Clutch

A clutch and clutch device technology, applied in the field of clutches, can solve problems such as threats, complicated actuator technology, and large space, and achieve the effect of reducing axial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

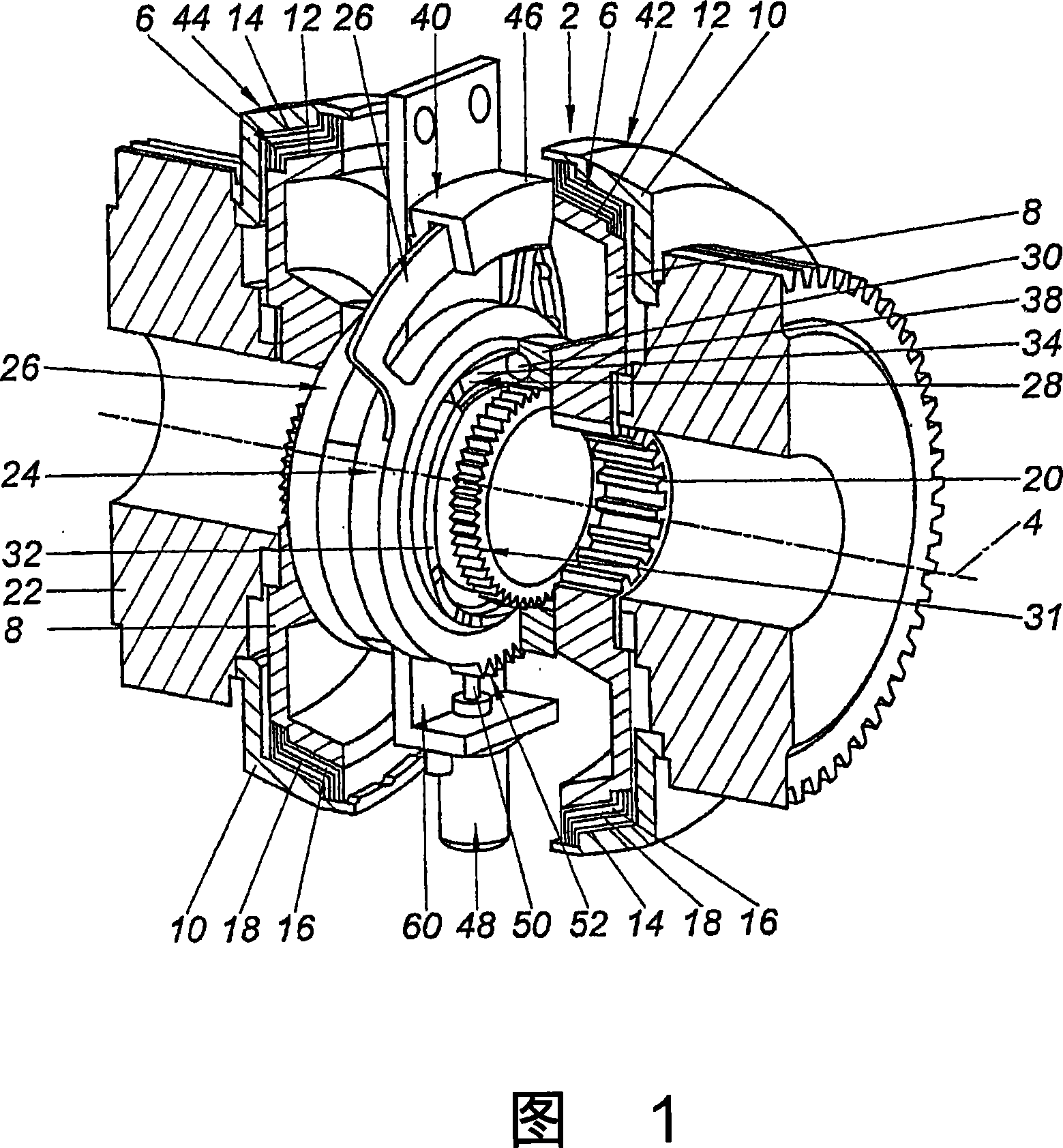

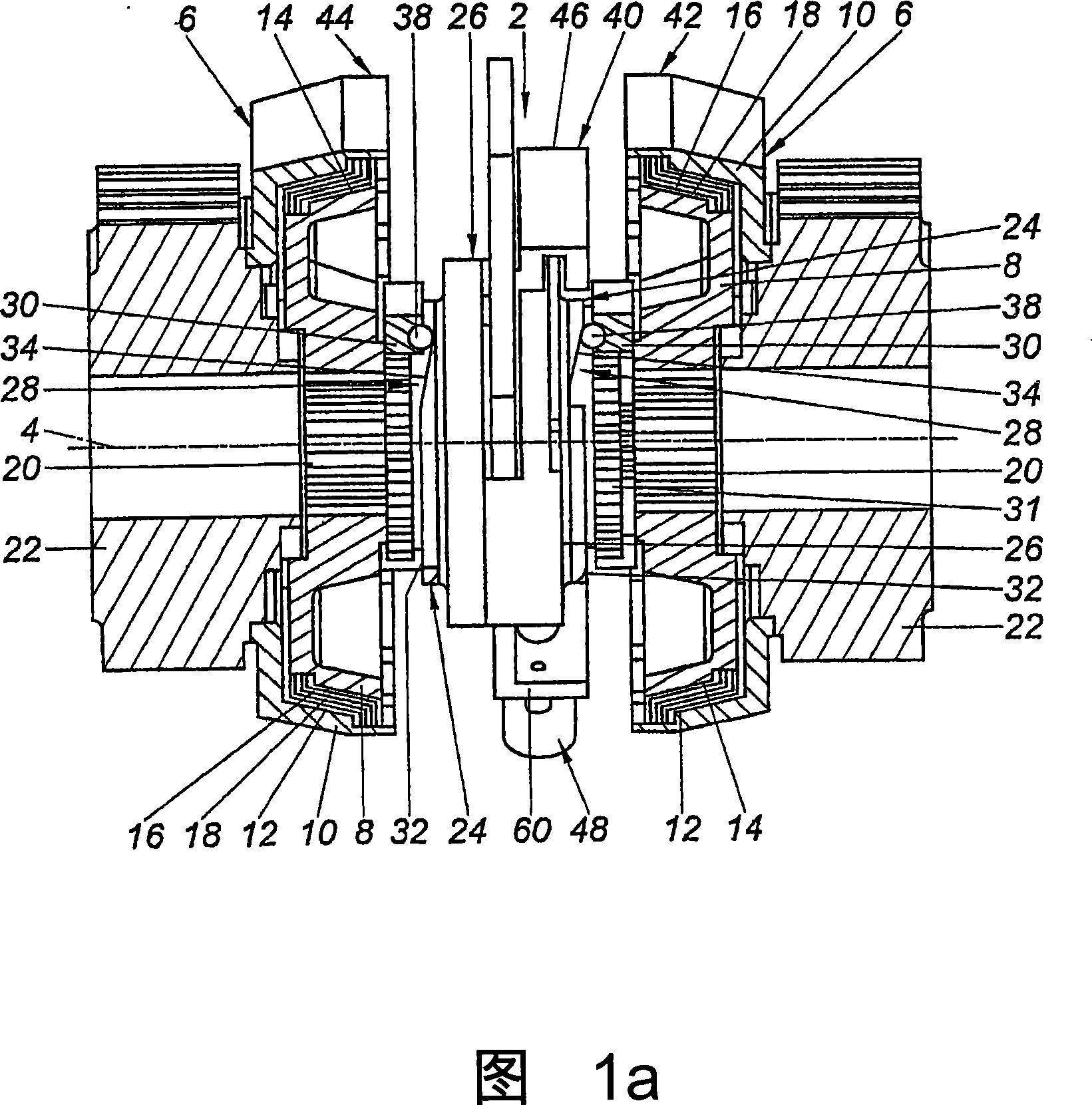

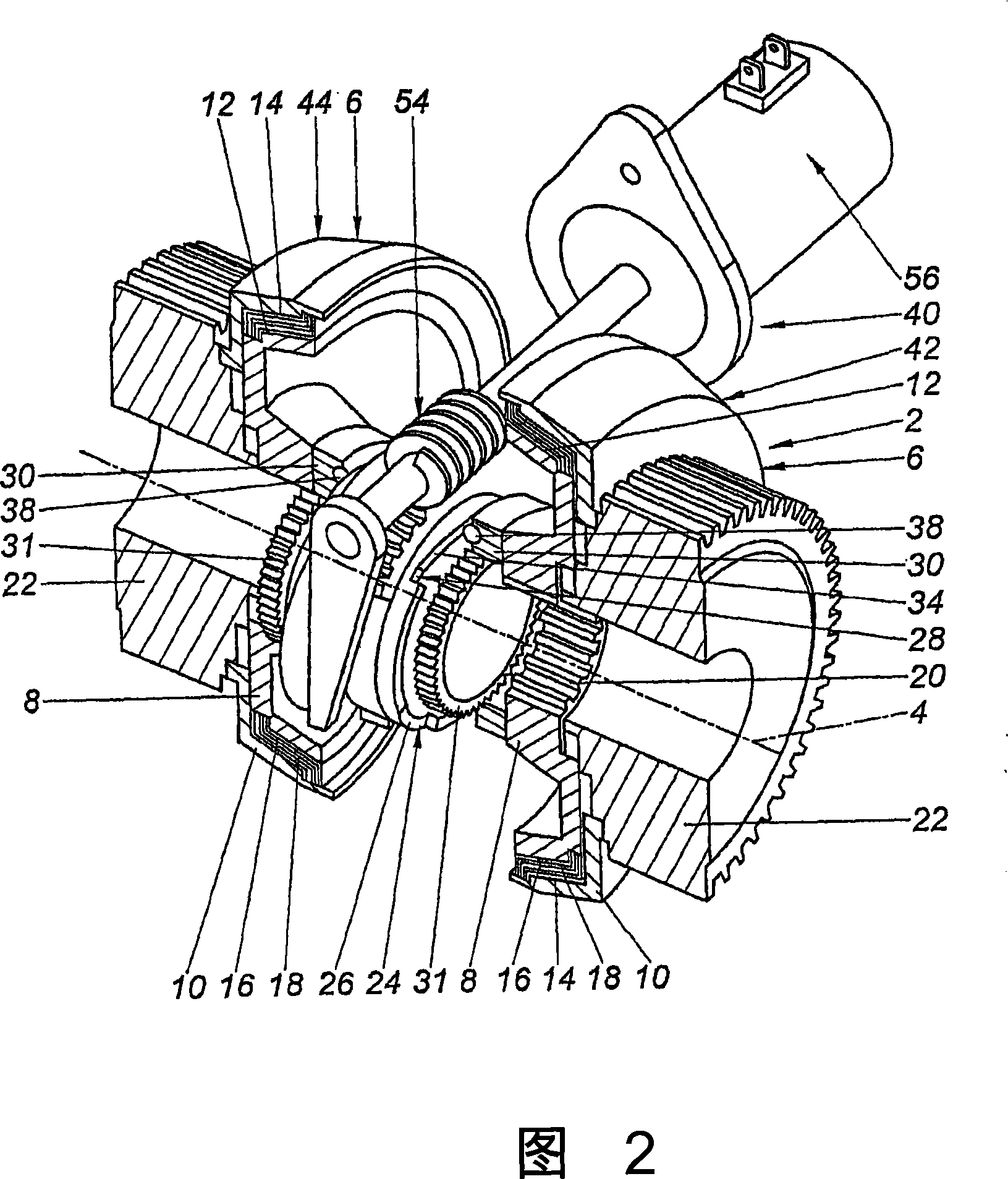

[0025] Parts with the same function are shown with the same reference numerals in the embodiments.

[0026] The clutch 2 serves for the rotational connection of at least two drive parts rotating about an axis of rotation 4 . The clutch 2 comprises at least one clutch device 6 with a first clutch body 8 and a second clutch body 10 such that the first clutch body 8 forms at least one first clutch surface 12 and the second clutch body 10 forms at least one second clutch body 10. clutch surface 14 . In various embodiments, the clutch device 6 is arranged as a multi-cone disc clutch such that the mutually facing first and second clutch surfaces 12, 14 have a conical shape. The disc bodies 16, 18 are arranged between the first and second clutch surfaces 12, 14, alternately with each first disc body 16 being rotatably connected to the first clutch body 8 and the second disc body 18 being connected to the second The clutch body 10 is maintained in an axially movable manner. Multi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com