Strip mill of using combined type hydraulic cylinder of bending roller

A hydraulic cylinder and composite technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of difficult maintenance, many pipelines, many fault points, etc. The effect of small number of roads and convenient roll change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

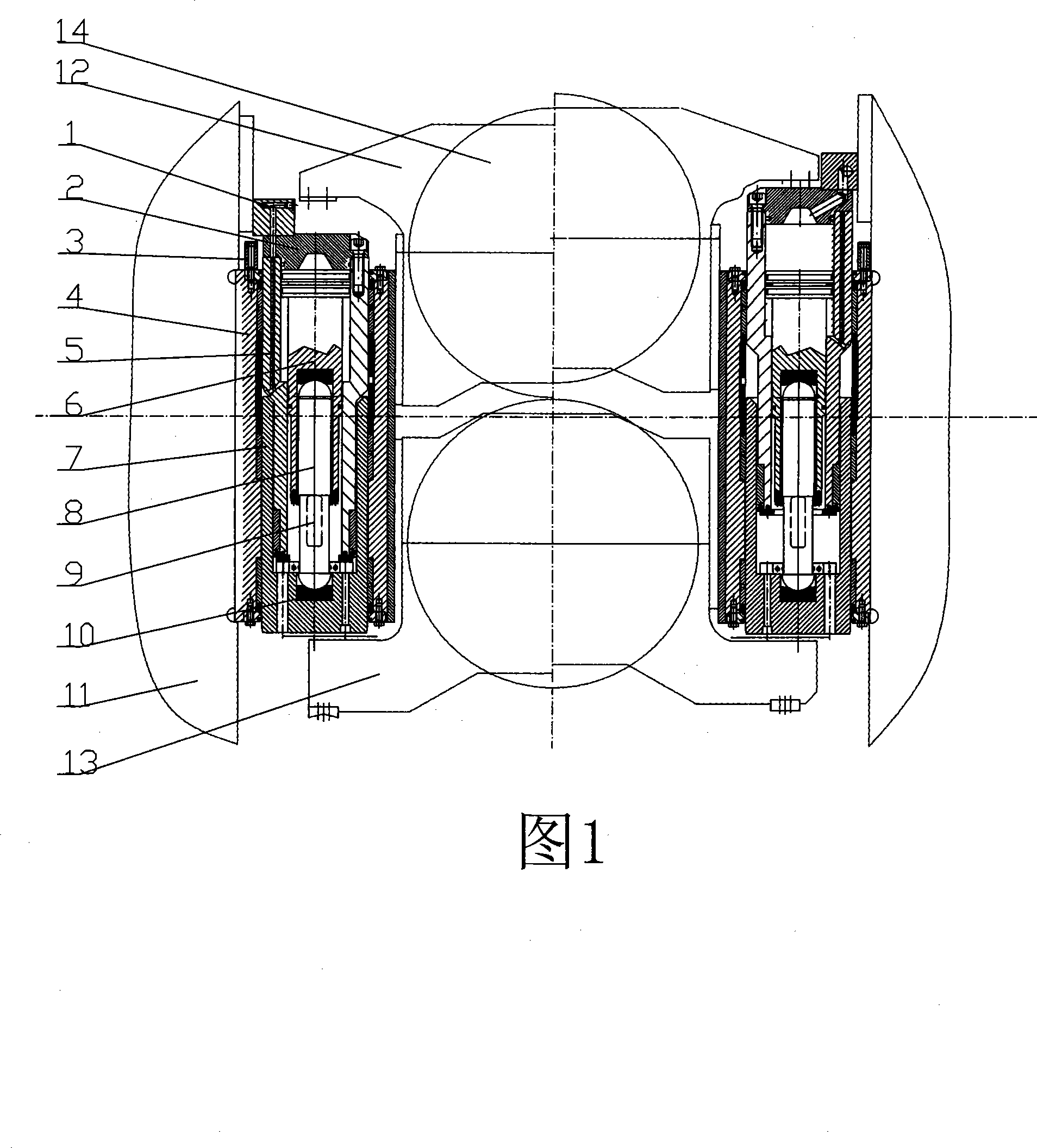

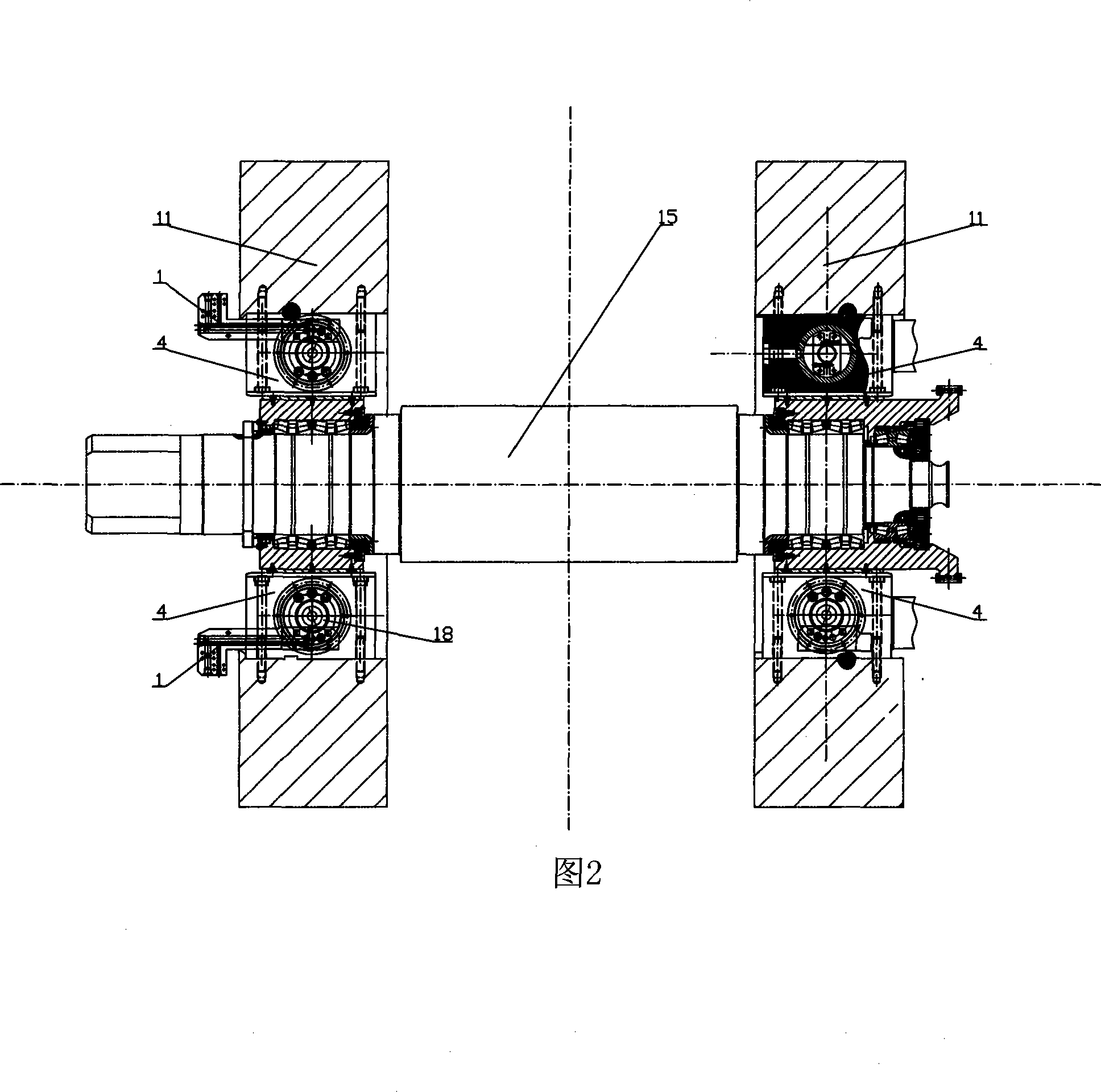

[0033] Concrete embodiment of the present invention is shown in accompanying drawing, adopts the strip mill of compound type bending roll hydraulic cylinder to only use four compound type bending roll hydraulic cylinders 18, is respectively installed on the upper, In the central circular hole of the fixed block 4 between the lower work roll chocks 12 and 13, it can float up and down and expand and contract. The four composite bending roll hydraulic cylinders have the same structure, see accompanying drawing 2 and accompanying drawing 8. Each compound bending hydraulic cylinder is mainly composed of oil inlet plate 1, upper platen 2, support plate 3, fixed block 4, cylinder body 5, piston rod 6, lower platen 7, connecting rod 8, guide key 9, spherical pad 10 And other parts, see accompanying drawing 1, accompanying drawing 7.

