Hypsizigus marmoreus industrial planting method and mushroom house system using thereof

A cultivation method and technology of shimeji mushrooms, applied in the field of cultivating shimeji mushrooms, can solve the problems of not being able to grow shimeji mushrooms the fastest, easily distorting the shape of shimeji mushrooms, uneven drying and wetness of the mushroom room, etc. Production cycle, uniform air humidity, and the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

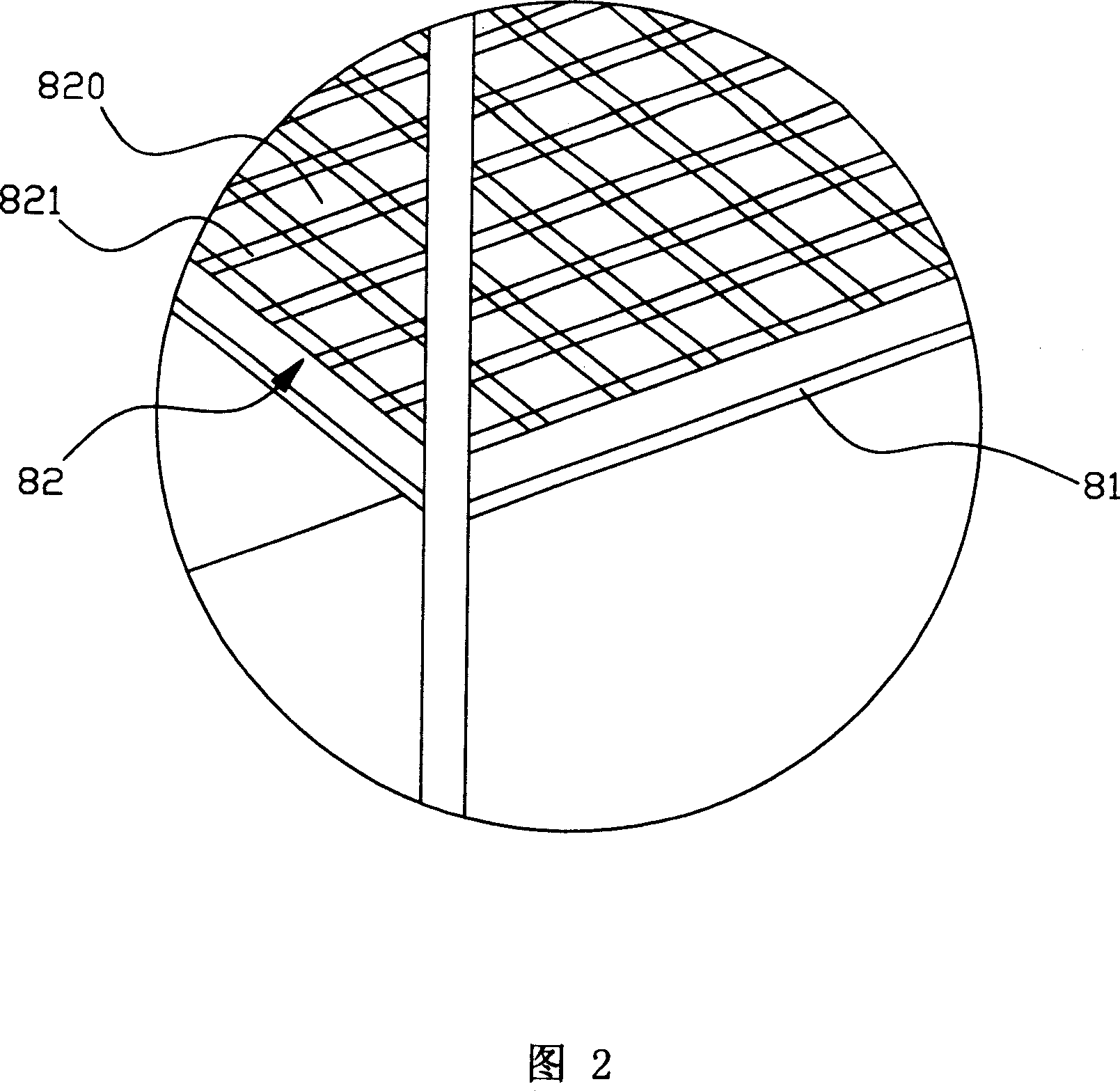

[0020] A specific embodiment of the present invention will be described below with reference to FIG. 1 and FIG. 2 .

