Magnesium alloy anti-balloon plate

A magnesium alloy and yarn separator technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of low processing precision, short service life, and poor strength of parts, and improve processing Accuracy, lower production cost, bright and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

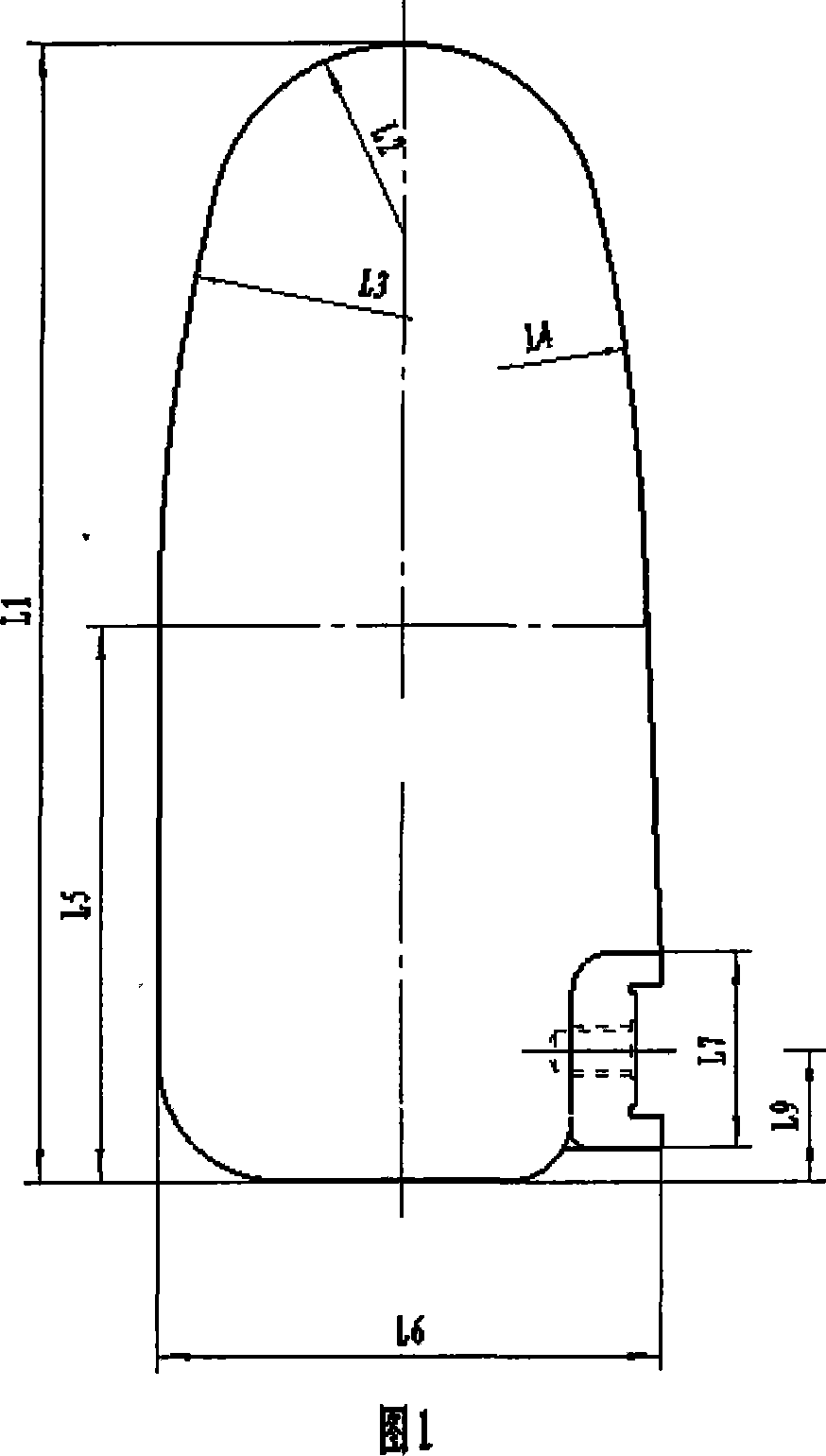

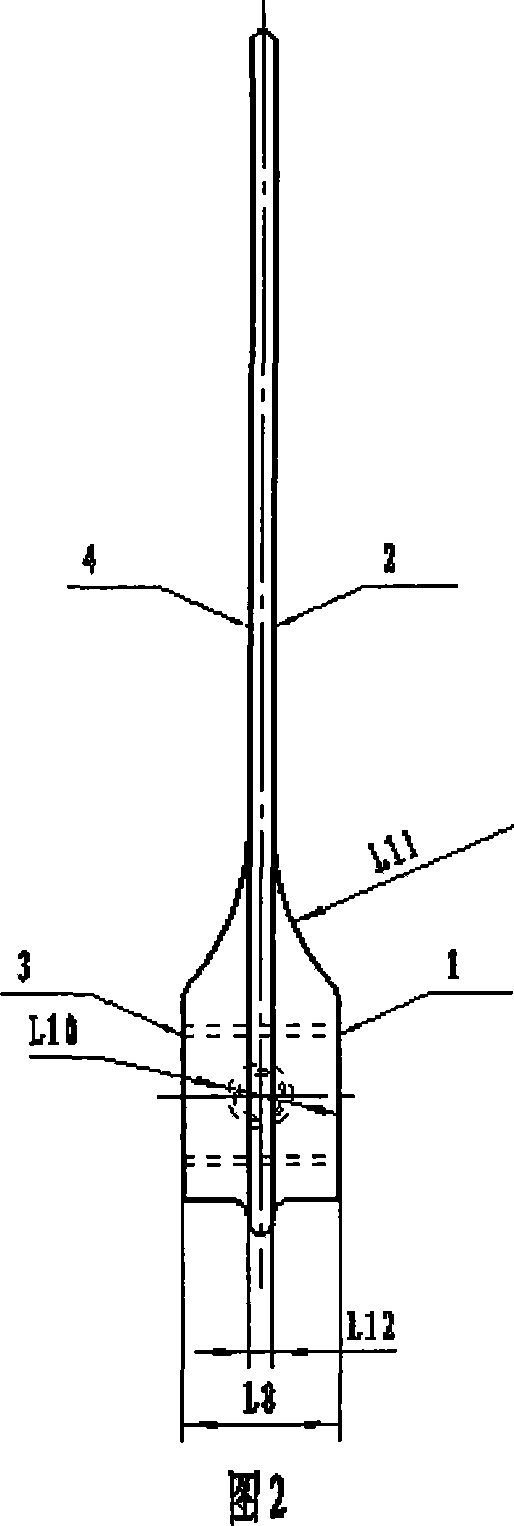

[0007] The total height L1 of the magnesium alloy spacer is 140 mm, the upper part is an ellipse formed by three arcs with a radius L2 of 24 mm, a radius L3 of 219 mm, and a radius L4 of 219 mm, and the lower part has a length L5 of 68 mm, width L6 is a rectangle of 62 mm, the lower right corner is a rectangular installation boss with length L7 of 24 mm and width L8 of 18 mm, and a M6 mm threaded hole L10 is set in the center of the rectangular installation boss. The distance between the center of the center and the lower edge L9 is 16 mm, and the arc transition between the surface 1 and the surface 2, the surface 3 and the surface 4 is 28 mm in radius L11, and the thickness L12 between the surface 2 and the surface 4 is 2 mm. Magnesium alloy The material of the spacer is magnesium aluminum alloy AZ91D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com