Mechanism for measuring dynamic strength of automobile front axle rocker arm

A technology of dynamic strength and front axle, which is applied in elastic testing, vehicle testing, machine/structural component testing, etc. It can solve the problems of large loss of test parts and the inability to simulate the actual working conditions of the front axle rocker arm of the car, etc., to achieve Credibility-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

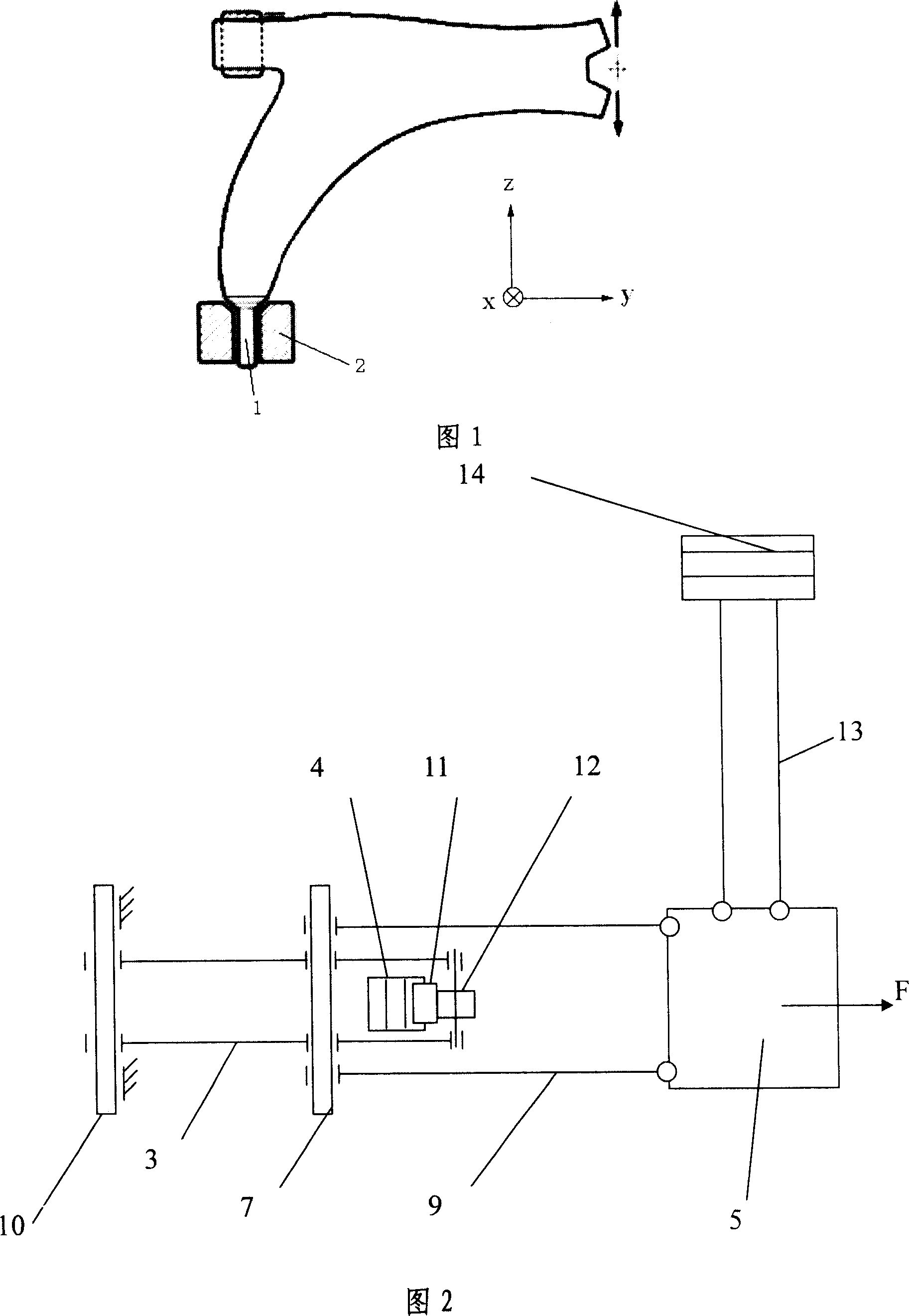

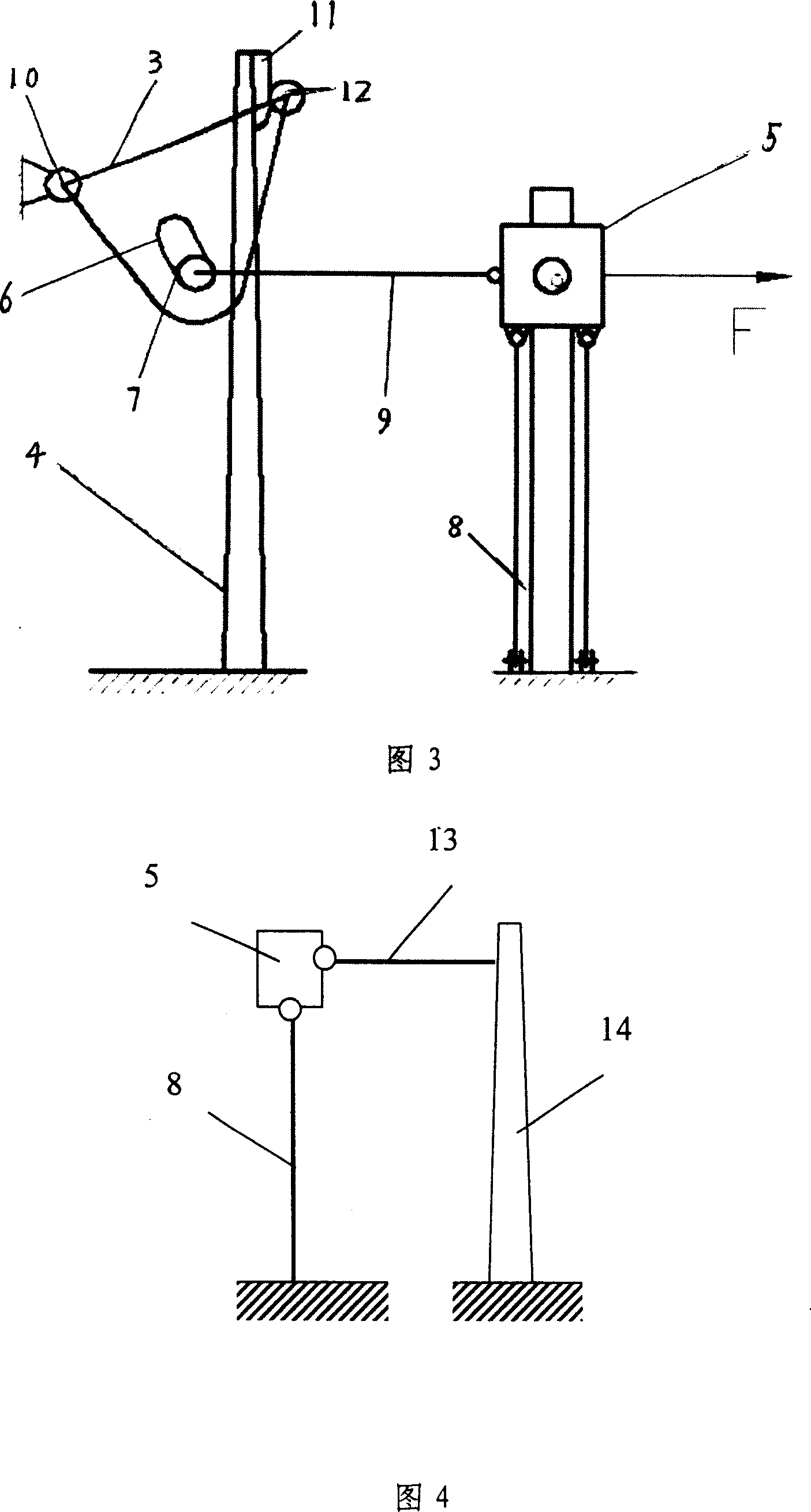

