Plastic mould rapid heating and cooling temperature controlling device

A technology of temperature control device and plastic mold, which is applied in the direction of temperature control by electric means, can solve the problems of long heating and cooling time, low temperature control accuracy, and narrow temperature range, and achieve low production cost and temperature control range The effect of wide, high peak temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

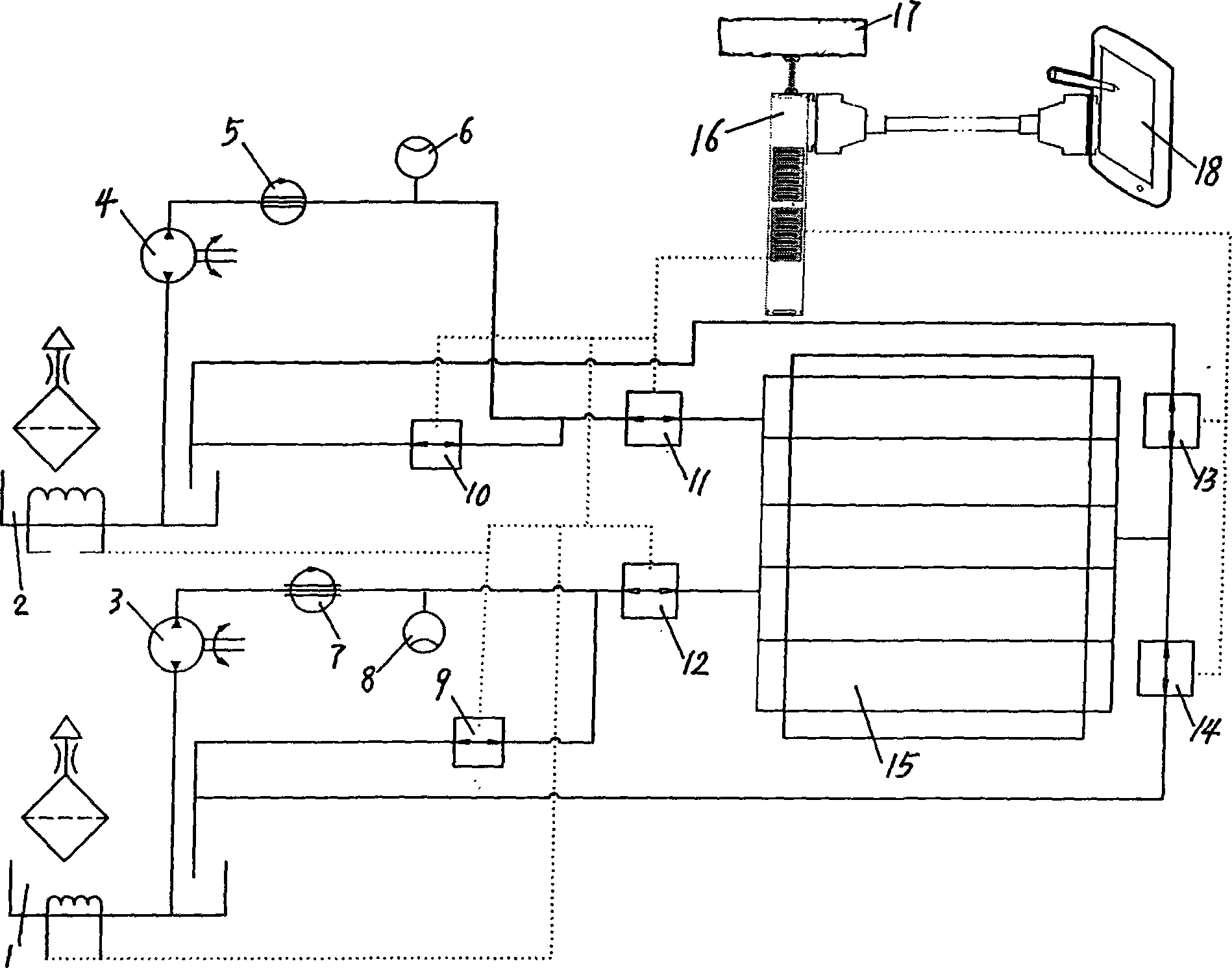

[0015] Accompanying drawing has provided the structural principle schematic diagram of the present invention. The temperature control device for rapid heating and cooling of plastic molds of the present invention mainly includes a heating device 1, a cooling device 2, a high-temperature power device 3, a low-temperature power device 4, pressure gauges 6 and 8, flow regulating valves 5 and 7, and a pneumatic electromagnetic angle seat Valves 9-14, programmable logic controller (PLC) 16, power supply 17, touch screen 18. The heating device 1 is connected with the high temperature power device 3 , and the cooling device 2 is connected with the low temperature power device 4 . The heating device 1, the high-temperature power device 3 and the plastic mold 15 form a circulation loop through pipelines, and the pipelines are filled with heat medium. In the circulation loop, the pipeline where the medium enters the plastic mold is equipped with a flow regulating valve 7, a pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com