Intellective control system with multiple CPUs for motorcycle and control method

An intelligent control system and motorcycle technology, applied in the field of motorcycles, can solve problems such as fuel waste, easy engine flameout, and motorcycles prone to rushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

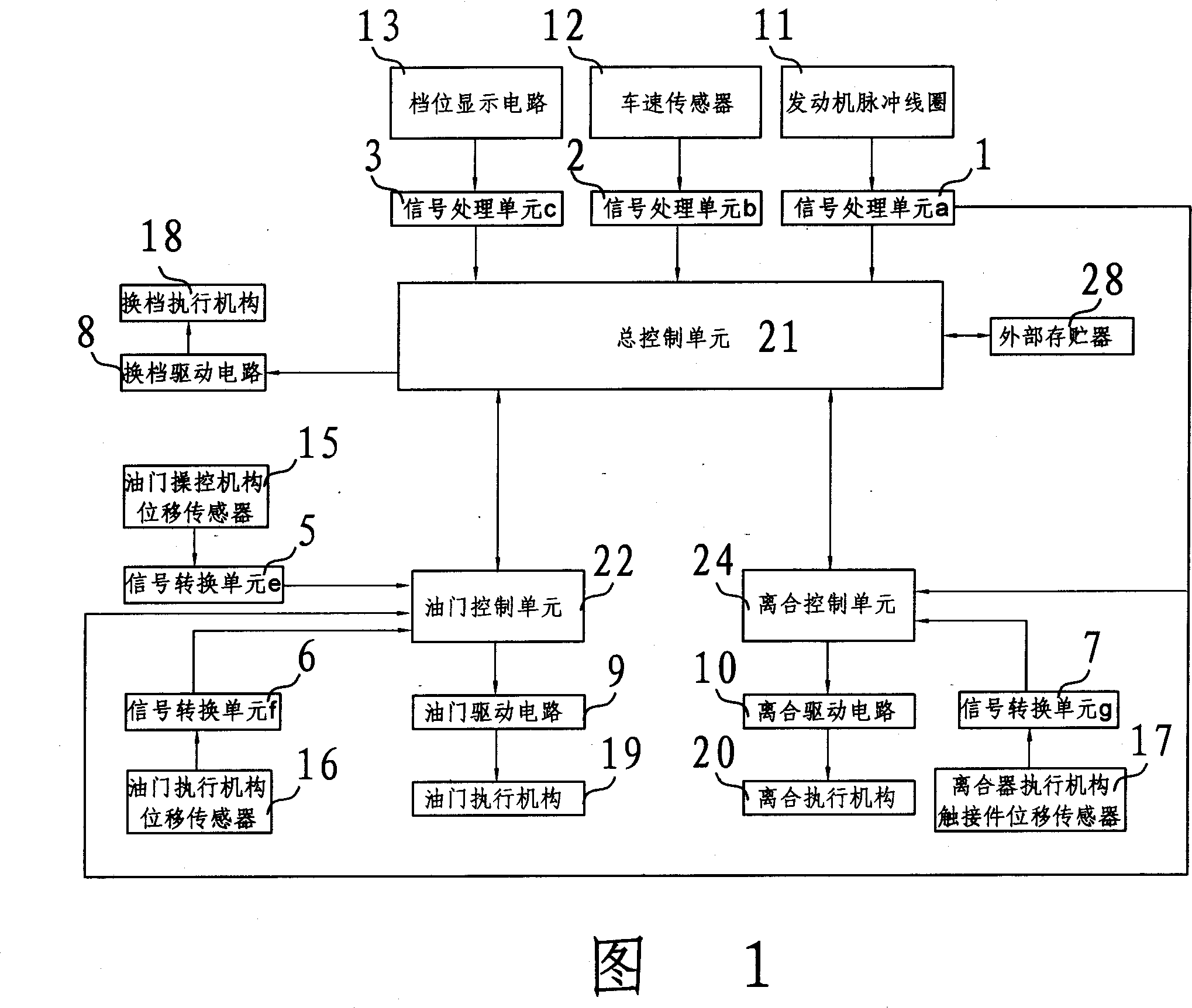

Embodiment 1

[0155] As shown in Figure 1: the motorcycle multi-CPU intelligent control system is mainly composed of a total control unit 21, an accelerator control unit 22 and a clutch control unit 24, the total control unit 21 is connected with the gear display circuit 13 through a signal processing unit c3, and is To collect the gear position information of the engine; the total control unit 21 is connected with the vehicle speed sensor 12 through the signal processing unit b2, and the outer end of the output shaft of the gear box on the engine body 110 is fixed with a vehicle speed detection gear 105 through a spline, and the corresponding vehicle speed sensor on the engine body 110 The position of vehicle speed detection gear 105 gear teeth is provided with vehicle speed sensor 12, and this vehicle speed sensor 12 is proximity switch, is used to detect the running speed of motorcycle; General control unit 21 is connected with engine pulse coil 11 by signal processing unit a1, is used for...

