Intelligent bearing with compound sensor

A composite sensor and bearing technology, applied in the direction of shaft and bearing, bearing components, bearing assembly, etc., can solve the problems of assembly difficulty, stress concentration, poor wire layout, etc., and achieve the effect of reasonable layout, simple signal transmission and processing circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

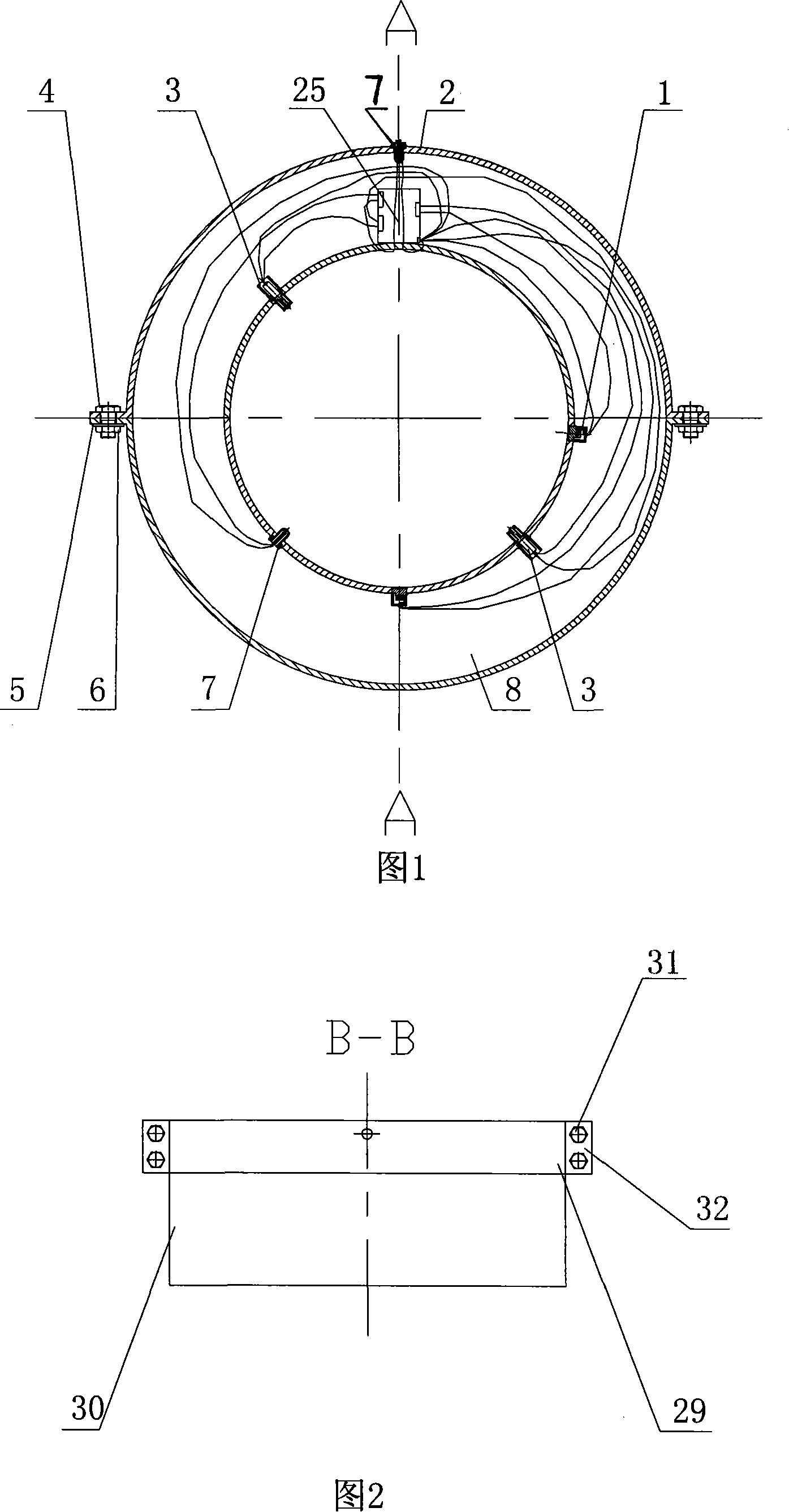

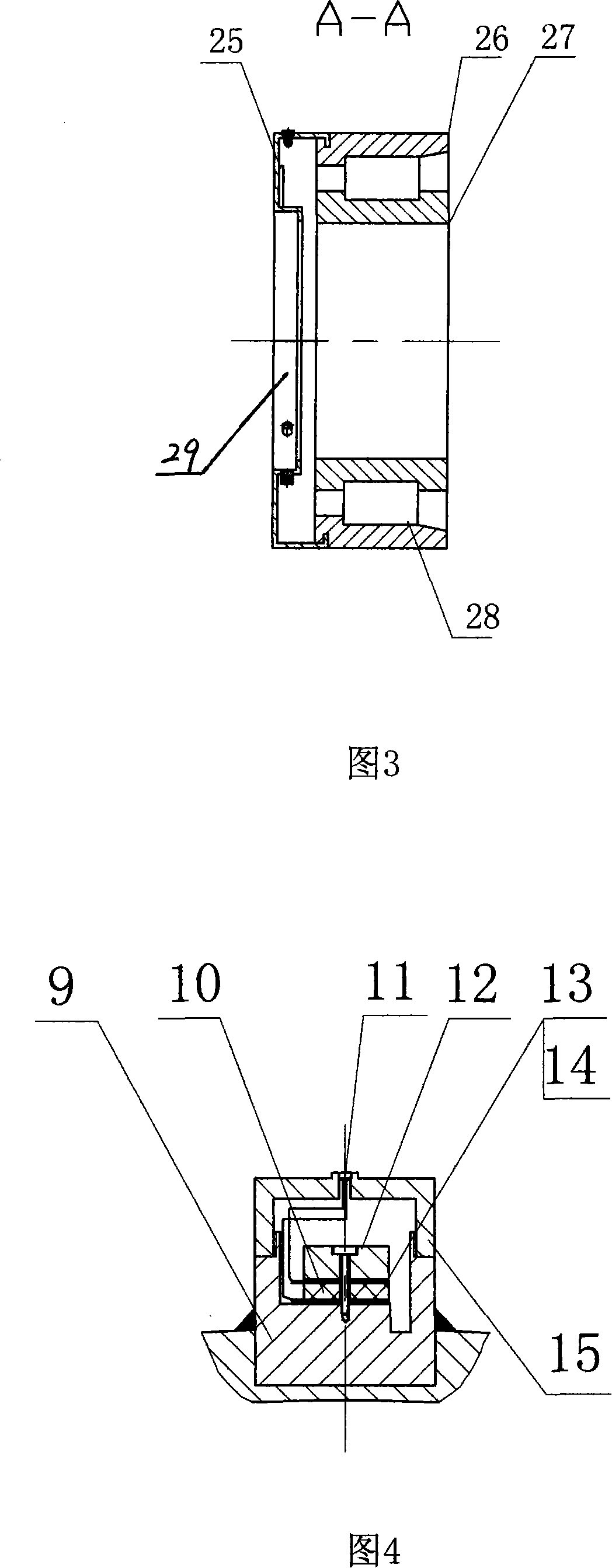

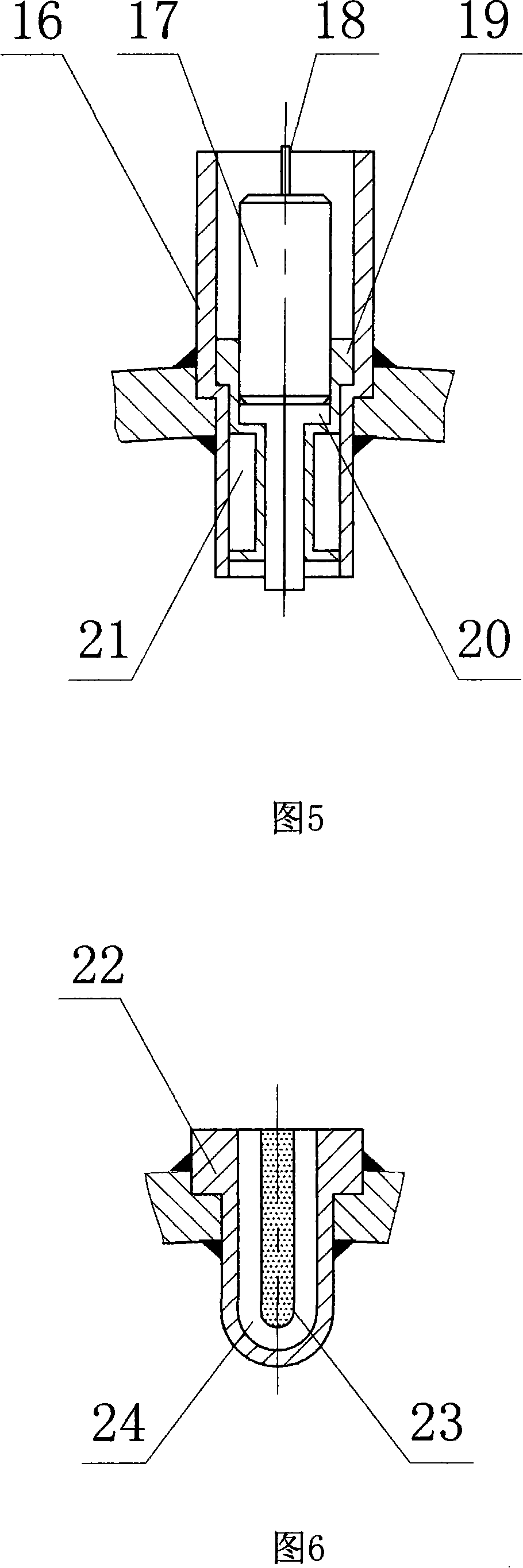

[0037] Please refer to Fig. 1, Fig. 2, Fig. 3, the present invention mainly consists of a bearing 30 and a composite sensor 29 installed on the end face of the bearing 30, the composite sensor is docked by two upper semicircular shells 2 and lower semicircular shells 8 of the same shape A disc housing with a through hole in the center is formed. The inner and outer rings of the disc housing are bent and extended in the same direction to form bosses, and a circuit board 25 is installed on the housing between the two bosses. An acceleration sensing device 1, a speed sensing device 3, and a temperature sensing device 7 are embedded on the boss of the inner ring of the disc housing, and another Temperature sensing device 7 ; the output lines of the sensing devices 1 , 3 , 7 are respectively connected to the input terminals of the amplifiers on the circuit board 25 , and the signals are output after being processed by the amplifiers.

[0038] As shown in Figure 1: two acceleration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com