Deep-sea piezoelectric underwater-acoustic transducer and its manufacturing method

A technology for underwater acoustic transducers and manufacturing methods, applied to piezoelectric/electrostrictive transducers, transducers for underwater use, piezoelectric/electrostrictive/magnetostrictive devices, etc., capable of solving work problems Problems such as small depth, inability to have broadband and semi-space directivity at the same time, low hydrostatic pressure resistance, etc., to achieve the effects of high hydrostatic pressure resistance, avoiding oil-filled process equipment, and high hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

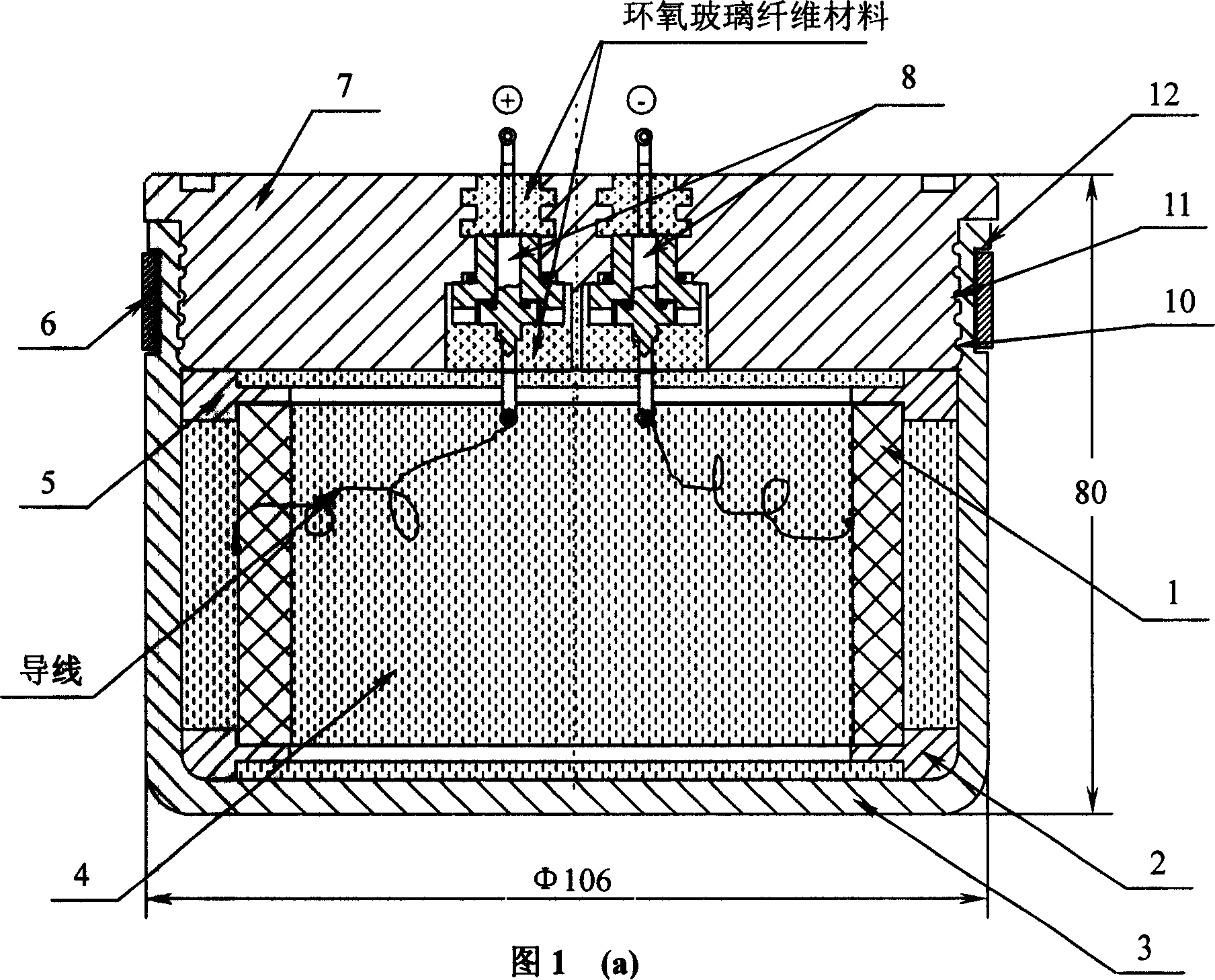

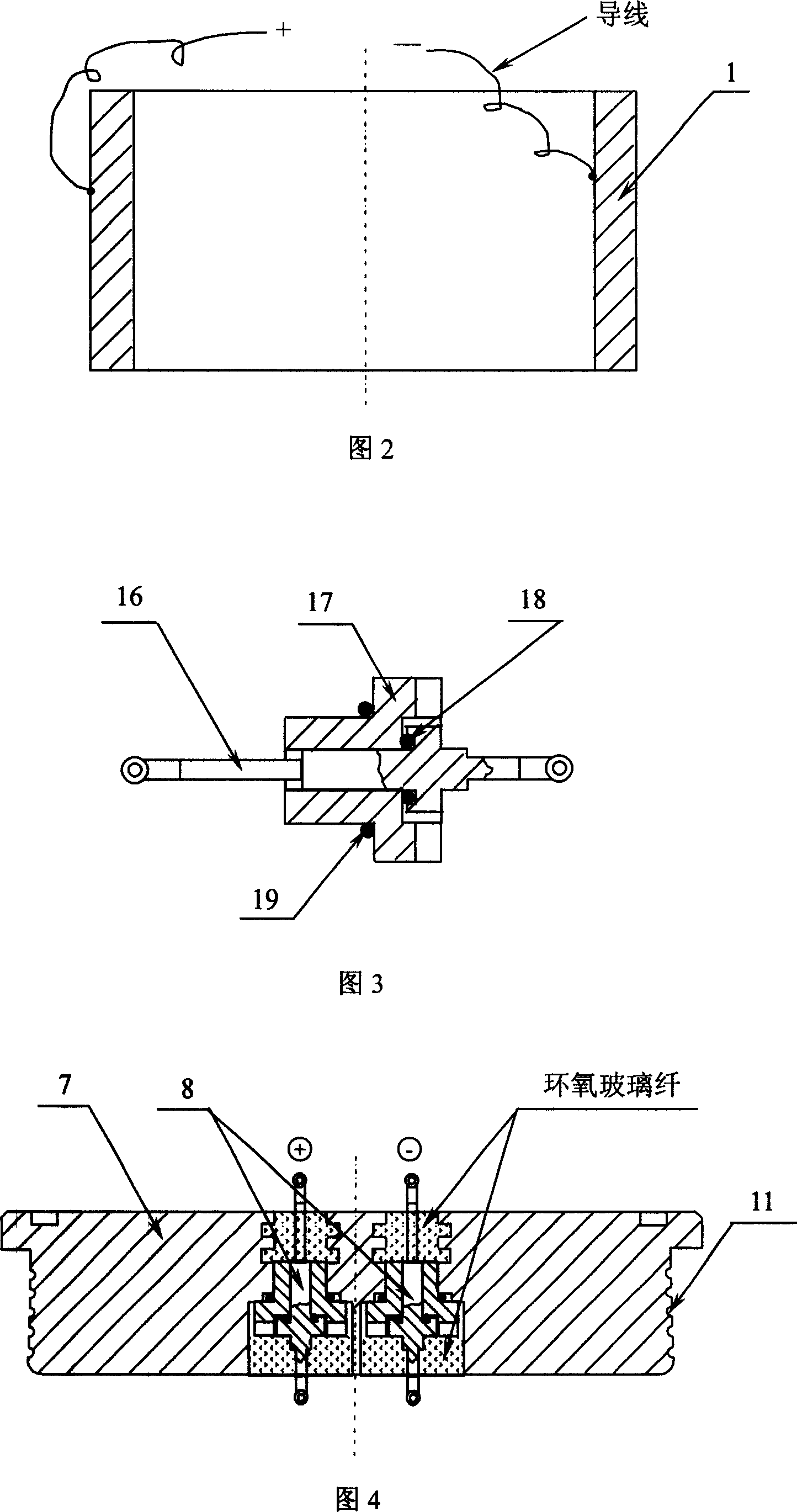

[0047] A schematic diagram of the implementation structure of a specific deep-sea piezoelectric underwater acoustic transducer of the present invention is given in FIG. 1 . It consists of piezoelectric ceramic round tube 1, upper support frame 2, lower support frame 5, sealed sound-permeable rubber oil bag 3, silicone oil 4, snap ring 6, support base 7, electrode output socket 8 (specifically as shown in Figure 3) and oil nozzle 9 (specifically as shown in Figure 1(c), Figure 5) and other components.

