Connector between high-temperature superconductive magnet double-cake coils and its welding method

A double-cake coil, high-temperature superconducting technology, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of welding point damage, difficult temperature control, large difference in joint resistance, and reduce operating costs. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

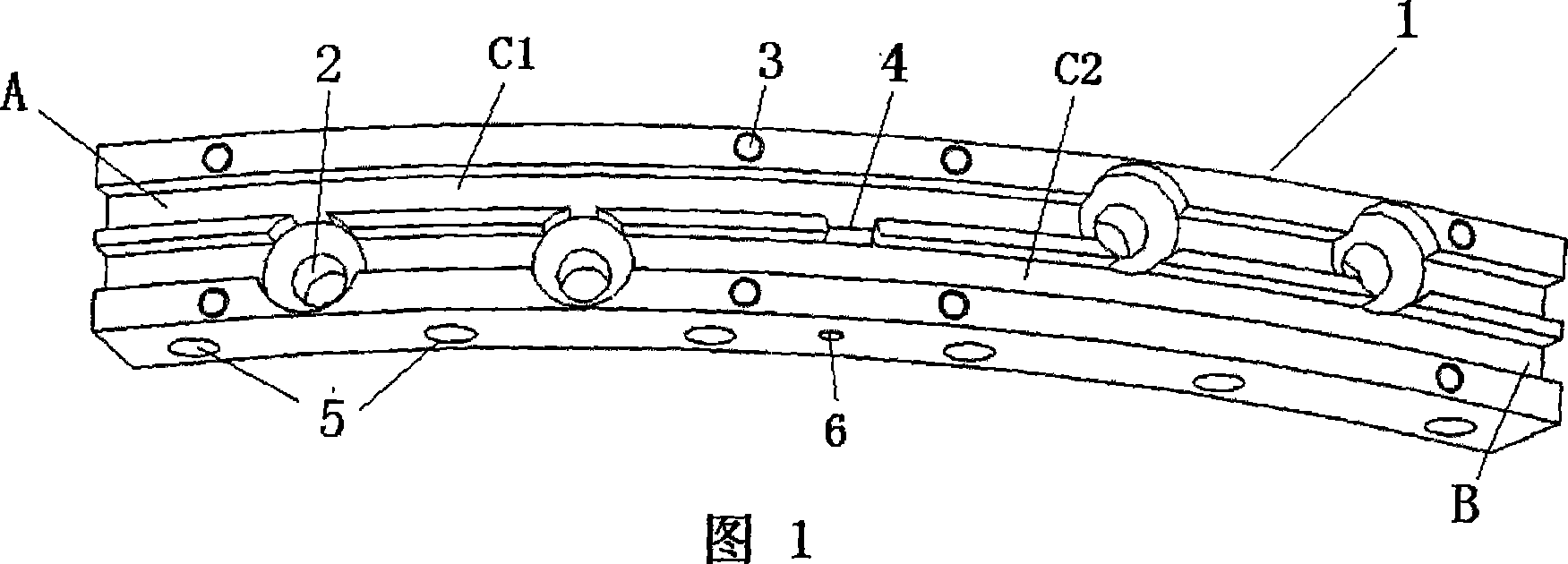

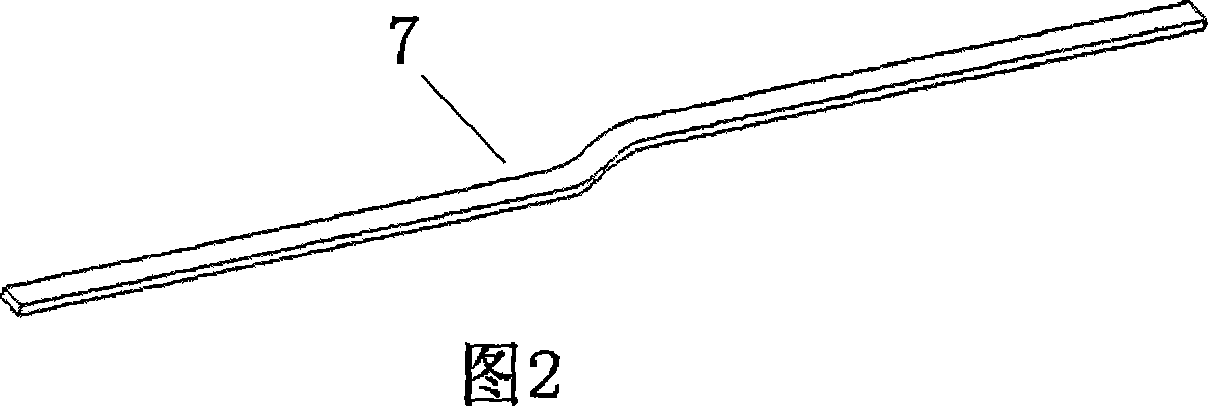

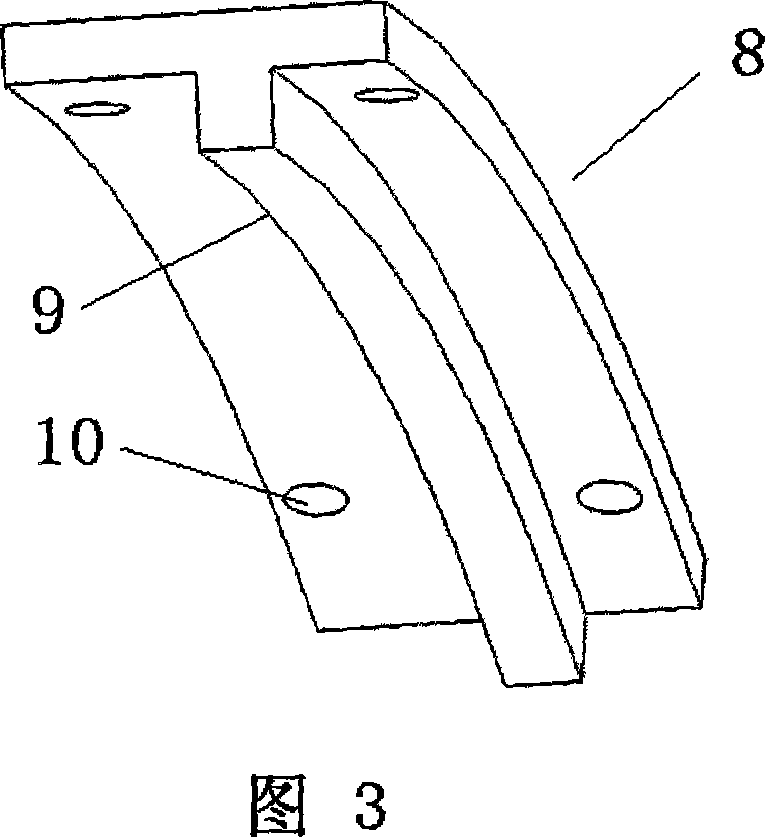

[0023] The present invention is mainly composed of a concave substrate 1, a NbTi bridge 7, a convex cover 8 and the like. As shown in Figure 1, the concave substrate 1 is fixed on the magnet, which is the joint body, the NbTi bridge 7 is embedded in the concave grooves C1 and C2 on the substrate 1, and the convex beam 9 of the convex cover 8 is snapped into the substrate 1 Press and fix the NbTi bridge 7 in the concave grooves C1 and C2 on the top. Concave substrate 1 is about 10-25cm long, is twice of the lap welding length of common superconducting tape, and is an arc-shaped body processed by low-resistivity metals such as red copper, and is the main part of the present invention. The width of the concave groove C1, C2 is slightly wider than the width of the high temperature superconducting tape 11 and 12 used by the double cake coil D1, D2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com