Movable vacuum apparatus

A vacuum device and hollow technology, which is applied in the field of side wall vacuum seals and movable vacuum devices, can solve the problems of sealing ring wear, inconvenient chamber frequent opening and closing, tearing, etc., and achieve low manufacturing cost, reduced processing accuracy and mutual With the effect of precision and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

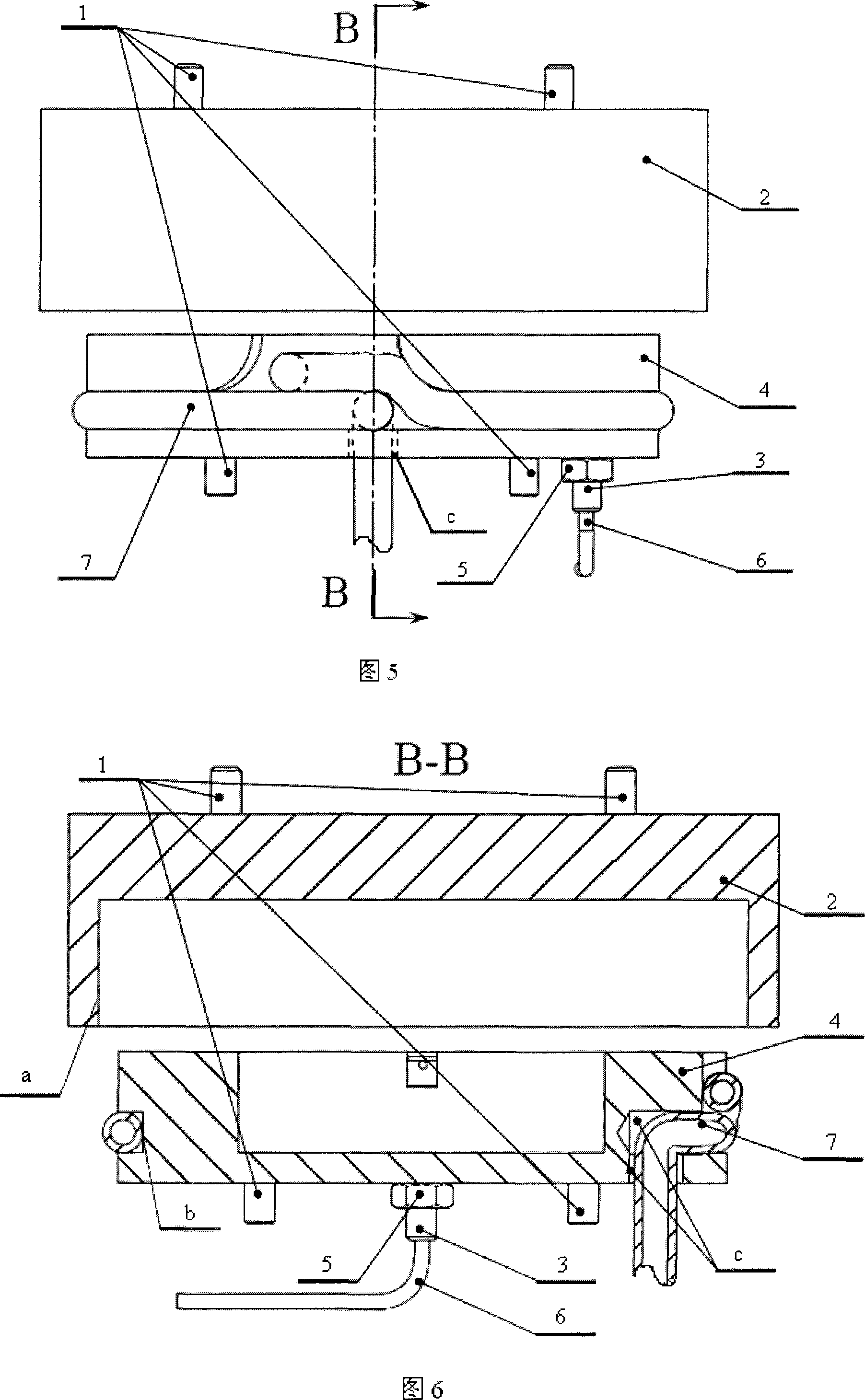

[0016] The specific implementation manner of an embodiment will be described in detail below in conjunction with the accompanying drawings.

