Tricot machine comb racking-movement device driven by linear servo motor

A servo motor, bar traverse technology, applied in warp knitting, textile and papermaking, knitting and other directions, can solve the problems of warp knitting machine production speed limit, reduce motion accuracy, reduce transmission efficiency and other problems, achieve pattern traverse Large scope, high input costs, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

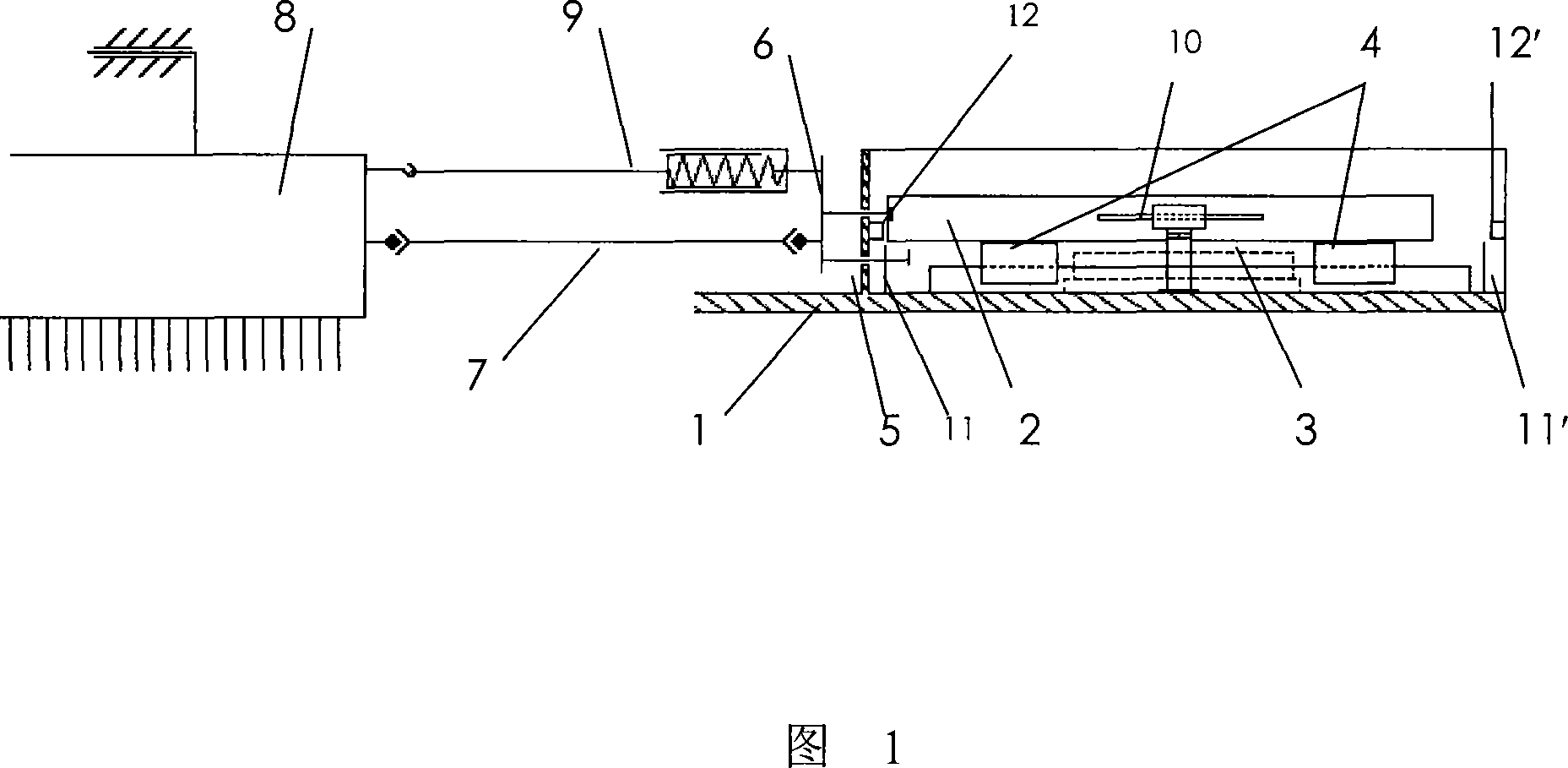

[0010] In the figure, 1 is the warp knitting machine frame (that is, the installation base of the traverse mechanism), 2 is the flat linear servo motor mover (coil or magnetic steel can be used), and 3 is the flat linear servo motor stator (coil or magnetic steel Both can be used, such as 2 is a coil, then 3 is a magnetic steel), 4 is a flat linear servo motor mover slide rail and base, 5 is a traverse guide rod, 6 is a movement connecting rod, 7 is a support rod, 8 is a Knitting machine bar, 9 is the tension steel wire, 10 is the grating for feedback, 11, 11' is the two limit proximity switches on the left and right, 12, 12' are the two mechanical limit blocks on the left and right, 13 is the push rod, 14 is spring.

[0011] As shown in the figure: the flat linear servo motor stator 3 is installed on the warp knitting machine frame 1, and the flat linear servo motor mover 2 that can move left and right relative to the flat linear servo motor stator 3 is installed on the flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com