Method for realizing microgrid control system based on high-speed Ethernet industrial bus

An industrial bus and control system technology, applied in the field of micro-grid system, to achieve the effect of easy engineering implementation, conducive to expanding application, and improving data transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

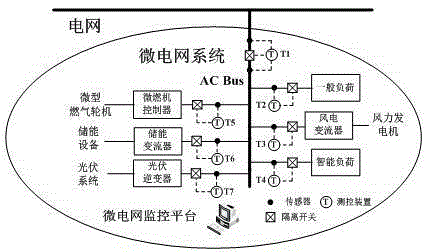

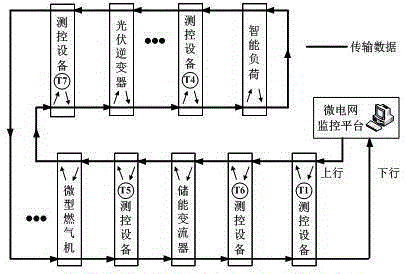

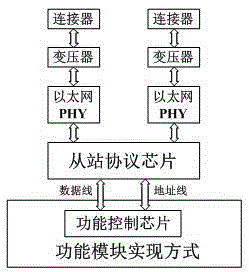

[0027] An implementation method of a micro-grid control system based on a high-speed Ethernet industrial bus of the present invention is suitable for a typical micro-grid system composed of distributed power sources, measurement and control equipment, loads, and micro-grid monitoring systems, among which distributed power sources, measurement and control equipment, etc. Information exchange is realized through the EtherCAT industrial bus, and the status of the grid-connected point voltage, current, and isolating switch of the micro-grid system can be transmitted to the distributed power supply and other equipment more quickly according to a specific connection sequence, so as to realize the multi-objective and stable operation of the micro-grid system.

[0028] A method for implementing a micro-grid control system based on a high-speed Ethernet industrial bus in the present invention will figure 1 The distributed power supply, measurement and control equipment, load and microg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com