Film forming device, film forming method, and method of producing organic el element

A film-forming device and film-forming method technology, applied in the direction of electrical components, electroluminescent light sources, semiconductor/solid-state device manufacturing, etc., can solve the problems of not being able to obtain film-forming patterns, spend manufacturing time, and waste time, and achieve shortened production Interval time, shortened manufacturing time, effect of shortened manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

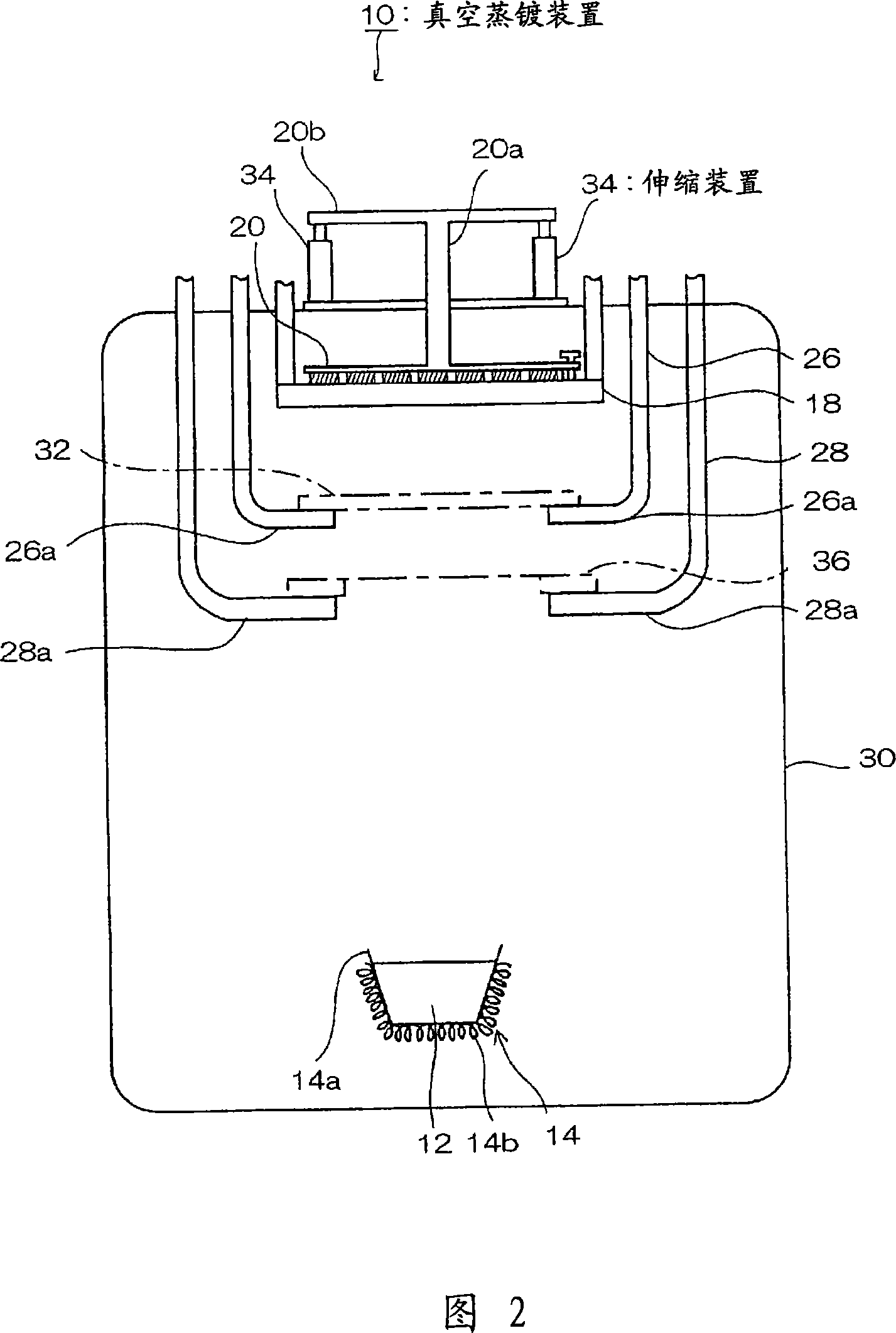

[0035] Next, preferred embodiments of the film forming apparatus, film forming method, and method for manufacturing an organic EL (electroluminescence) element of the present invention will be described. In addition, in this embodiment, a mode in which an organic EL element is manufactured using a vacuum vapor deposition device as a film forming device will be described.

