Vertical and horizontal processing center main-shaft box system

A machining center and spindle box technology, applied in metal processing equipment and other directions, can solve the problem of high price, reduce production costs and simplify the transmission structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

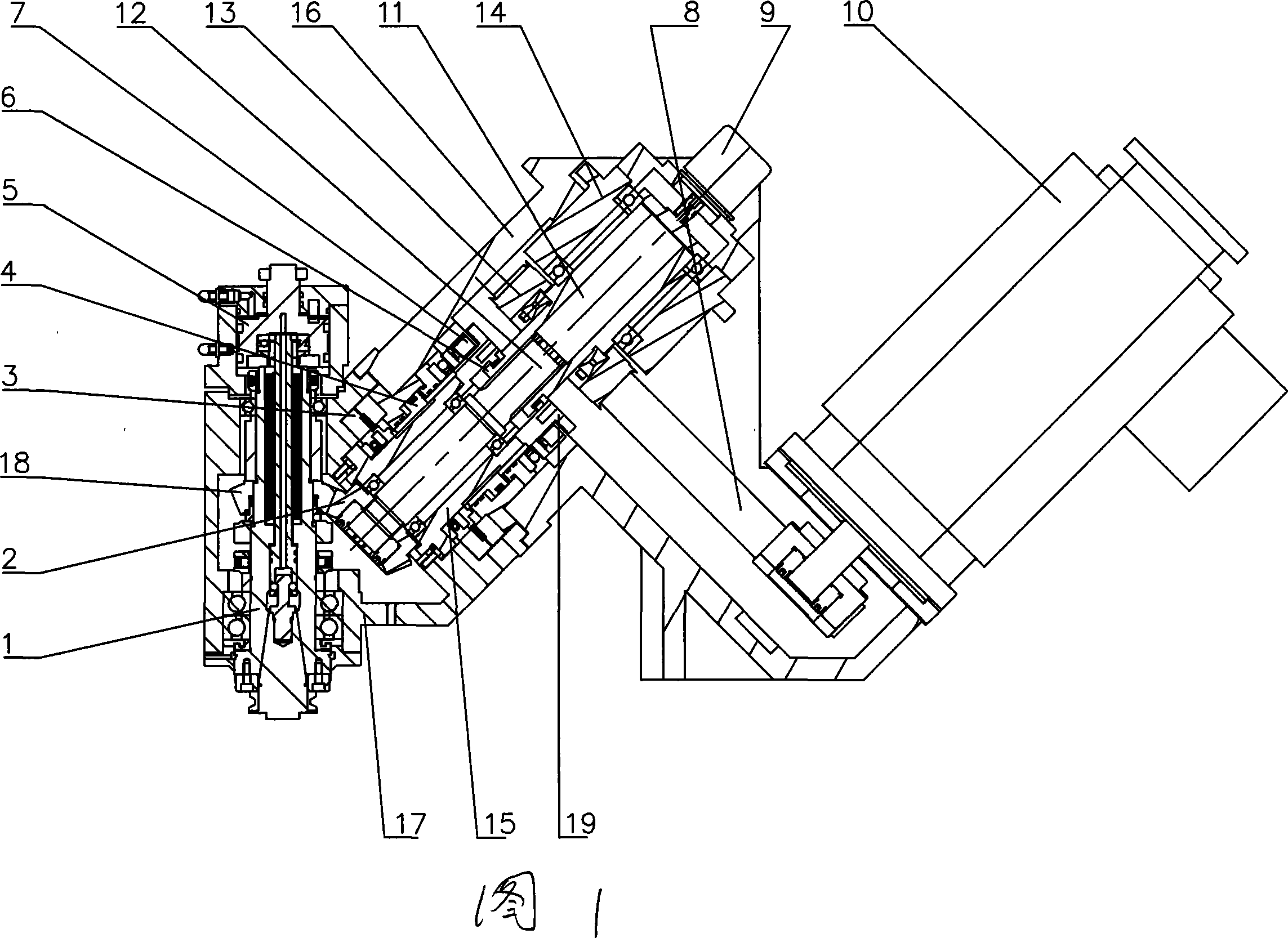

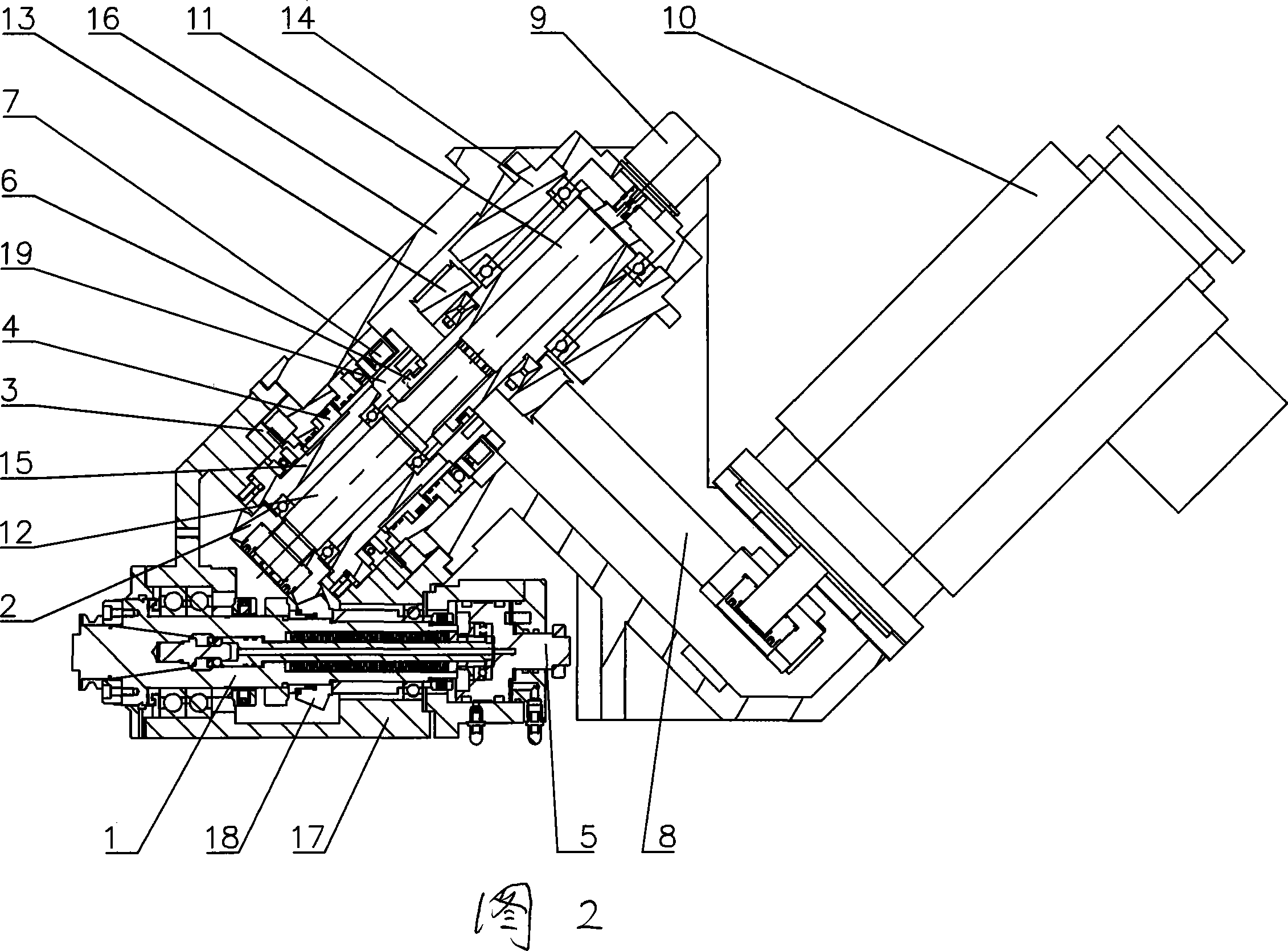

[0016] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Fig. 1, Fig. 2, the present invention comprises main motor 10, transmission assembly and spindle head; Above, the output of the main motor 10 drives the main transmission shaft 11 in the transmission assembly through the synchronous belt 8; A spiral bevel gear 18 is sheathed on the main shaft 1 in the main shaft 1, and the spiral bevel gear 18 on the main shaft 1 meshes with the spiral bevel gear 2 fixed at one end of the transmission shaft in the transmission assembly.

[0017] The two ends of the transmission shaft are placed in the upper bearing seat 14 and the shaft sleeve 15 in the main shaft box body 16. The transmission shaft is composed of the main transmission shaft and the driven transmission shaft 12 connected by splines. The main motor 10 is passed through the timing belt 8 The transmission is fixed on the synchronous pulley 13 on the main transmissi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap