Automatic ink-saving device for ink barrel

An ink barrel and automatic technology, which is applied in the field of supporting equipment for ink cartridges used in printers, can solve the problems of ink that cannot be recycled, cannot be sucked, and wasted, and achieves the effects of saving ink, being convenient to move, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

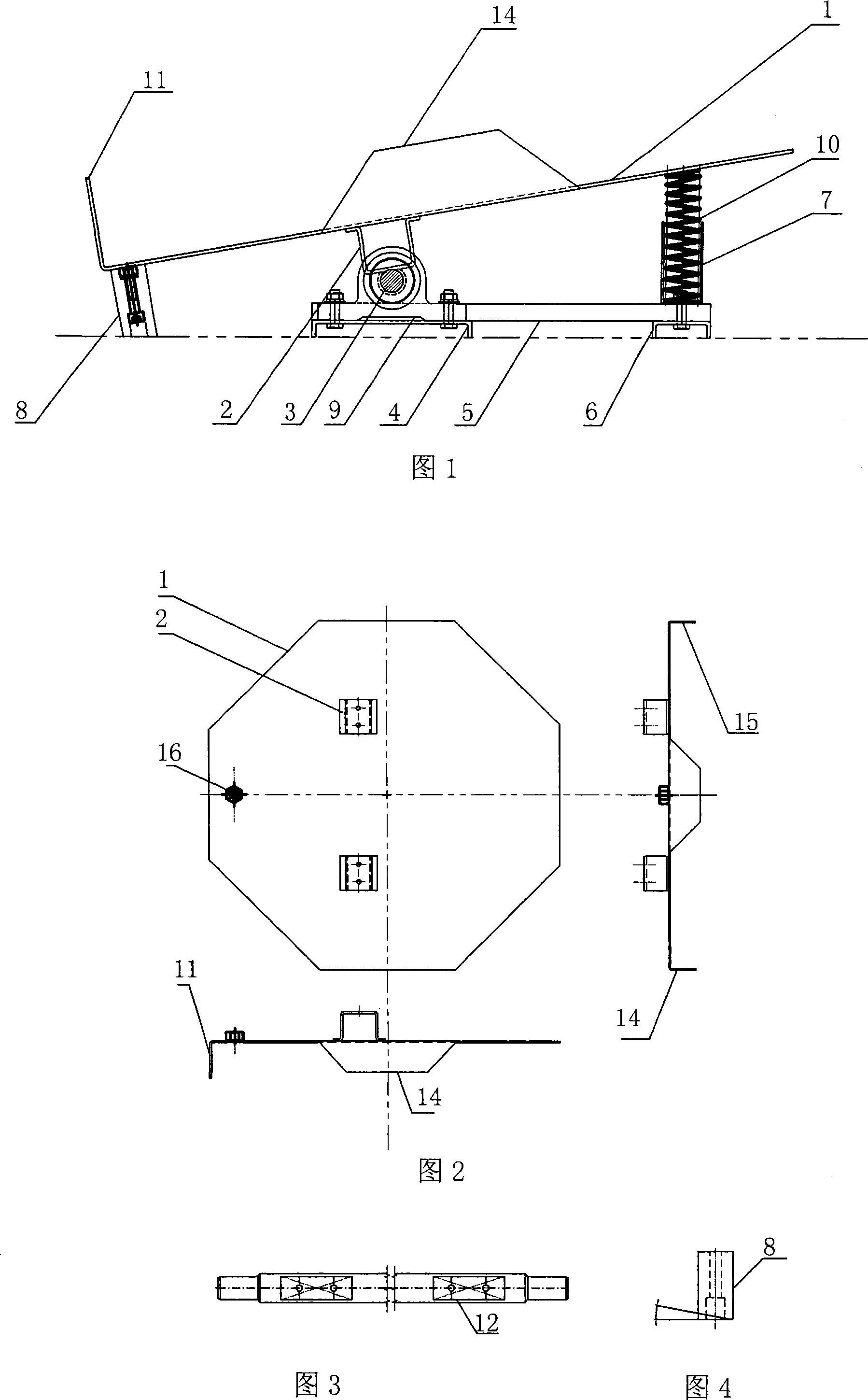

[0010] As shown in Figures 1, 2, 3, and 4, an automatic ink-saving device for ink barrels, the connecting plate 5, the spring bracket 6, and the load-bearing bracket 4 are U-shaped plates, and the two ends of the connecting bracket 5 are connected to the spring bracket 6 and the load-bearing bracket respectively. The bracket 4 is fixedly connected by screws to form an I-shape, the two ends of the supporting plate shaft 3 are respectively inserted into the bearings of the bearing housing 9 with bearings, and the bearing housing 9 is respectively fixed on the two ends of the load-bearing bracket 4 with screws, and the spring sleeve 7 is Stainless steel pen barrel shape, with a screw hole at the center line of the seal, the two spring sleeves 7 are respectively fixed on the two ends of the spring support 6 with screws, and the two springs 10 are respectively placed in the two spring sleeves 7, and the springs 10 Part stretches out of the spring barrel 7, and the ink bucket support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com