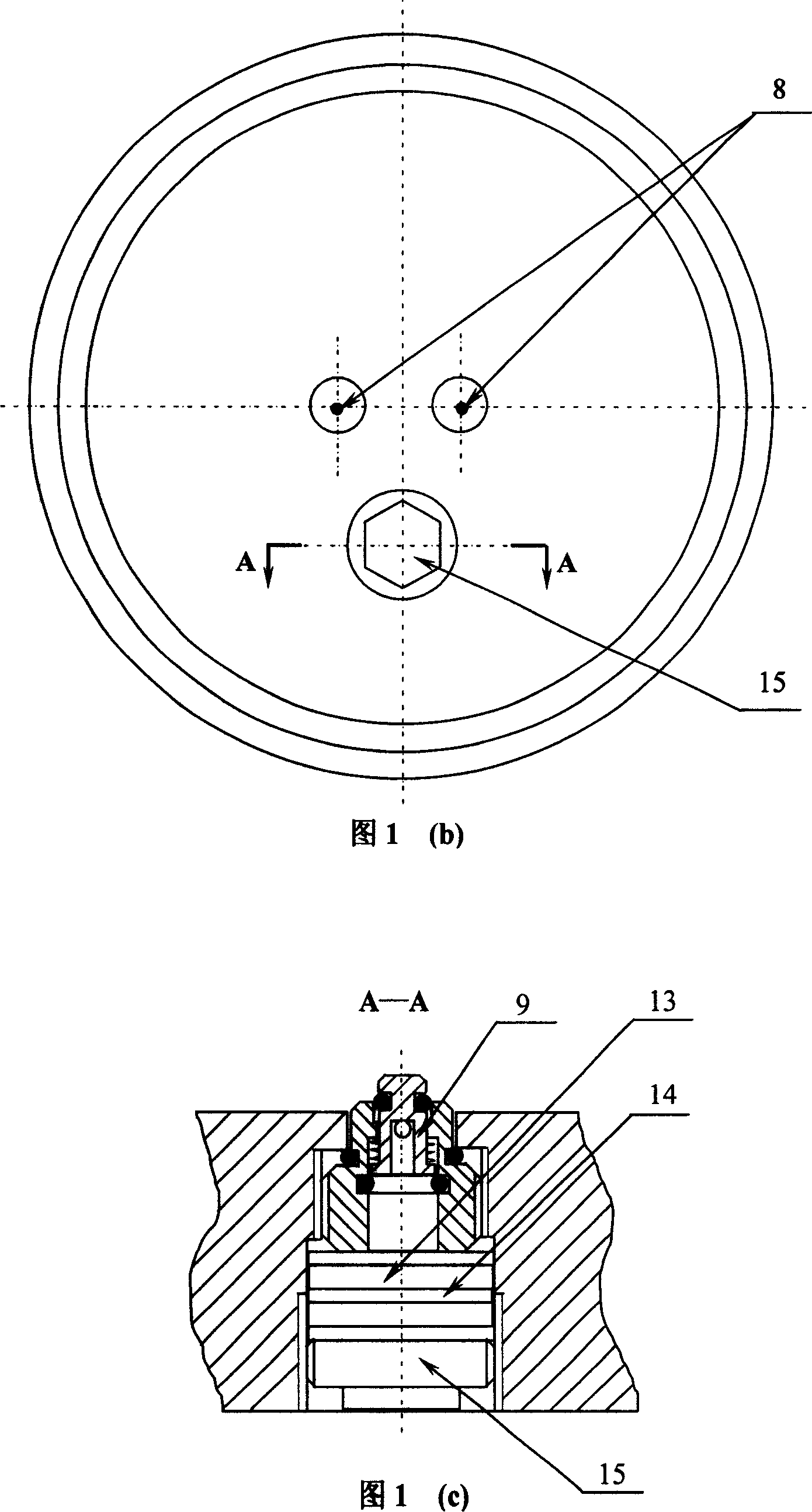

[0048] The piezoelectric ceramic circular tube 1 shown in Figure 2 is one of the key components of the transducer. It is a radially polarized circular tube structure made of PZT-4 piezoelectric ceramic material. The outer wall is the positive pole and the inner wall is the negative pole. Size determines the performance of the final transducer. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com