Permanent hot-melt electret melt-blown filtering material preparing method

A technology of filter material and manufacturing method, which is applied in the manufacturing field of permanent hot-melt electret melt-blown filter material, and can solve the problems of affecting product efficiency, broken wire, static electricity instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

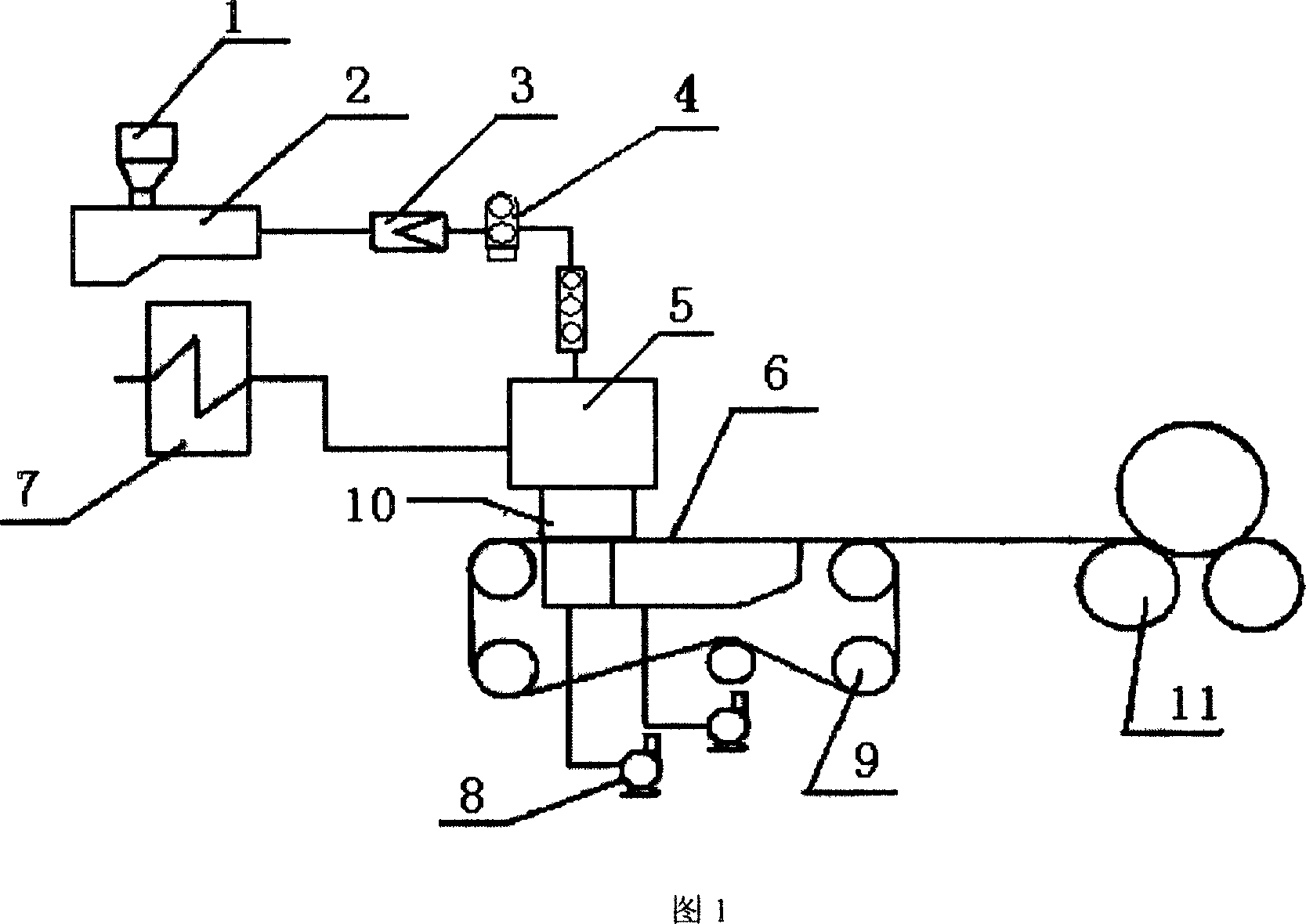

[0014] Embodiment 1: this technique comprises the steps:

[0015] (1) Mix PP melt-blown resin with a melt index of 1200-1800g / 10min with the color masterbatch and functional masterbatch through the corresponding metering device 1, and enter the screw extruder 2 after fully stirring and mixing, and heat at 275-280°C Finally, the melt is formed, and finally the melt is sent into the die head by the metering pump 4 through the pre-filter 3;

[0016] (2) The high-voltage electrostatic generator 10 applies two-pole ±10-30KV high-voltage electricity to the tip discharge device. Under the strong electric field, the air will be strongly ionized and excited locally. At this time, the speed of the hot-melt fiber is more than one kilometer The electret is completed through the discharge area, and the distance between the fiber and the tip discharge device during electret is 3-10CM.

[0017] (3) The fiber ejected from the die head 5 is flowed to 1500-3000M in a hot state 3 / H, the hot a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com