Recuperator tube device used for boiler

A technology for heat exchange tubes and boilers, which is applied in the direction of boiler water tubes, etc., and can solve the problems of easy falling off of the refractory material layer and different thermal expansion coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

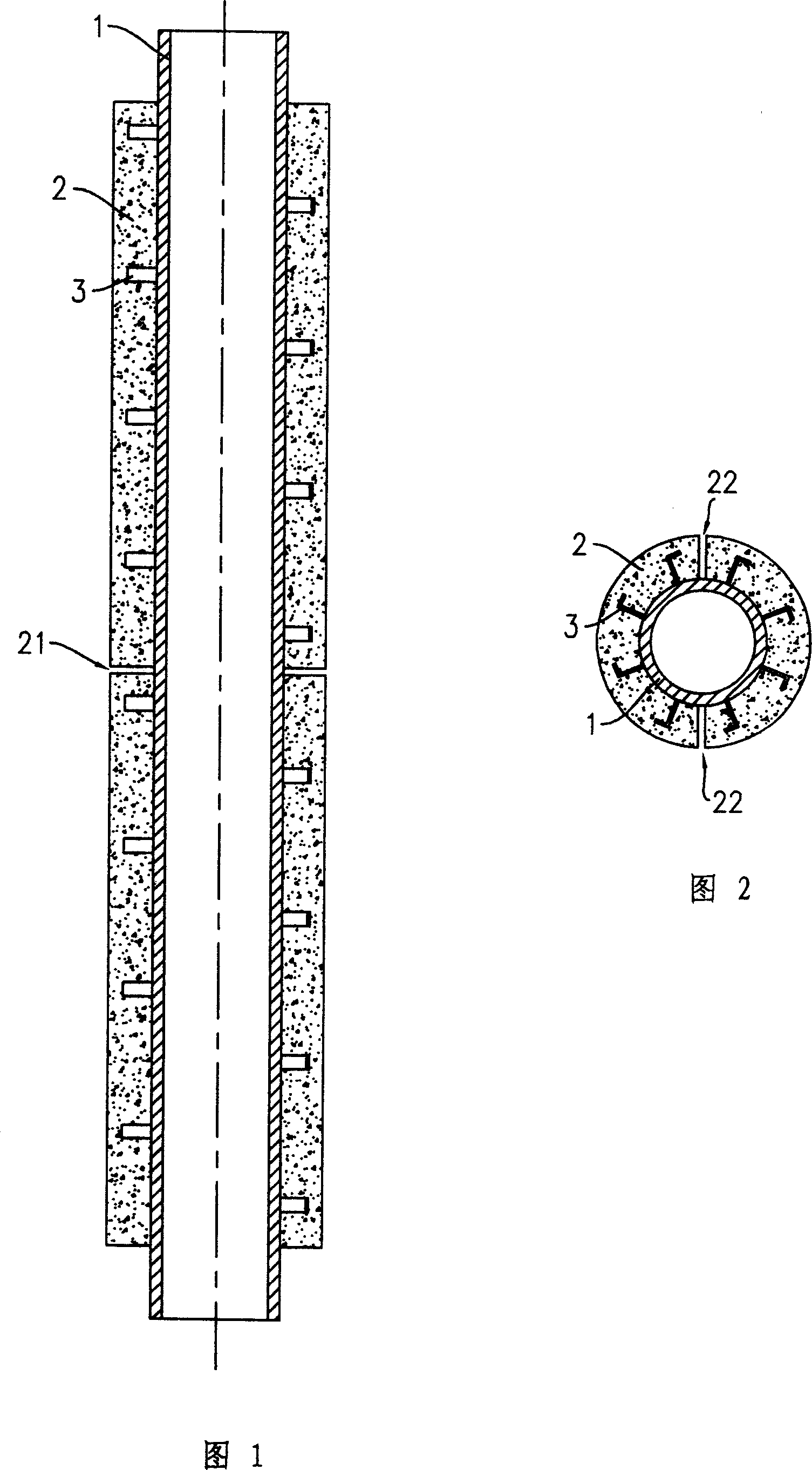

[0012] The heat exchange tube device for a boiler, as shown in Figure 1 and Figure 2, includes a heat exchange tube body 1, and a refractory material layer 2 coated on the heat exchange tube body 1, and the heat exchange tube body 1 is made of metal material, and the refractory material layer 2 is made of refractory material. The root of the fixing claw 3 is fixed on the outer surface of the heat exchange tube body 1. After the refractory material is cast on the outer peripheral surface of the heat exchange tube body 1, the fixing claw 3 can make the refractory material layer 2 firmly adhere to the heat exchange tube ontology. According to needs, many fixing claws 3 can be provided, and these fixing claws 3 are arrayed in the circumferential direction of the heat exchange tube body 1, and the fixing claws 3 between two adjacent ring array groups are arranged in a staggered manner, so that the distribution is more precise. Uniform, better grip. For the sake of simplicity, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com