Automatic electrical control cabinet

A technology for electrical control cabinets and cabinet doors, which is applied in the direction of electrical components, electrical equipment casings/cabinets/drawers, electrical equipment structural parts, etc., can solve the problems of electrical control cabinet space limitations, low maintenance efficiency, etc., and improve maintenance Efficiency, improving work efficiency, and expanding the effect of the operating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

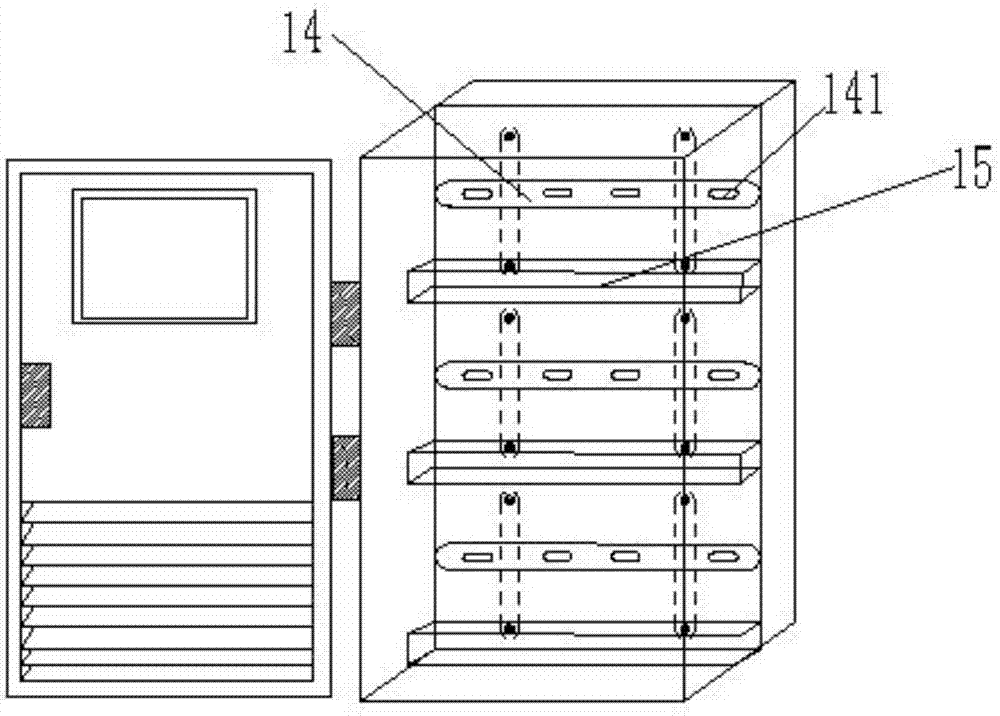

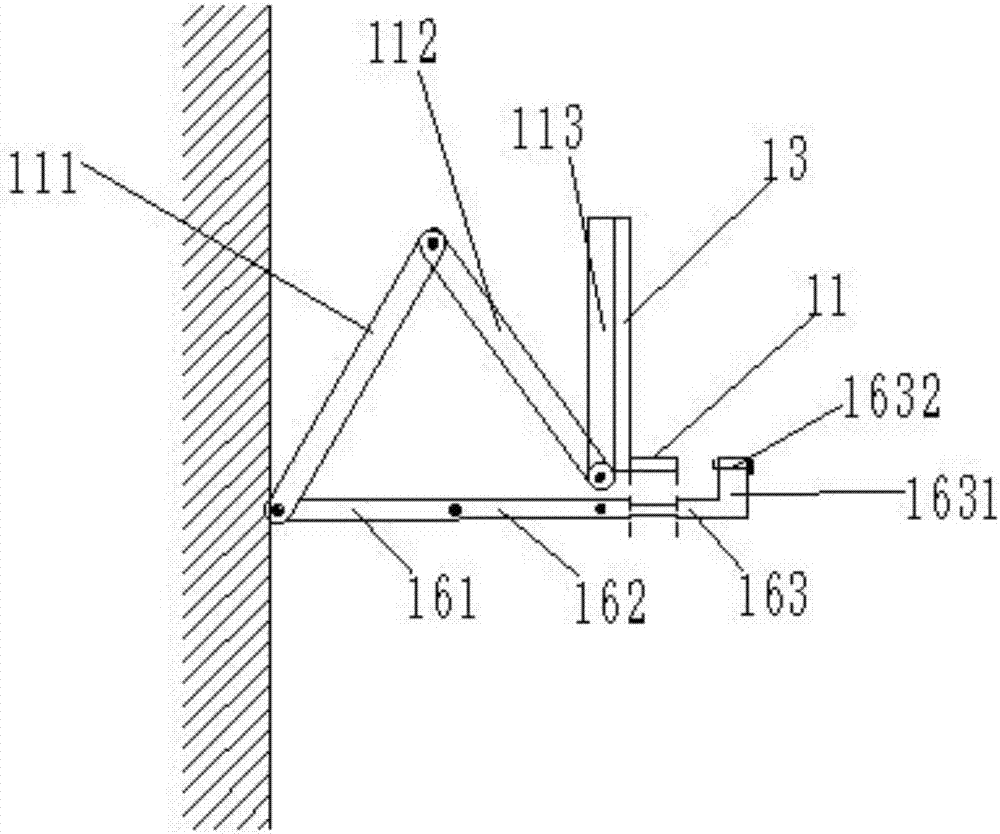

[0032] Embodiment 1: An automated electrical control cabinet, including a cabinet body and a cabinet door, the cabinet door is a side-opening cabinet door, the cabinet body includes a back wall and a side wall, the back wall and the side wall are integrally formed, and the control cabinet is also provided There is a movable back panel, which is parallel to the back wall and is movably set inside the cabinet. The height of the movable back panel is equal to the height of the back wall, and the width of the movable back panel is equal to the width of the back wall. The movable back panel includes multiple Installation area 1, multiple installation areas 1 are arranged in parallel, and the widths of multiple installation areas 1 are equal. The