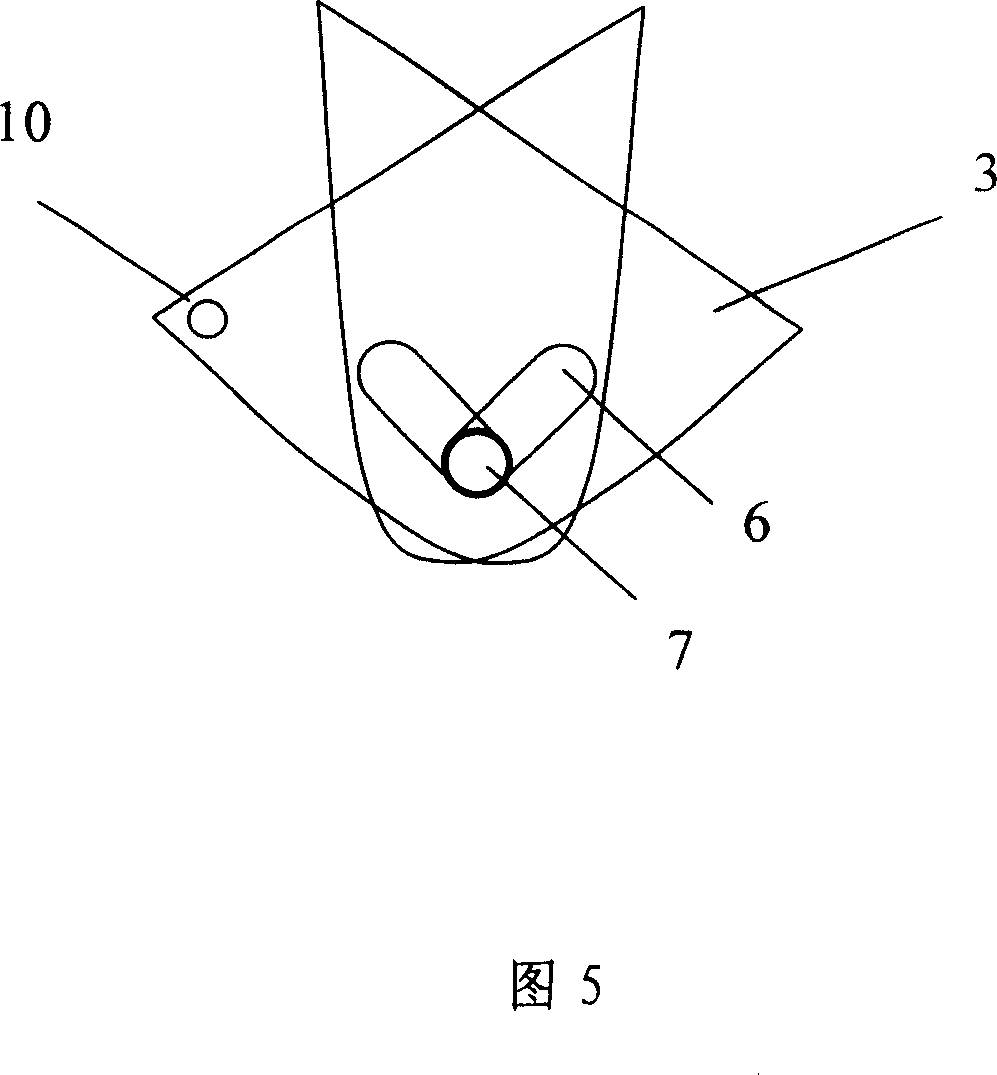

[0015] As shown in Fig. 1, in the dynamic durability bench test carried out on the rocker arm of the front axle of the automobile in the prior art, the rubber metal bearing 2 at the rear shaft support 1 of the rocker arm occurred abnormal early damage. Dozens or even more rubber-metal bearings 2 need to be lost to complete the test. For this reason, the test mode has been changed, that is, the rocker arm rear axle support 1 is directly fixed in a rigid frame. However, during the test, it was found that there was abnormal damage near the rear axle of the rocker arm, and the service life was very short. The reason is that the rubber-metal bearing 2 is changed to a rigid support, which changes the constraints or boundary conditions of the rocker arm, thus destroying the deformation distribution and stress distribution of each point of the rocker arm when it is stressed.

[0016] According to the similarity theory, any two points of the rocker arm installed on the vehicle (assume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com