Equipment capable of injection-molding product in large size with accuracy, injection-molding method, and product

A kind of injection molding product, large-scale technology, applied in other household appliances, household components, household appliances, etc., can solve the problems of one-time injection molding, etc., and achieve the effect of reliable quality, large storage capacity and high precision of injection molding products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

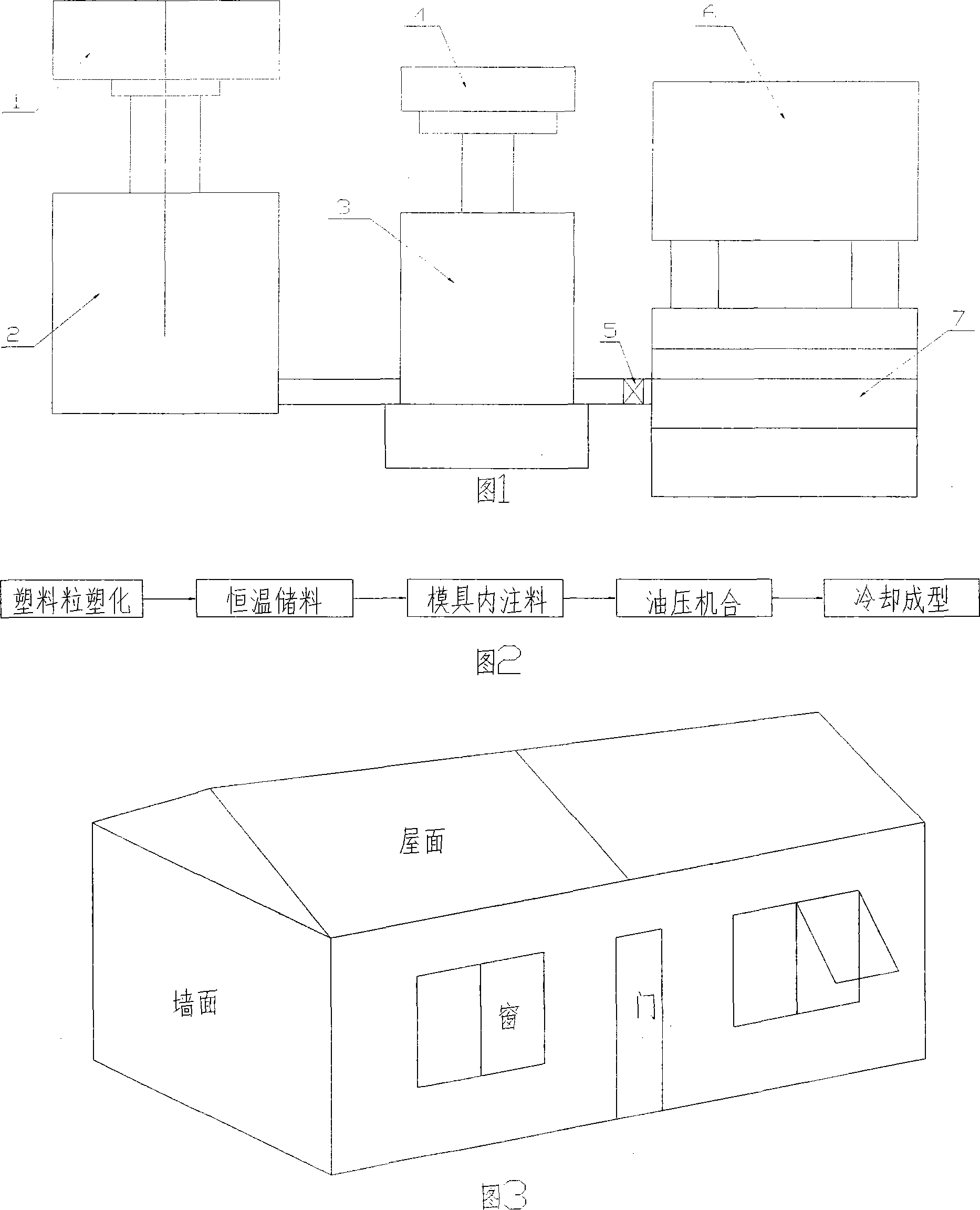

[0015] Embodiment 1: with reference to accompanying drawing 1. The equipment for precision injection molding of large-scale products, one or two or more large hydraulic presses is the existing equipment, and its workbench is used to control the clamping and opening of the hot runner injection mold. The processing and production of the hot runner injection mold are modern There are technologies, which will not be described here. One or two or more injection molding units are fixed or mobile. The discharge port of one or two or more storage constant temperature injection molding cylinders is connected with the feed inlet of the hot runner injection mold. The storage constant temperature injection molding cylinder is composed of cylinder body, piston, material inlet, discharge port and check valve. Composition, the cylinder body is a thermal insulation cylinder body, the piston is an oil cylinder piston and is controlled by the oil cylinder and an automatic control device, and t...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, a plastic injection constant pressure device can be installed on the hot runner injection mold system.