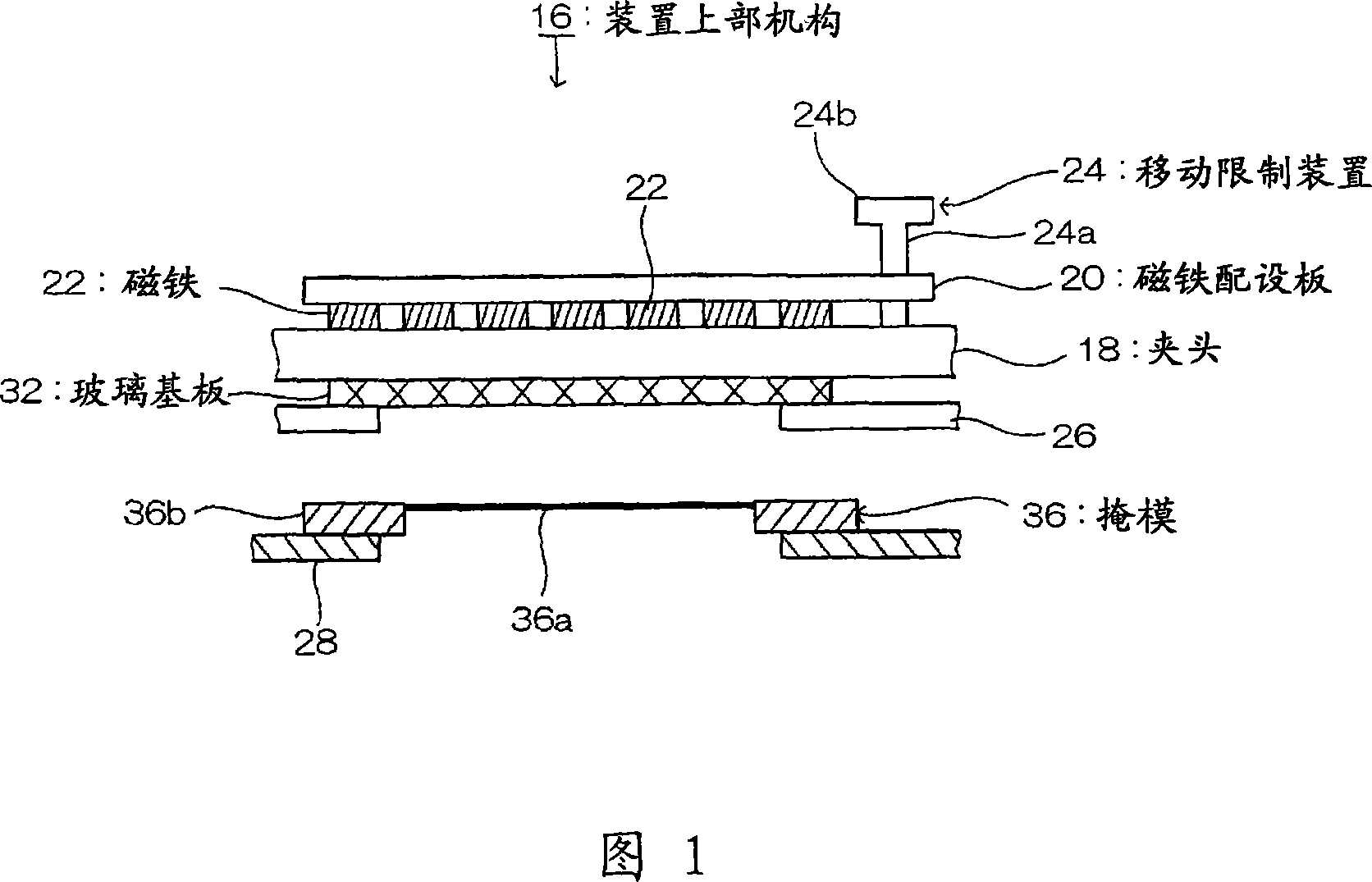

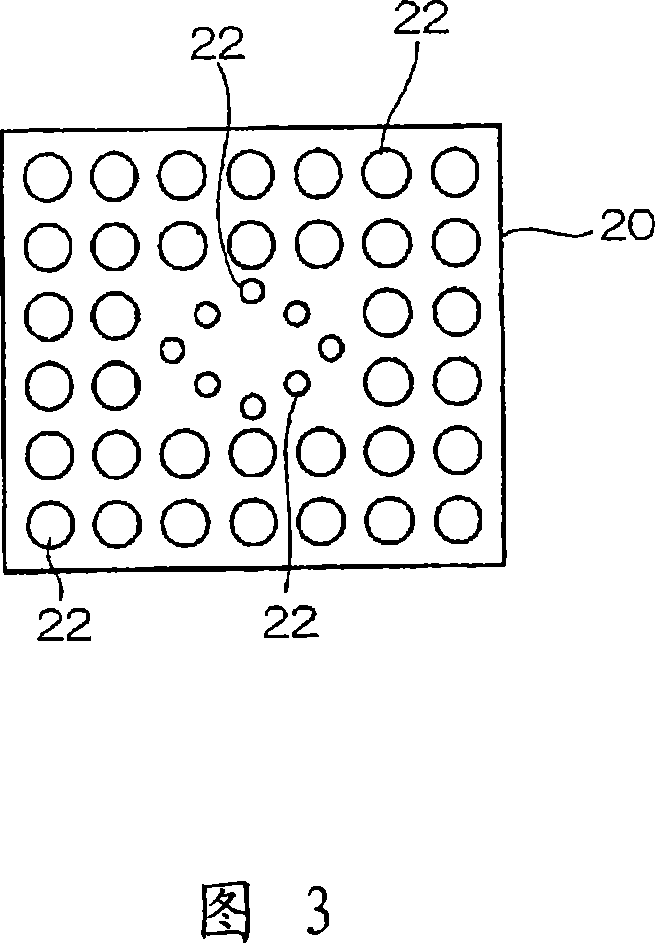

[0036] FIG. 1 is an explanatory diagram of an upper mechanism of a vacuum vapor deposition apparatus according to an embodiment. Fig. 2 is an explanatory diagram of a vacuum evaporation device. The vacuum evaporation apparatus 10 is provided at its bottom with an evaporation source 14 (supply source) of an organic material 12 and at its upper portion with an apparatus upper mechanism 16 . The apparatus upper mechanism 16 is a structure including a chuck 18 , a magnet arrangement plate 20 having a magnet 22 , a movement restricting device 24 , a substrate holder 26 , and a mask holder 28 .

[0037] The evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com