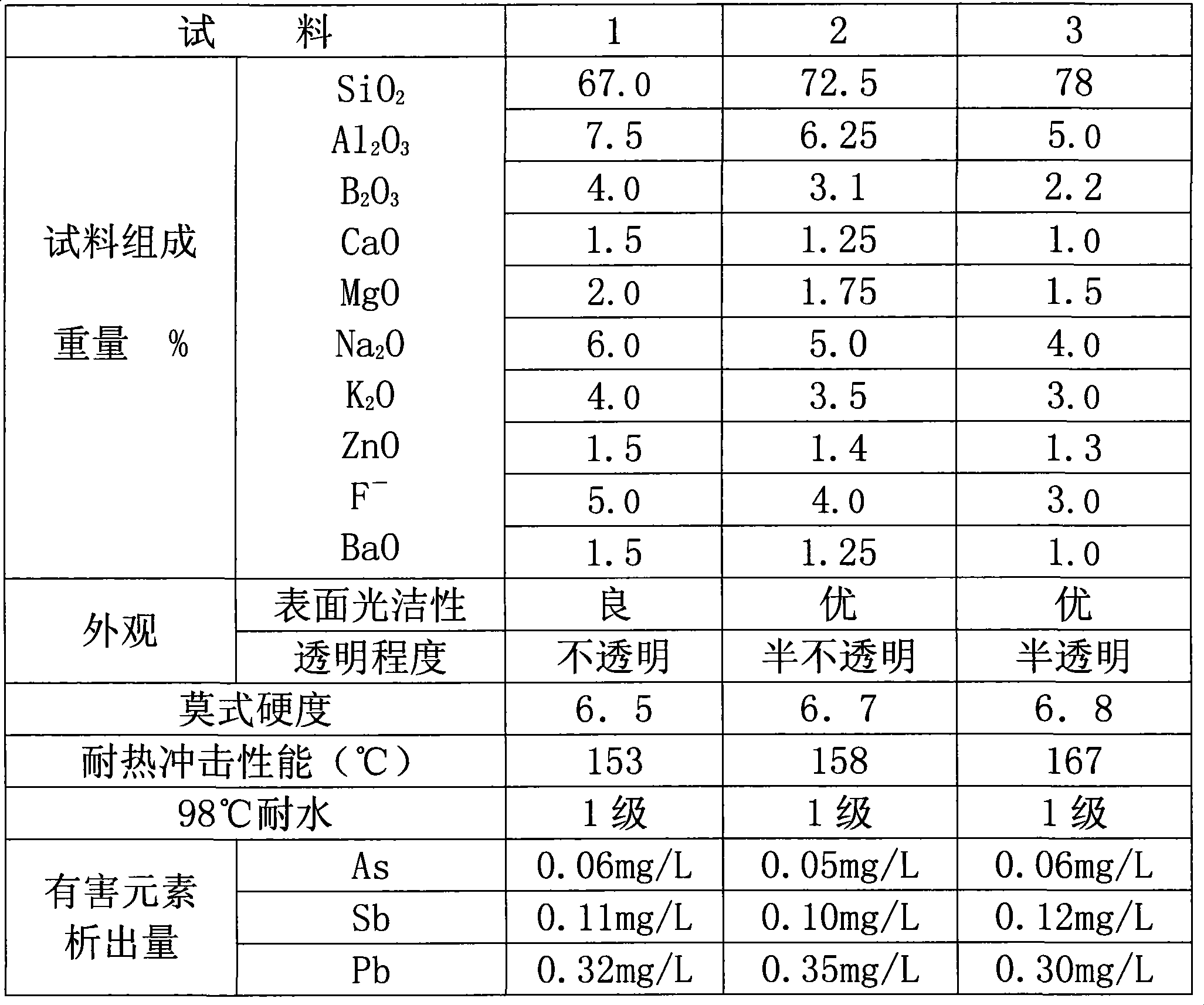

[0014] Example 1 uses waste white glass bottles as the base material, and the oxide content of each component is as follows: SiO 2 67.0%, Al 2 O 3 7.5%, B 2 O 3 4.0%, CaO1.5%, MgO2.0%, Na 2 O6.0%, K 2 O4.0%, ZnO1.5%, F - 5.0%, BaO1.5%, the ingredients are crushed to 60 mesh and mixed, the batch is uniformly mixed, and then put into the electric furnace to heat and melt. The maximum temperature of the furnace is 1480℃. The components in the batch are fully melted, homogenized and clarified. The blow molding was taken out immediately, and its appearance and physical and chemical properties were evaluated.

example 2

[0015] Example 2 uses waste white glass bottles as the base material, and the components are as follows: SiO 2 72.5%, Al 2 O 3 6.25%, B 2 O 3 3.1%, CaO1.25%, MgO1.75%, Na 2 O5.0%, K 2 O3.5%, ZnO1.4%, F - 4.0%, BaO1.25%, the ingredients are crushed to 90 mesh and mixed, the batch is uniformly mixed, and then put into an electric furnace for heating and melting. The maximum temperature of the furnace is 1500°C. The ingredients in the batch are fully melted, homogenized and clarified. Immediately take out the sample to blow molding, and evaluate its appearance and physical and chemical properties.

example 3

[0016] Example 3 uses waste white glass bottles as the base material, and the components are as follows: SiO 2 78%, Al 2 O 3 5%, B 2 O 3 2.2%, CaO1.0%, MgO1.5%, Na 2 O4.0%, K 2 O3.0%, ZnO1.3%, F - 3.0%, BaO1.0%, the ingredients are pulverized to 120 mesh and mixed, the batch is uniformly mixed, and then put into the electric furnace to heat and melt; the maximum temperature of the furnace is 1520℃, and the components in the batch are fully melted, homogenized and clarified. Immediately take out the sample to blow molding, and evaluate its appearance and physical and chemical properties.

[0017] The indexes of the opal white crystal porcelain glass obtained in the above examples 1, 2, and 3 are as follows:

[0018]

[0019] It can be seen from the data listed in the above table that the various indexes of each opal white crystal porcelain glass sample are better than those of the currently recognized good quality porcelain ware on the market, and are comparable to the expensive high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com