Coupling, wrapping agglomeration device for ultra fine particles in sound field of gaseous and solid jet flow

An ultra-fine particle and jet technology, which is used in the separation of dispersed particles, separation methods, auxiliary pretreatment, etc., can solve the problem of inability to form particle agglomeration of ultra-fine particles, and achieve the effect of wide operating area and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

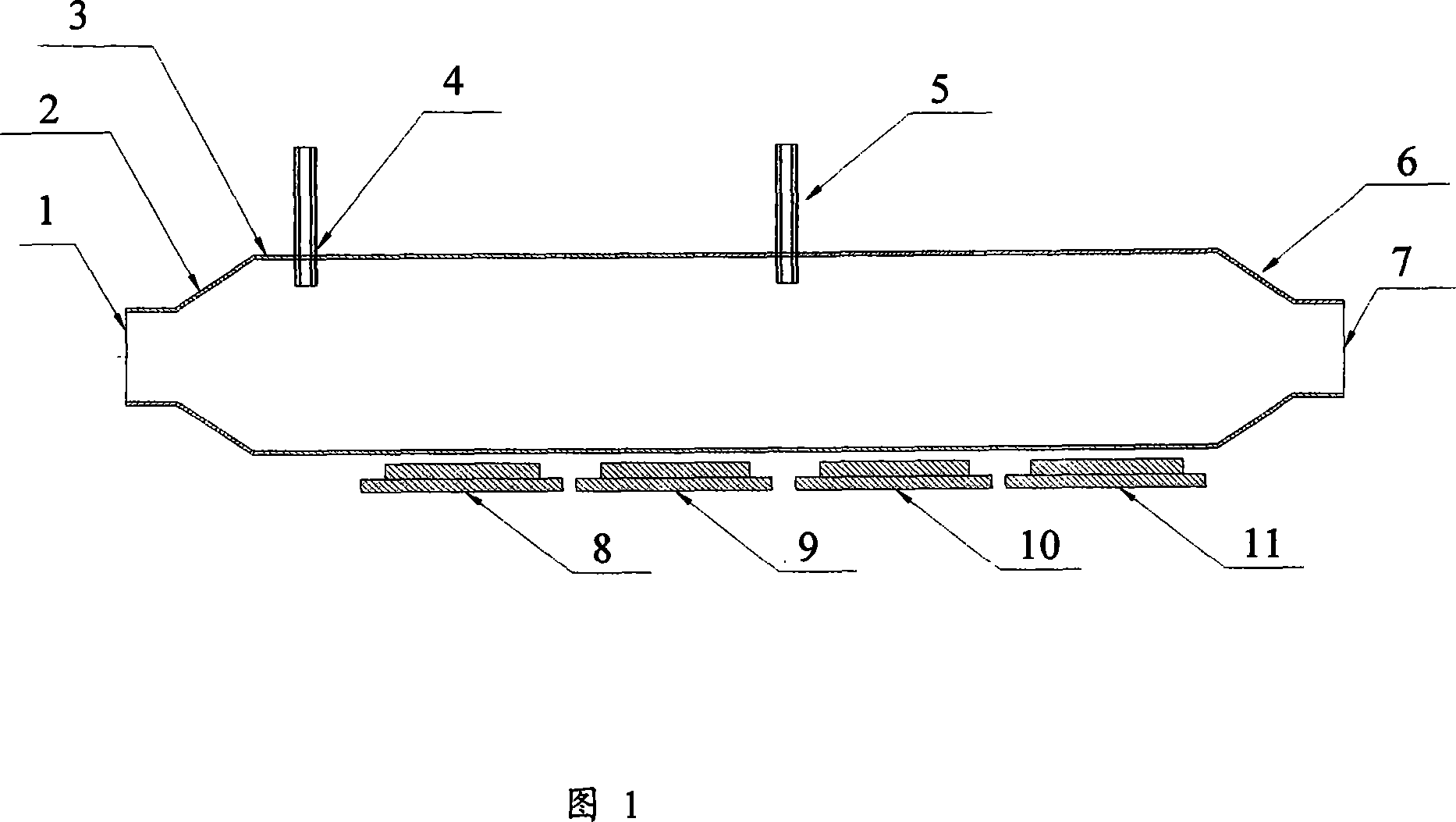

[0009] When the present invention is implemented, the main structure of the device includes a dust-laden gas inlet 1, an amplifying section 2, an ultrafine particle agglomeration chamber 3, a primary annulus jet tube 4, a secondary annulus jet tube 5, an agglomeration chamber shrinkage tube 6, and a shrinking section Outlet 7, primary loudspeaker 8, second-level loudspeaker 9, third-level loudspeaker 10, and fourth-level loudspeaker 11 are combined and assembled to form a long column structure. Disturbance of ultrafine particles; the primary annulus jet tube 4 is installed on the rear side of the amplification section 2, and it is fixed on the ultrafine particle agglomeration chamber 3 through a lock nut, and the two annulus jet tubes 4 and 5 are used for ultrafine particle agglomeration The length of the chamber 3 is adjusted by the lock nut; the primary speaker 8 is on the other side of the jet tube 4 in the primary annulus, and the included angle between the axis of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com