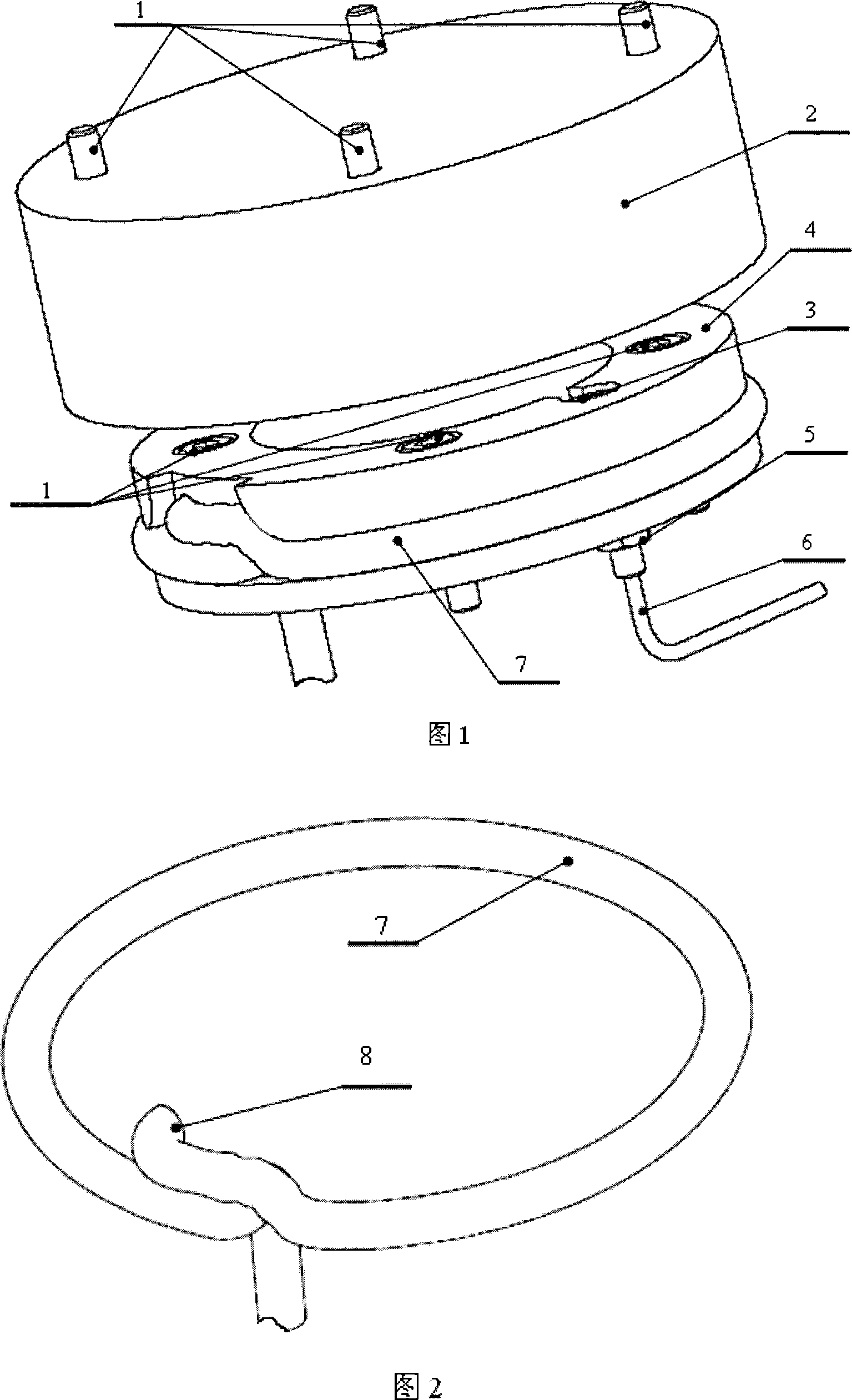

[0017] As shown in Figure 1, a movable vacuum device uses a gas-liquid hose 7 as its sealing ring to replace the O-ring usually used as a movable side wall seal. By filling the gas-liquid hose 7 with pressurized gas or The liquid expands the hose to achieve chamber sealing, and at the same time, the gas-liquid hose 7 can be used to shrink after the gas or liquid is drawn out, so that the two chambers can be separated and joined frequently and quickly.