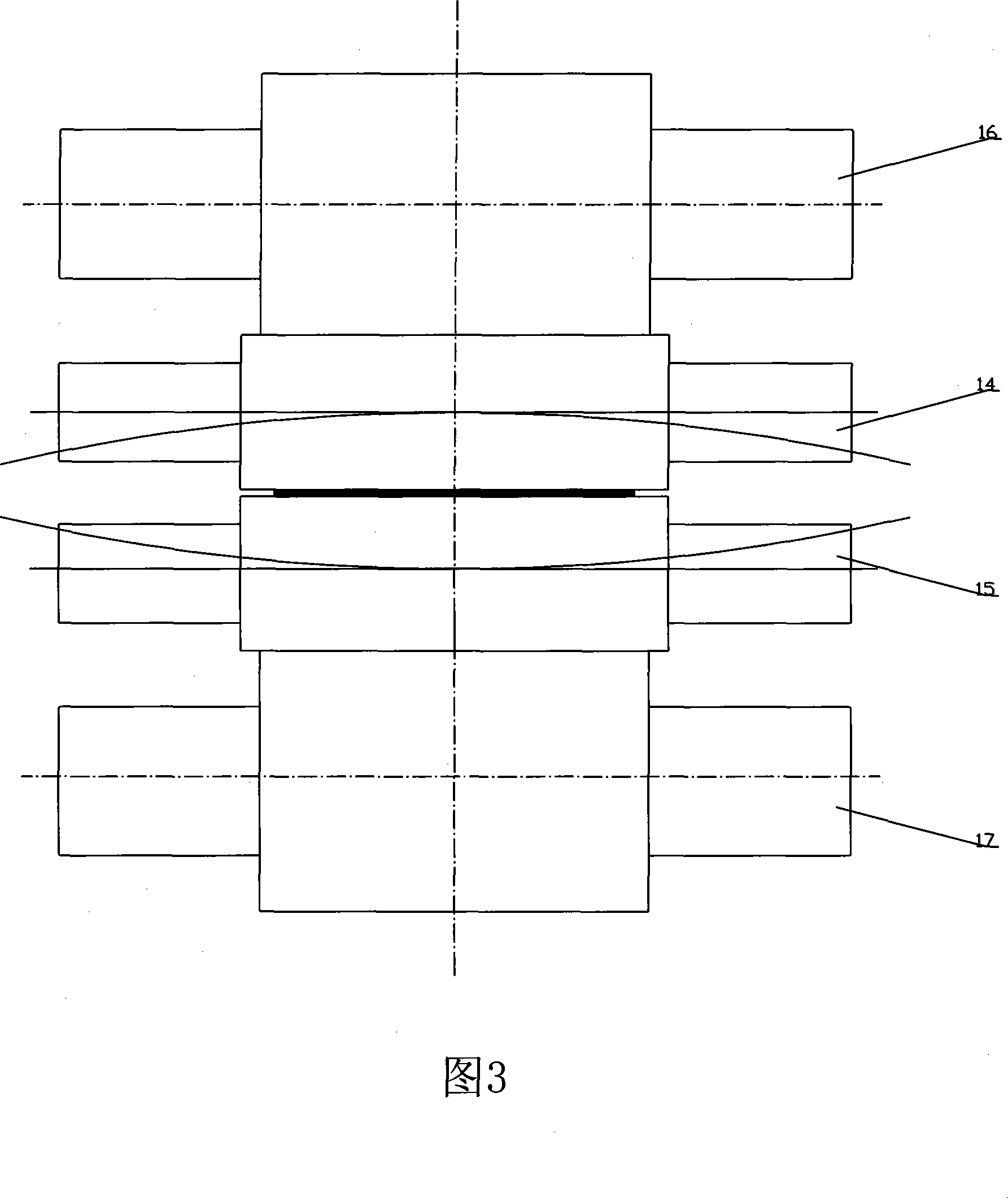

[0034] Whole rolling mill is that upper work roll 14 and lower work roll 15 are installed in the middle part of archway 11 by upper work roll chock 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com