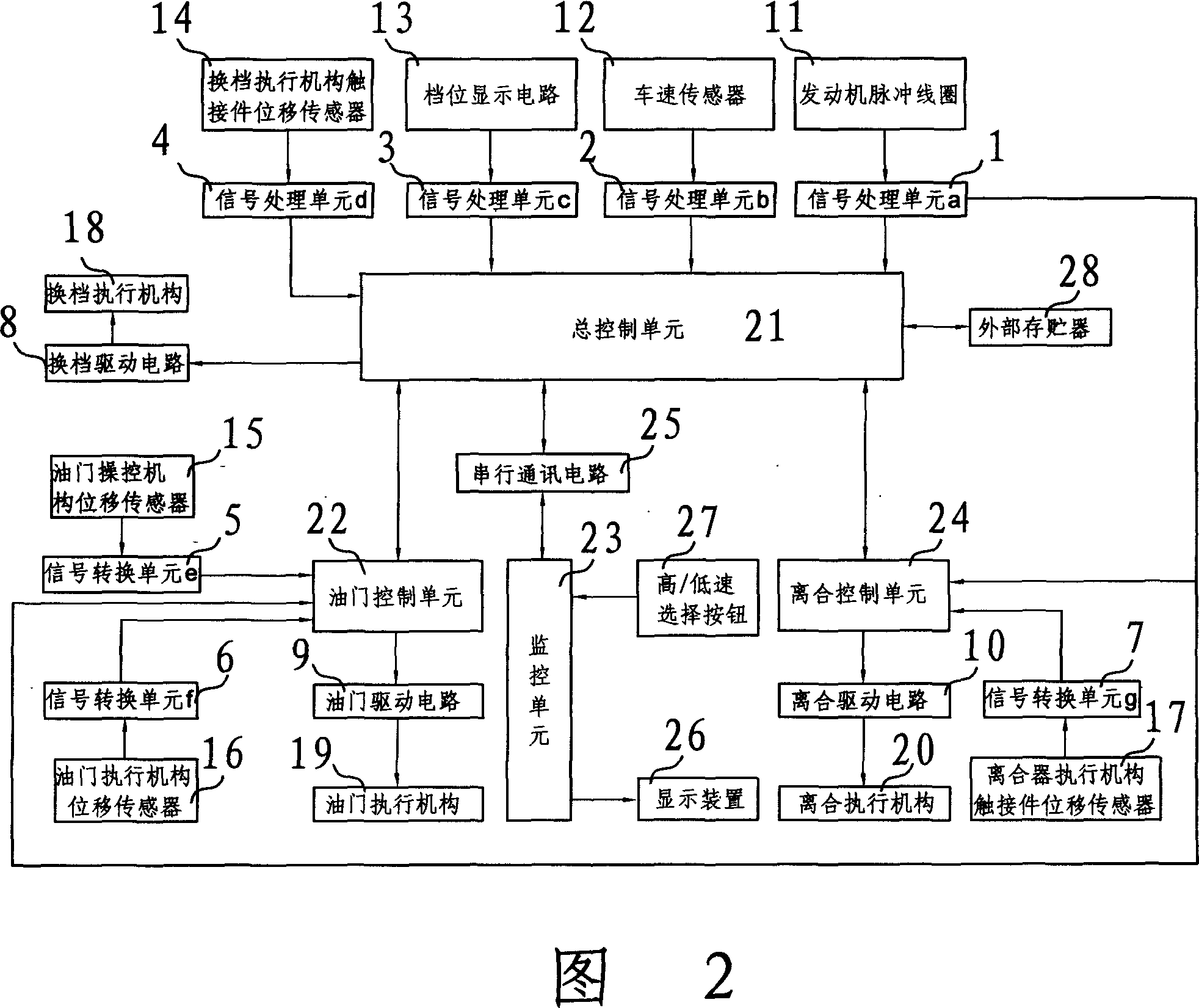

Embodiment 2

[0216] As shown in Fig. 2 and Fig. 5: the motorcycle multi-CPU intelligent control system is mainly composed of a general control unit 21, an accelerator control unit 22 and a clutch control unit 24. The connector displacement sensor 14 is connected to collect the displacement information of the contact member of the gearshift mechanism. The total control unit 21 is connected to the gear display circuit 13 through the signal processing unit c3 to collect the gear information of the engine; the total control unit 21 The signal processing unit b2 is connected to the vehicle speed sensor 12, and the outer end of the output shaft of the gear box on the engine body 110 is fixed with a vehicle speed detection gear 105 through a spline, and a vehicle speed sensor is provided at the position corresponding to the vehicle speed detection gear 105 teeth on the engine body 110 12. The vehicle speed sensor 12 is a proximity switch for detecting the running speed of the motorcycle; the overa...