Embodiment 3

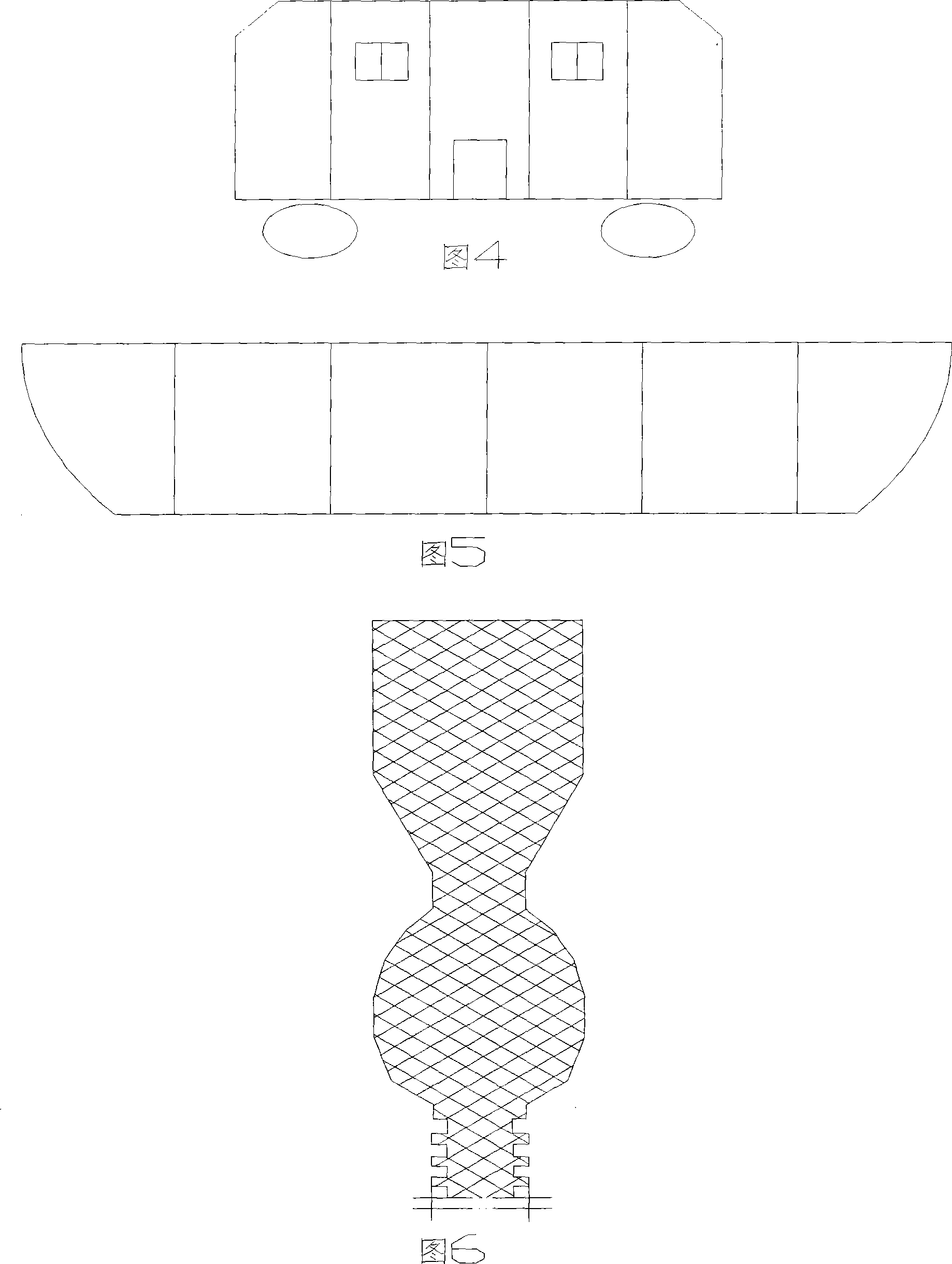

[0018] Example 3: On the basis of Example 1, the large injection molded product in the hot runner injection mold uses a compressed gas top plate or multiple cylinder piston top plates to push the large injection molded product out of the mold; or uses an air pump to lift the injection molded product. Out of the mold ----- the mold with dense small cavities as reinforcing ribs can be made into the shape of the valve core cover of the automobile engine, and the steam pressure is blown from the side of the rod core to lift the core cover from the gap of the cover. And make more gas enter the mold cavity and hold up the product. It is convenient for the product to be released from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com