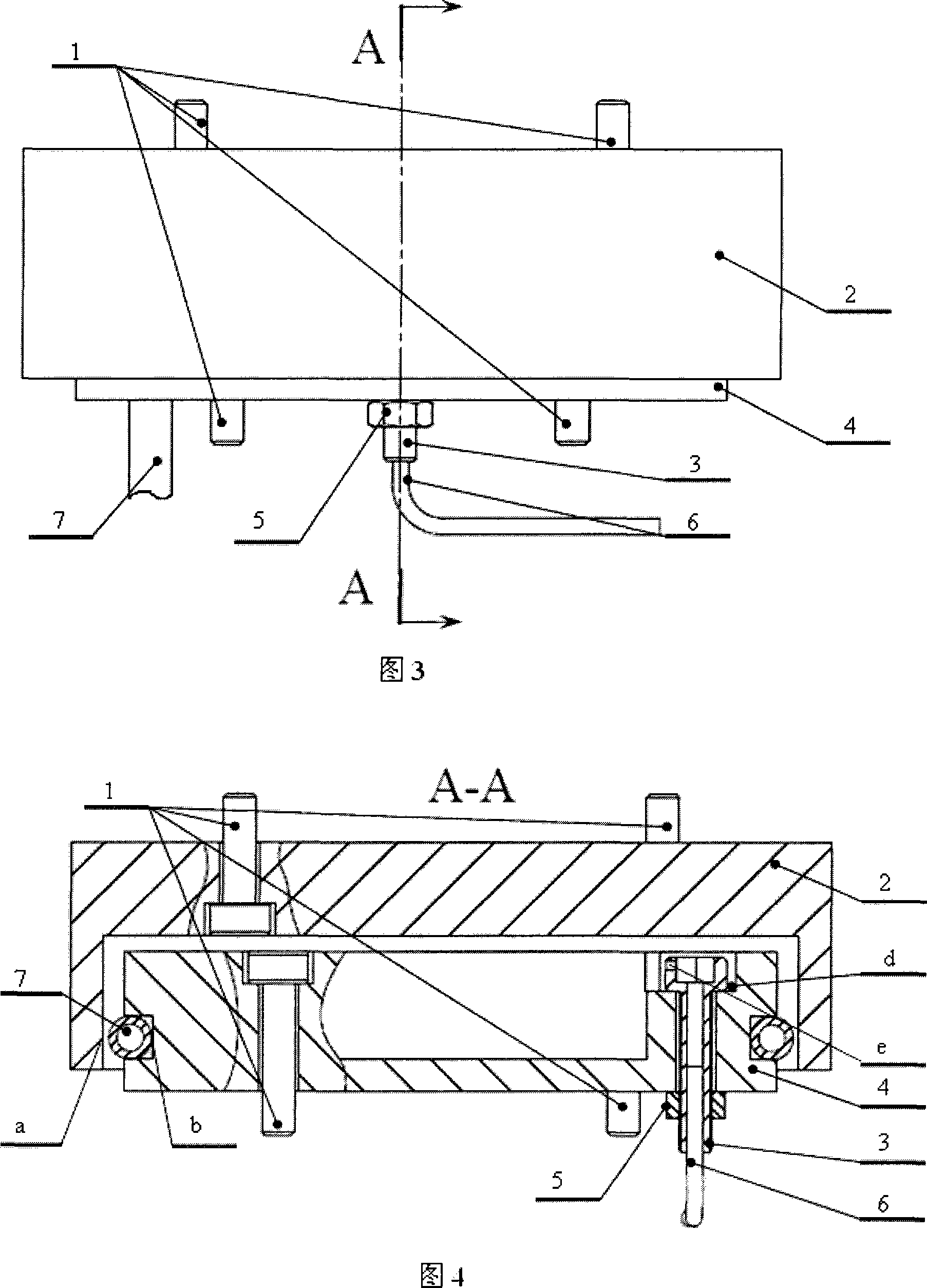

[0018] As shown in Figures 2 and 7, the head of the hollow sealing bolt 3 is horizontally opened with a small hole e vertically connected with the inner hole, and the small hole e serves as an auxiliary vacuum. The gas-liquid hose closed end 8 of the gas-liquid hose 7 is bonded to the annular groove b of the lower sealing chamber 4, and the tube is wound counterclockwise in the annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com