Composite hot pipe and its production

A manufacturing method and composite technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as low yield rate, poor heat dissipation effect of electronic components, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

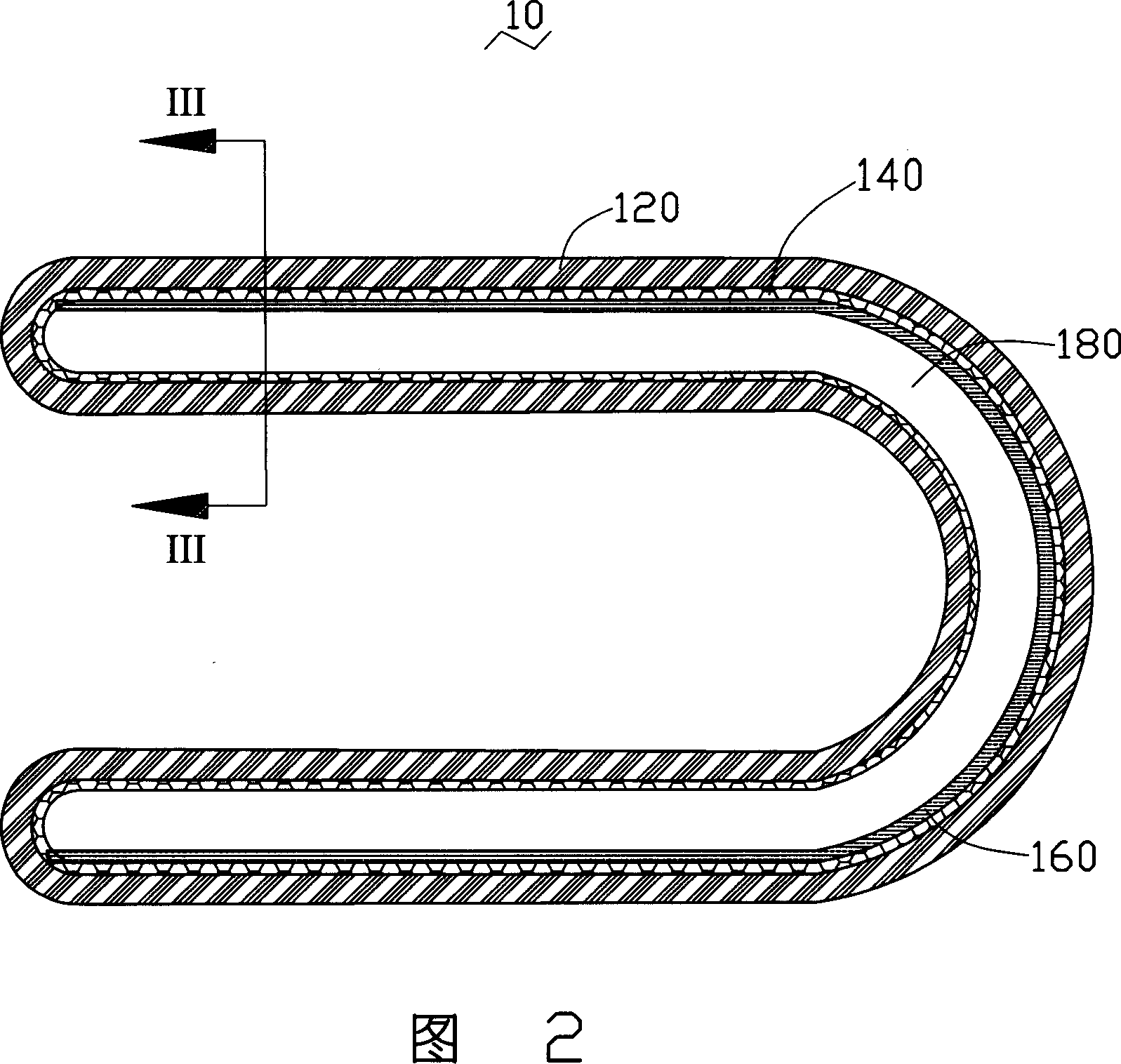

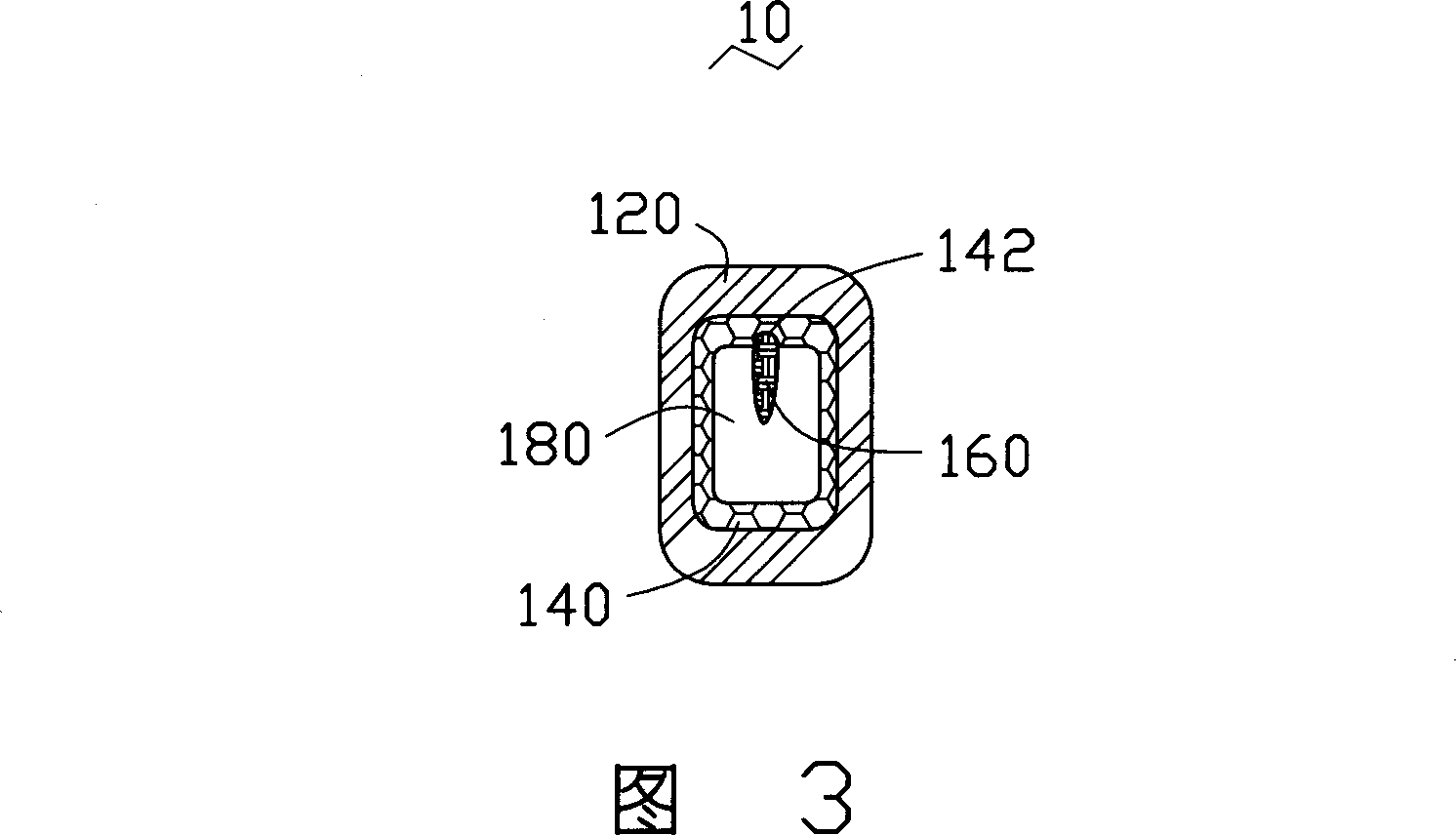

[0018] Please refer to FIG. 2 and FIG. 3 , which are longitudinal and transverse cross-sectional views of a composite heat pipe 10 according to an embodiment of the present invention. The heat pipe 10 is bent in a U shape, and its transverse section is rectangular. The heat pipe 10 includes a hollow shell 120, and a sintered first capillary structure 140 is attached to the inner wall of the hollow shell 120. The first capillary structure 140 in the heat pipe 10 is A groove 142 along the extension direction of the heat pipe 10 is provided on the inner surface close to the outer bend of the tube. A fibrous second capillary structure 160 is accommodated in the groove 142 and integrated with the first capillary structure 140 . At the same time, the center of the heat pipe 10 is surrounded by the inner surfaces of the capillary structures 140 and 160 to form a steam flow channel 180 arranged along the extending direction of the heat pipe 10, which contains a proper amount of working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com