installation area 1 includes a movable bracket, a panel 13, a mounting bar 14 and a threading frame 15. One end of the movable bracket is fixedly arranged on the back wall, and the other end is connected to the panel 13, and the mounting bar ...

Embodiment 2

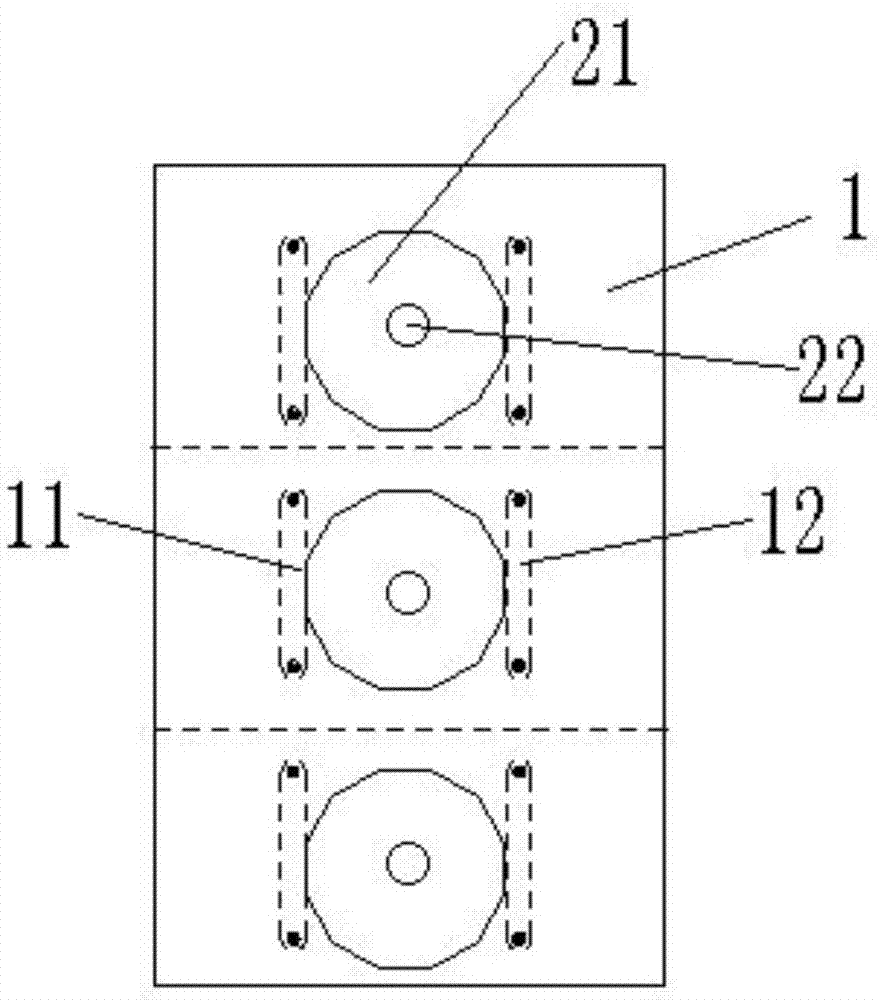

[0034] Embodiment 2: On the basis of embodiment 1, a safety protection device is provided between a plurality of the installation areas 1 and the back wall, the safety protection device is connected to the mobile back plate, and the safety protection device abuts against the back wall . The safety protection device includes an airbag 21, a piston 22, an inflation column 23 and a closed port 24. The piston 22 is sleeved in the inflation column 23 and is connected to the panel 13 at one end, and the other end is connected to the airbag 21 through the closed port 24. The airbag 21 is provided with a plurality of micropores, and the plurality of micropores are recessed inward. The airtight opening 24 is a conical opening, the small end of the conical opening is connected to the airbag 21, a small ball 241 is arranged in the airtight opening 24, and the small ball 241 is connected to the piston 22. The diameter of the small ball 241 is larger than the diameter of the small end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com