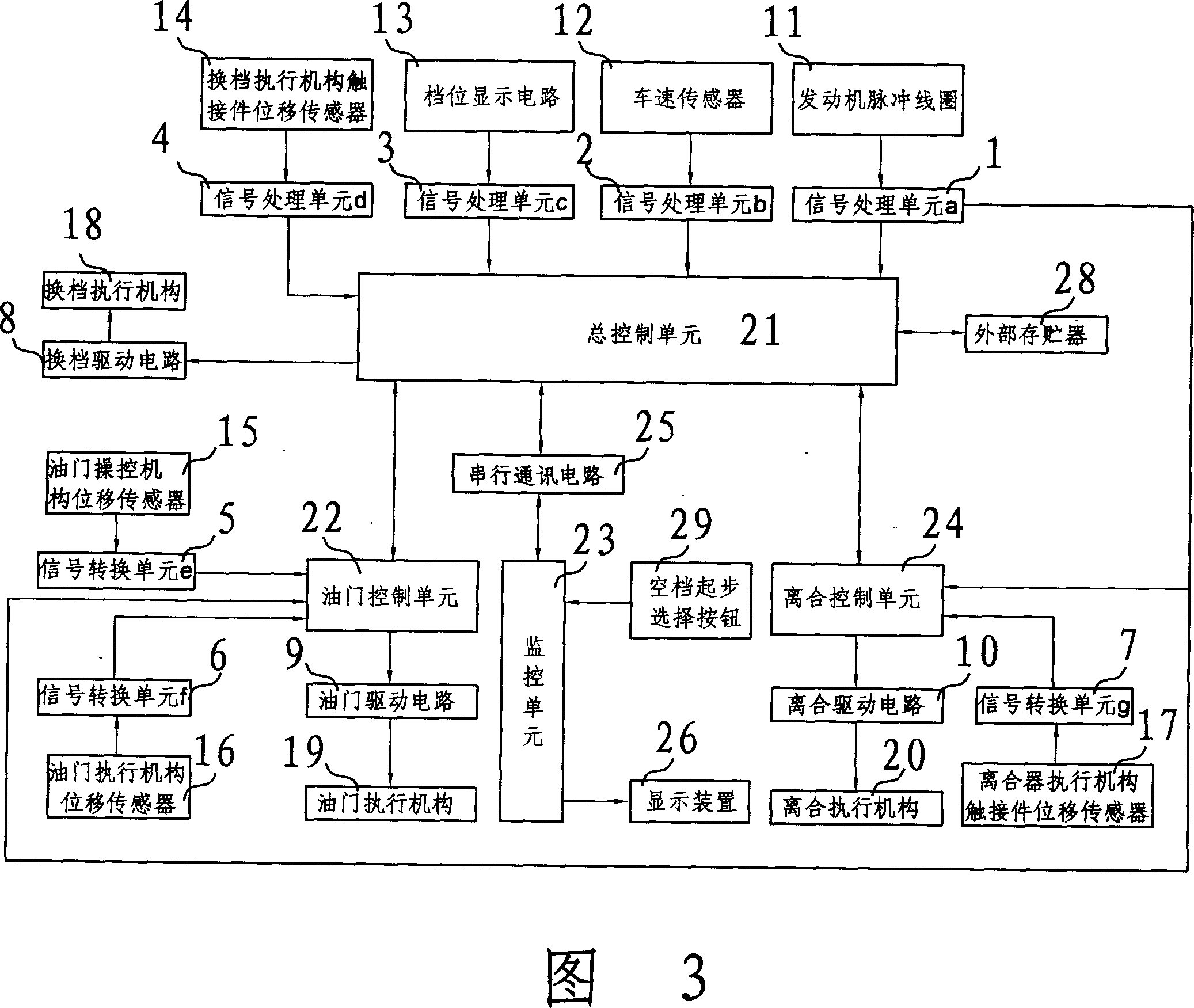

Embodiment 3

[0232]As shown in Fig. 3 and Fig. 5: the motorcycle multi-CPU intelligent control system is mainly composed of a total control unit 21, an accelerator control unit 22 and a clutch control unit 24. The contact displacement sensor 14 is connected to collect the displacement information of the contact of the gearshift mechanism. The total control unit 21 is connected to the gear display circuit 13 through the signal processing unit c3 to collect the gear information of the engine; the total control unit 21 is connected with the vehicle speed sensor 12 through the signal processing unit b2. The outer end of the output shaft of the gear box on the engine body 110 is fixed with a vehicle speed detection gear 105 through a spline. Sensor 12, the vehicle speed sensor 12 is a proximity switch, used to detect the running speed of the motorcycle; the total control unit 21 is connected with the engine pulse coil 11 through the signal processing unit a1, and is used to collect the rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com