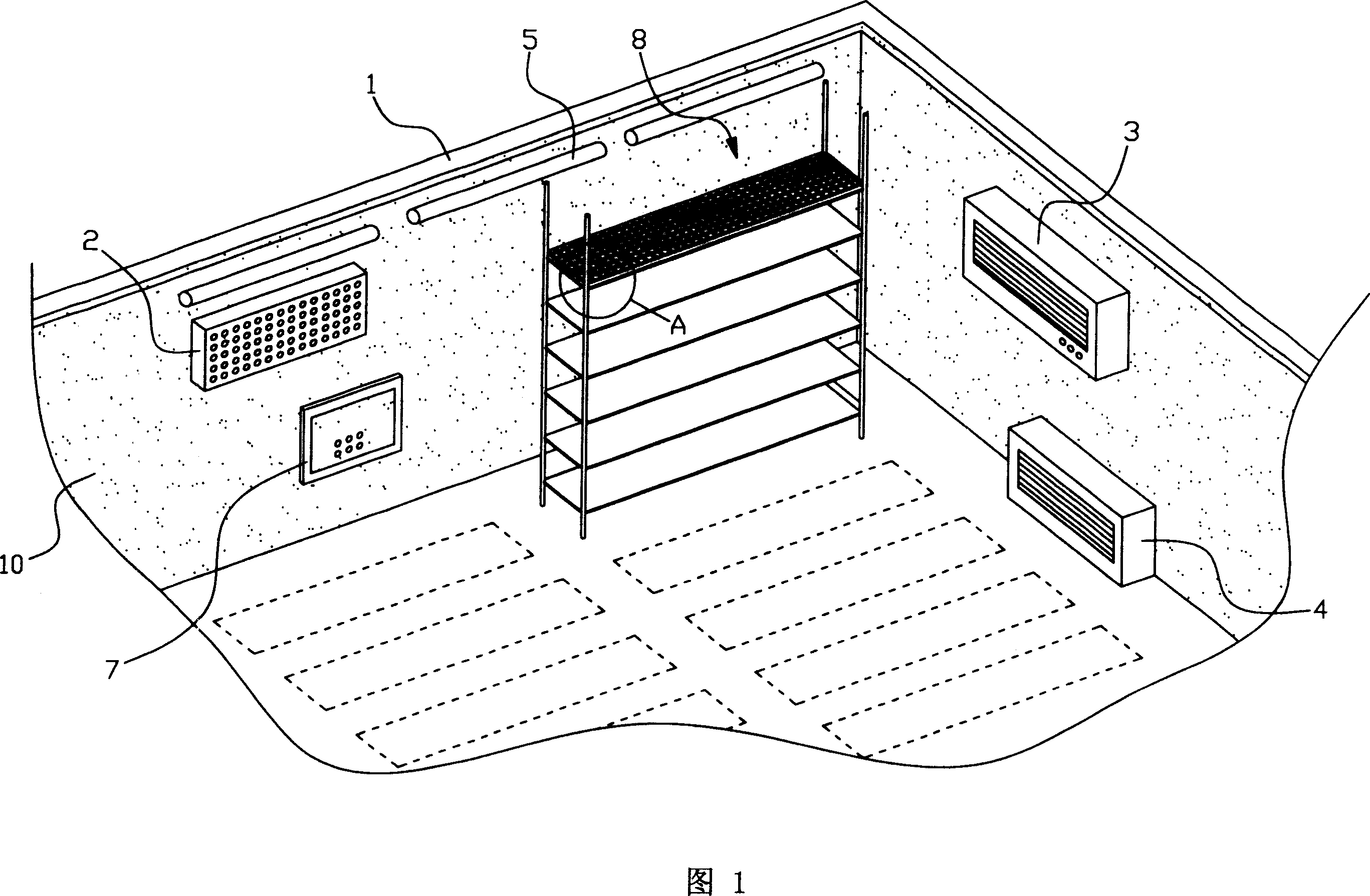

[0021] Referring to Fig. 1 , the mushroom house system used for the industrial cultivation of shimeji mushrooms includes a mushroom house 1 and an air exchanger 2 located in the mushroom house 1, a cooling fan 3, an ultrasonic humidifier 4, a lighting system 5, and a central control system 7 And mushroom bed8.

[0022] Wherein, a heat insulation layer 10 is pasted on the inner wall and roof of the mushroom house 1, and the heat insulation layer 10 is a foam board with a thickness of more than 5 cm. In FIG. 1 , the roof of the mushroom house 1 is not shown in order to see the internal structure of the mushroom house 1 clearly. The air cooler 3 regularly cools the environment in the mushroom house 1, so that the temperature in the mushroom house 1 is controlled within the required range; the air exchanger 2 is installed on the wall of the mushroom house 1, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com