A Well Killing Method After Gas Drilling Blowout

A gas drilling and well killing technology, which is applied to drilling with liquid/gas jet, wellbore/well components, earth-moving drilling and production, etc., can solve the problems of difficulty in establishing a well-killing liquid column, and achieves easy well-killing steps, easy application of The effect of wellhead back pressure and low operating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

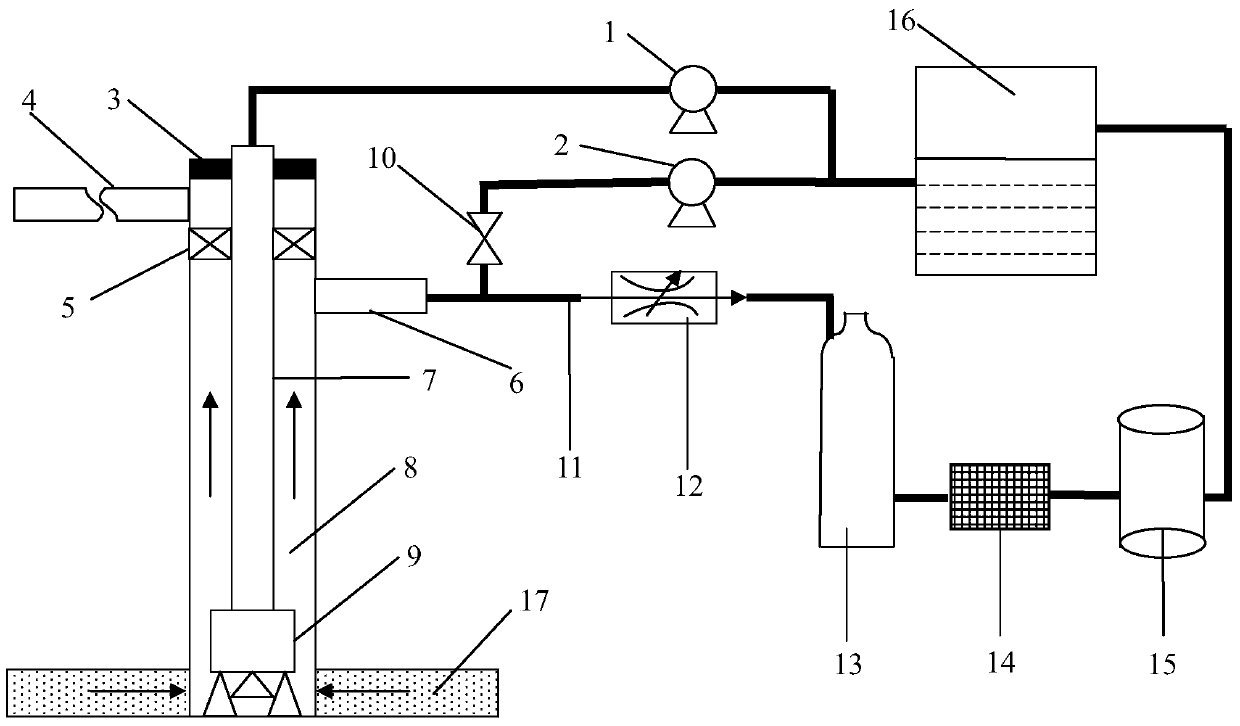

[0029] Attached below figure 1 First, the connection structure of components and devices involved in the present invention will be described.

[0030] After drilling into the gas layer, the air compressor and other equipment used for gas drilling shall be dismantled first, and a figure 1 connection shown. The first circulation process is: connect the conventional drilling pump 1 to the mud pool 16 and the wellhead drilling tool 7, and the drilling pump 1 pumps the drilling fluid in the mud pool 16 into the drilling tool 7, and then carries the formation gas into the ring after passing through the bottom hole drill bit 9. Empty 8, because the wellhead blowout preventer group 5 is closed, the gas-liquid two-phase flow in the annular space 8 enters the throttling manifold 11 through the four-way 6, and the gas-liquid two-phase flow enters the gas-liquid separation after being throttled by the throttle valve 12 After that, the drilling fluid enters the mud pool 16 after being tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com