Device for drying sheet of paper used for single sheet paper printing machine

A printing press, sheet-fed technology, applied in the general parts of printing machinery, printing press, drying gas arrangement, etc., can solve problems such as unimprovable efficiency, achieve good efficiency, structure optimization, and avoid warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

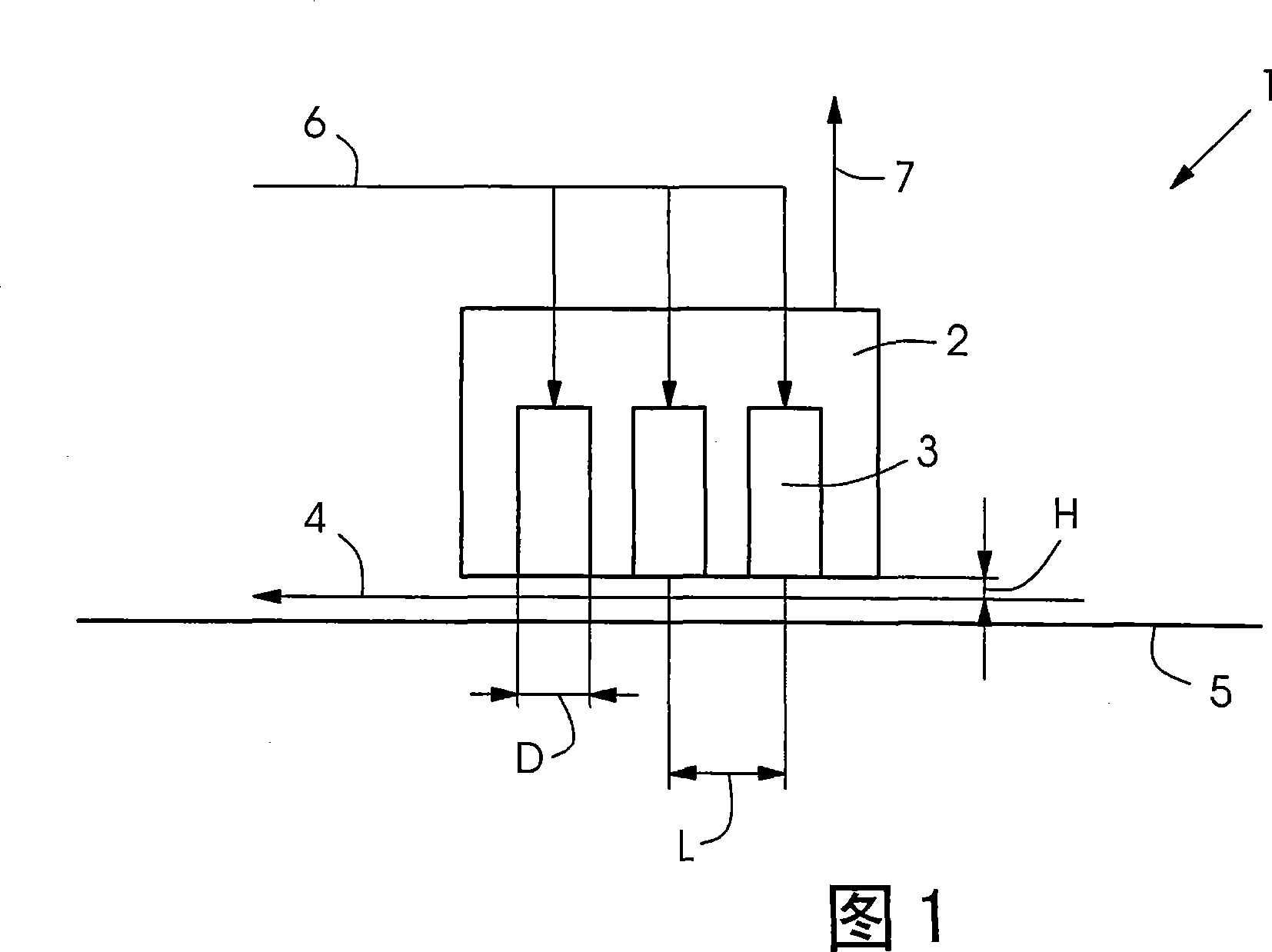

[0019] The single figure shows a detail of the sheet-fed printing press 1 . The sheet-fed printing press 1 comprises a hot air dryer 2 with nozzles 3 arranged in a grid. The sheets 4 conveyed past the hot air dryer 2 by means of the conveying device 5 or the printing ink lying thereon are dried by the hot air expelled from the nozzles 3 .

[0020] The transport device 5 is a conveyor belt or alternatively also a cylinder of the printing press 1 , for example an impression cylinder. The conveying device 5 conveys the sheets in the direction of sheet travel, which is symbolically indicated by an arrow in the figure.

[0021] The nozzle 3 is connected to the hot air supply device 6, after the hot air discharged by the nozzle 3 impinges on the sheet 4 and part of the heat of the hot air is released to the sheet, this hot air is sucked by the suction device 7 out. The nozzle 3 is designed as a so-called round nozzle with circular nozzle openings which determine the outflow diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com